Loading ...

Loading ...

Loading ...

It,_a_r, mo =I_ hT_ _ a

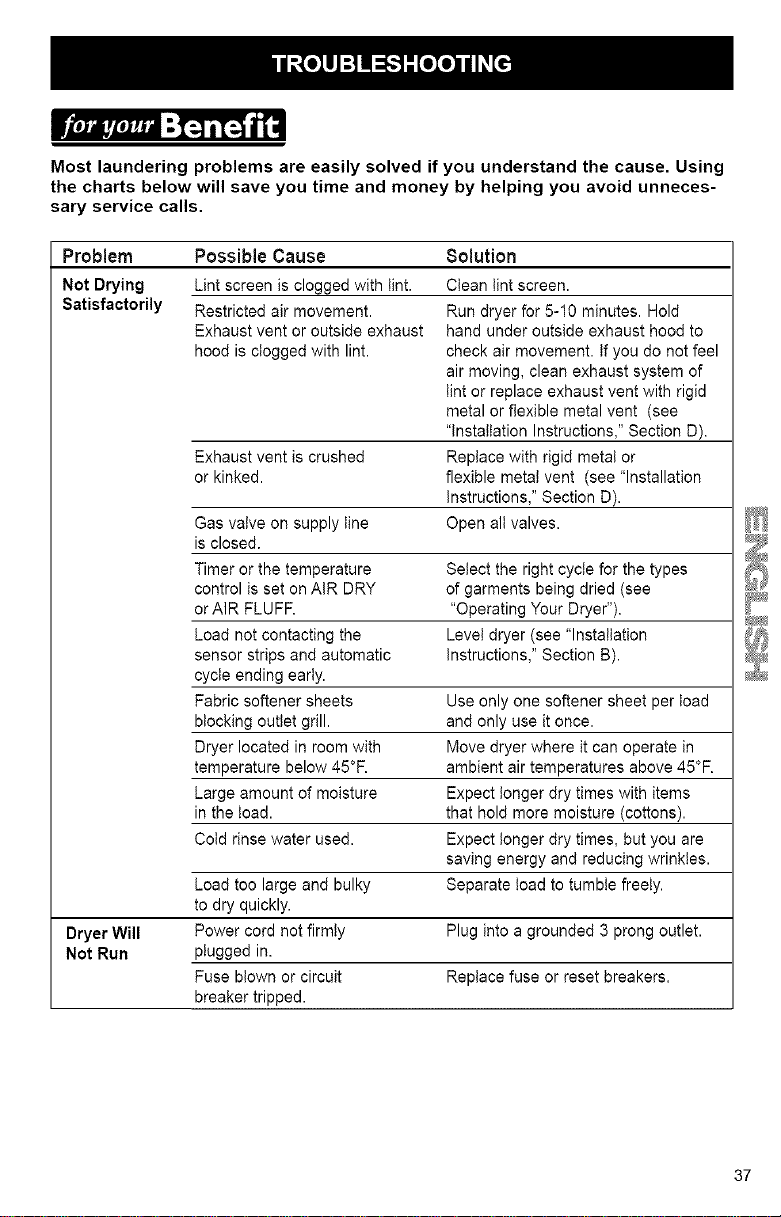

Most laundering problems are easily solved if you understand the cause. Using

the charts below will save you time and money by helping you avoid unneces-

sary service calls.

Problem

Not Drying

Satisfactorily

8olution

Clean tint screen.

Run dryer for 5-10 minutes. Hold

hand under outside exhaust hood to

check air movement, tf you do not feel

air moving, clean exhaust system of

tint or replace exhaust vent with rigid

metal or flexible metal vent (see

"installation Instructions," Section D).

Exhaust vent is crushed Replace with rigid metal or

or kinked, flexible metal vent (see "Installation

Instructions," Section D).

Gas valve on supply line Open alt valves.

is closed.

Timer or the temperature Select the right cycle for the types

control is set on AIR DRY of garments being dried (see

orAIR FLUFF. "Operating Your Dryer").

Load not contacting the Level dryer (see "Installation

sensor strips and automatic Instructions," Section B).

cycle ending early.

Fabric softener sheets Use only one softener sheet per toad

blocking outlet grill, and only use it once.

Dryer located in room with Move dryer where it can operate in

temperature below 45°R ambient air temperatures above 45°F.

Large amount of moisture Expect longer dry times with items

in the toad. that hold more moisture (cottons).

Cold rinse water used. Expect longer dry times, but you are

saving energy and reducing wrinkles.

Load too large and bulky Separate toad to tumble freely.

to dry quickly.

Dryer Will Power cord not firmly Plug into a grounded 3 prong outlet.

Not Run plugged in.

Fuse btown or circuit Replace fuse or reset breakers.

breaker tripped.

PossibleCause

Lint screen is clogged with tint.

Restricted air movement.

Exhaust vent or outside exhaust

hood is clogged with lint.

37

Loading ...

Loading ...

Loading ...