Loading ...

IMPORTANT

For Non-ducted (Duct free) Installation:

a) Purchase non-ducted filter separately, model 41F.

b) Remove and discard damper/duct connector and grille cover

(See Step 3 in “Preparing the range Hood,” on page 3).

c) Follow all steps except steps inside dotted lines.

For Ducted Installation:

Follow all steps, including steps inside dotted lines.

Begin planning ductwork by deciding where the duct will run between

the range hood and the outside. For best performance, use the shortest

possible duct run and a minimum number of elbows. There are several

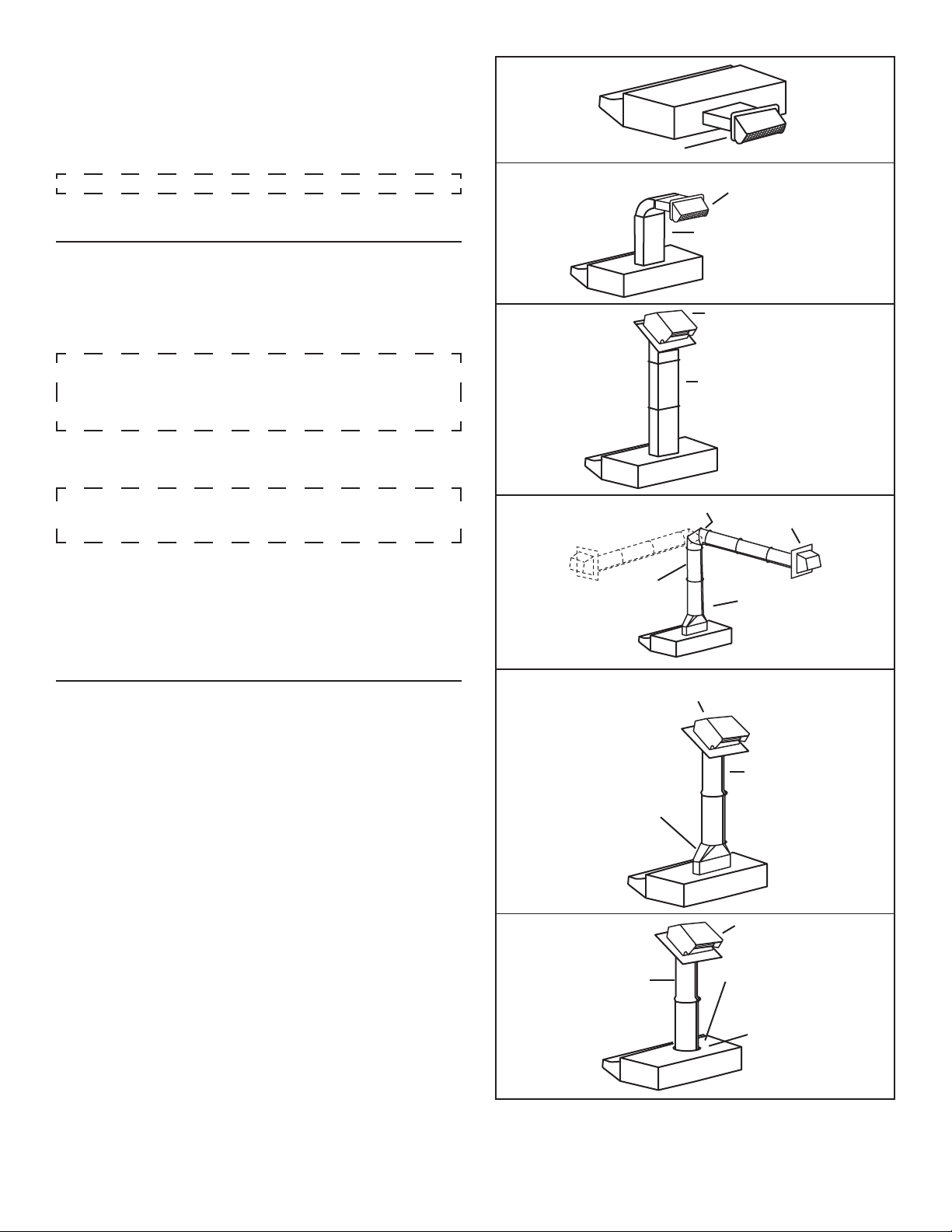

choices shown - FIGS. 1A - 1F.

If needed, a 3¼” x 10” rectangular ducting range hood can be converted to

a round duct by means of a transition.

FIG. 1A. Ducting directly through the wall (for range hoods mounted on an

exterior wall). Shown are two ways to duct through an outside wall. If a wall

cap is used directly off the back of the hood, special care must be taken to

make sure that the damper in the damper/duct connector on the hood and

damper in the wall cap do not interfere with each other when the hood is

operating. This could result in either inadequate air delivery or back drafts.

If this condition does exist, remove the hood damper flap. Sometimes when

using a wall cap it is easier to duct vertically and then use an elbow as

shown in FIG. 1B.

FIG. 1C. Ducting straight up through the roof using 3¼” x 10” rectangular

duct. (For single story installations.)

FIG. 1D. Ducting between the ceiling joists (for multi-story installations) or

through the soffit space above the cabinets (where the soffit connects to

an outside wall).

FIG. 1E. Straight up through the roof using 3¼” x 10” to 6” round duct

transition and 6” round duct (for single-story installations).

FIG. 1F. Straight up through the roof using 7” round duct (for single-story

installations, 7” round adapter plate not included, part number SR680508).

PLANNING DUCTWORK INSTALLATION

TOOLS

Drill

1¼" Spade bit

Pliers

Flat blade and

Phillips screwdriver

Tape measure or ruler

and pencil

TOOLS AND MATERIAL REQUIRED

For ducted installations ONLY:

Saber saw

Metal snips

MATERIALS

Electrical wiring and supplies of type to comply with local codes

Roof or wall cap

Roof cement or caulk

Duct and metal foil duct tape

For installation on kitchen cabinets with recess bottoms only:

Two 1" x 2" x 12" (approximate length) wood strips (purchase locally)

Four 1¼" long flat heat wood screws (purchase locally) to fasten

strips to cabinet bottom

FIG. 1A

WALL CAP 639 OR 649

FIG. 1B

WALL CAP 639 OR 649

3¼” X 10” DUCT 401

FIG. 1C

ROOF CAP 634 OR 644

3¼” X 10” DUCT 401

FIG. 1D

ADJUSTABLE ELBOW 419

WALL CAP 641

3¼” X 10” TO 6” ROUND

DUCT

TRANSITION 411

6” ROUND DUCT 406

FIG. 1E

ROOF CAP 634 OR 644

6” ROUND DUCT 406

3¼” X 10” TO 6” ROUND

DUCT

TRANSITION 411

FIG. 1F

ROOF CAP 634 OR 644

7” ROUND DUCT 407

OPTIONAL DAMPER

MODEL BP87

7” ROUND DUCT PLATE

SR680508

- 2 -

Loading ...

Loading ...

Loading ...