Loading ...

Loading ...

Loading ...

Maintenance

Owner’s Manual for 60 Hz Air-Cooled Generators 33

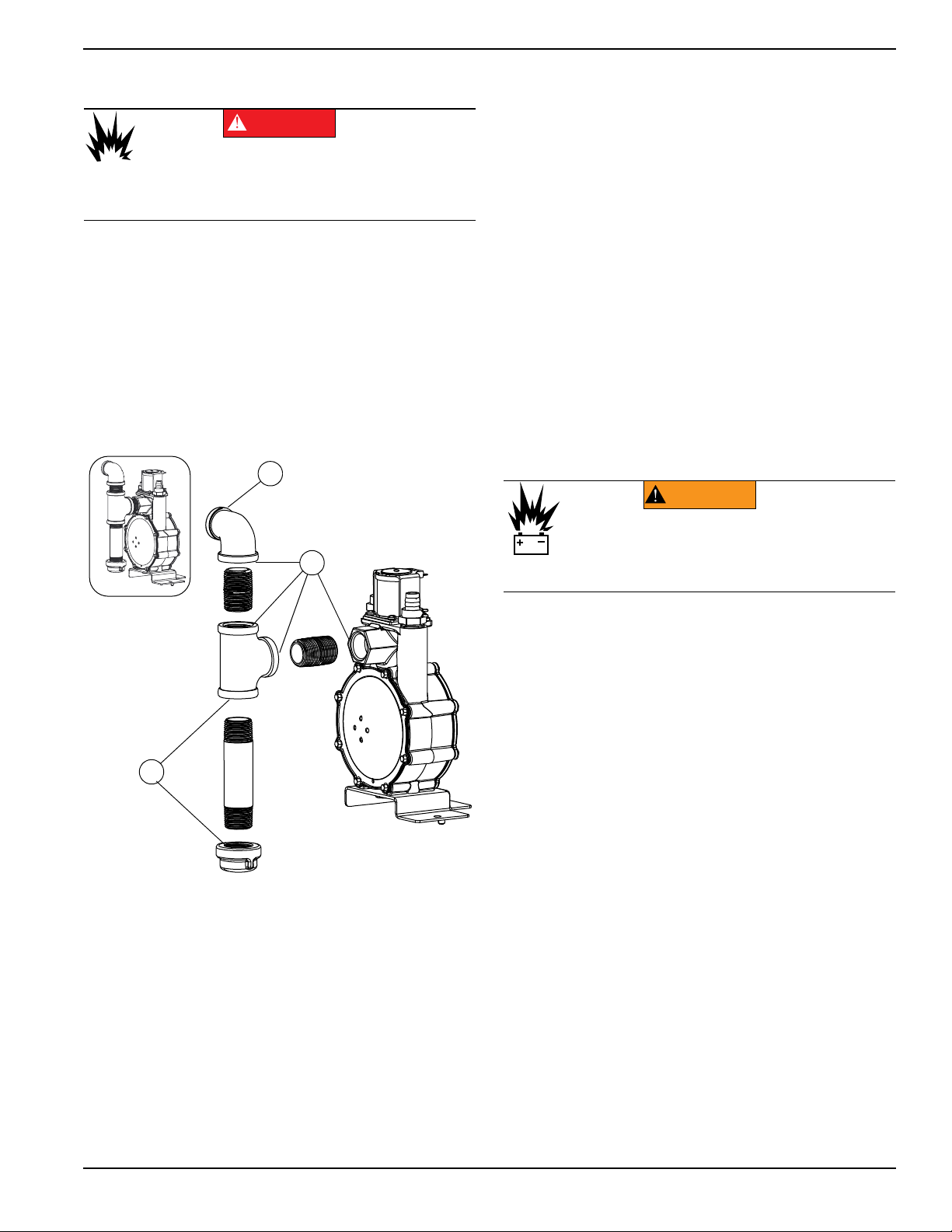

Performing Fuel System Leak Test

All products are factory-tested before shipping to verify

the performance and integrity of the fuel system. How

-

ever, it is important to perform a final fuel system leak test

before starting the generator. The entire fuel system

should be tested from supply to regulator.

See Figure 4-12. Perform a final fuel system leak test

after generator installation. The test will identify possible

leaks at all connection points (A).

It is best practice to perform a fuel system leak test

during normally-scheduled maintenance.

Figure 4-12. Connection Points to Leak Check

Inspect for leaks by spraying all connection points with a

non-corrosive gas leak detection fluid. The solution

should not be blown away or form bubbles.

Attention After Submersion

DO NOT start or operate generator if it has been sub-

merged in water. Have an IASD thoroughly clean, dry,

and inspect generator following any submersion in water.

If the structure (home) has been flooded, it should be

inspected by a certified electrician to verify there will not

be any electrical problems during generator operation or

when utility power is returned.

Corrosion Protection

Regular scheduled maintenance should be conducted to

inspect unit for corrosion. Inspect all metal components

of generator, including base frame, brackets, alternator

can, the entire fuel system (inside and outside of the gen

-

erator), and fastener locations. If there is corrosion found

on generator components (e.g. regulator, engine/alterna

-

tor mounts, fuel plenum, etc.), replace parts as neces-

sary.

Periodically wash and wax enclosure using automotive

type products. Do not spray unit with a hose or power

washer. Use warm, soapy water and a soft cloth. Fre

-

quent washing is recommended in salt water/coastal

areas. Spray engine linkages with a light oil such as WD-

40.

Remove From and Return To Service

Procedure

Remove From Service

If generator cannot be exercised monthly, at a minimum,

and will be out of service longer than 90 days, proceed as

follows to prepare generator for storage:

1. Start engine and allow it to warm up.

2. Close fuel shutoff valve in fuel supply line and

allow engine to stop.

3. Set generator MLCB (generator disconnect) to

OFF (OPEN) once engine has stopped.

4. Disconnect battery charger AC input T1/Neutral

cable (with white sleeve) at controller.

5. Remove 7.5A fuse from generator control panel.

6. Disconnect battery cables. Remove negative bat-

tery cable first.

7. Drain oil completely while engine is still warm, and

then fill crankcase with oil. See

Changing the Oil

and Oil Filter.

8. Attach a tag to engine indicating viscosity and clas-

sification of the new oil in the crankcase.

9. Remove spark plug(s) and spray a fogging agent

into spark plug(s) threaded openings. Install and

tighten spark plug(s) to specification.

10. Remove battery and store in a cool, dry place.

11. Clean and wipe down generator enclosure.

(000192)

DANGER

Explosion and fire. Fuel and vapors are extremely

flammable and explosive. No leakage of fuel is

permitted. Keep fire and spark away. Failure to do

so will result in death or serious injury.

A

A

A

004038

(000238)

Explosion. Batteries emit explosive gases.

Always disconnect negative battery cable

first to avoid spark. Failure to do so could

result in death or serious injury.

WARNING

Loading ...

Loading ...

Loading ...