Loading ...

Loading ...

Loading ...

6 32 590 16 Rev. AKohlerEngines.com

7. Reinstall oil fi ll cap/dipstick and tighten

securely.

8. Start engine; check for oil leaks. Stop engine;

correct leaks. Recheck oil level.

9. Dispose of used oil and fi lter in accordance

with local ordinances.

Oil Sentry™ (if equipped)

This switch is designed to prevent engine

from starting in a low oil or no oil condition. Oil

Sentry™ may not shut down a running engine

before damage occurs. In some applications

this switch may activate a warning signal. Read

your equipment manuals for more information.

Fuel Recommendations

WARNING

Explosive Fuel can cause fi res

and severe burns.

Do not fi ll fuel tank while engine is

hot or running.

Gasoline is extremely fl ammable and

its vapors can explode if ignited. Store

gasoline only in approved containers, in

well ventilated, unoccupied buildings, away

from sparks or fl ames. Spilled fuel could

ignite if it comes in contact with hot parts or

sparks from ignition. Never use gasoline as a

cleaning agent.

NOTE: E15, E20 and E85 are NOT approved

and should NOT be used; effects of

old, stale or contaminated fuel are not

warrantable.

Fuel must meet these requirements:

● Clean, fresh, unleaded gasoline.

● Octane rating of 87 (R+M)/2 or higher.

● Research Octane Number (RON) 90 octane

minimum.

● Gasoline up to 10% ethyl alcohol, 90%

unleaded is acceptable.

● Methyl Tertiary Butyl Ether (MTBE) and

unleaded gasoline blend (max 15% MTBE by

volume) are approved.

● Do not add oil to gasoline.

● Do not overfi ll fuel tank.

● Do not use gasoline older than 30 days.

Fuel Line

Low permeation fuel line must be installed on

carbureted Kohler Co. engines to maintain EPA

and CARB regulatory compliance.

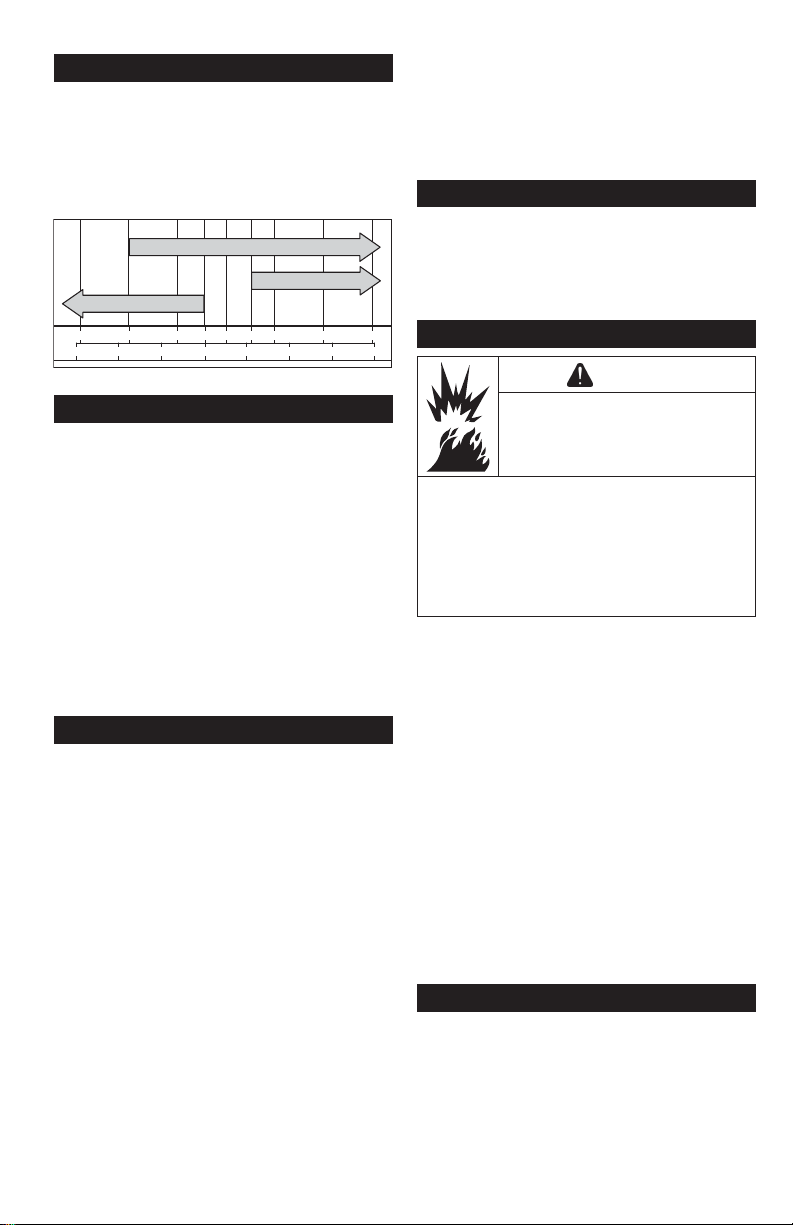

Oil Recommendations

We recommend use of Kohler oils for best

performance. Other high-quality detergent

oils (including synthetic) of API (American

Petroleum Institute) service class SJ or higher

are acceptable. Select viscosity based on air

temperature at time of operation as shown in

table below.

°F -20 020324060

50 80 100

°C -30 -20 -10 0 10 20 30 40

5W-30

10W-30

SAE 30

Check Oil Level

NOTE: To prevent extensive engine wear or

damage, never run engine with oil level

below or above operating range

indicator on dipstick.

Ensure engine is cool. Clean oil fi ll/dipstick

areas of any debris.

1. Remove dipstick; wipe oil off.

2. Reinsert dipstick into tube; press completely

down.

3. Remove dipstick; check oil level. Level

should be at top of indicator on dipstick.

4. If oil is low on indicator, add oil up to top of

indicator mark.

5. Reinstall and secure dipstick.

Change Oil and Filter

Change oil while engine is warm.

1. Clean area around oil fi ll cap/dipstick.

Remove drain plug and oil fi ll cap/dipstick.

Allow oil to drain completely.

2. Clean area around oil fi lter. Place a container

under fi lter to catch any oil and remove fi lter.

Wipe off mounting surface. Reinstall drain

plug. Torque to 10 ft. lb. (13.6 N·m).

3. Place new fi lter in shallow pan with open end

up. Fill with new oil until oil reaches bottom

of threads. Allow 2 minutes for oil to be

absorbed by fi lter material.

4. Apply a thin fi lm of clean oil to rubber gasket

on new fi lter.

5. Refer to instructions on oil fi lter for proper

installation.

6. Fill crankcase with new oil. Level should be

at top of indicator on dipstick.

Loading ...

Loading ...

Loading ...