Loading ...

Loading ...

Loading ...

1. Before each use, inspect the general condi-

tion of the jack. Check for broken, cracked,

or bent parts, loose or missing parts, and

any condition that may affect the proper

operation of the product. Any jack that ap-

pears damaged in anyway must be removed

from service. Have the problem corrected

before further use. DO NOT use damaged

equipment.

2. Replace worn or damaged parts with Perfor-

mance Tool replacement parts. Be sure that

only qualied personnel perform repairs.

3. Before each use, thoroughly test the jack

for proper operation prior to its actual use. If

the jack appears not to be working properly,

follow bleeding instructions.

4. When jack is not in use, ram and pump pis-

ton should be in fully down position to keep

their machined surfaces free from corrosion.

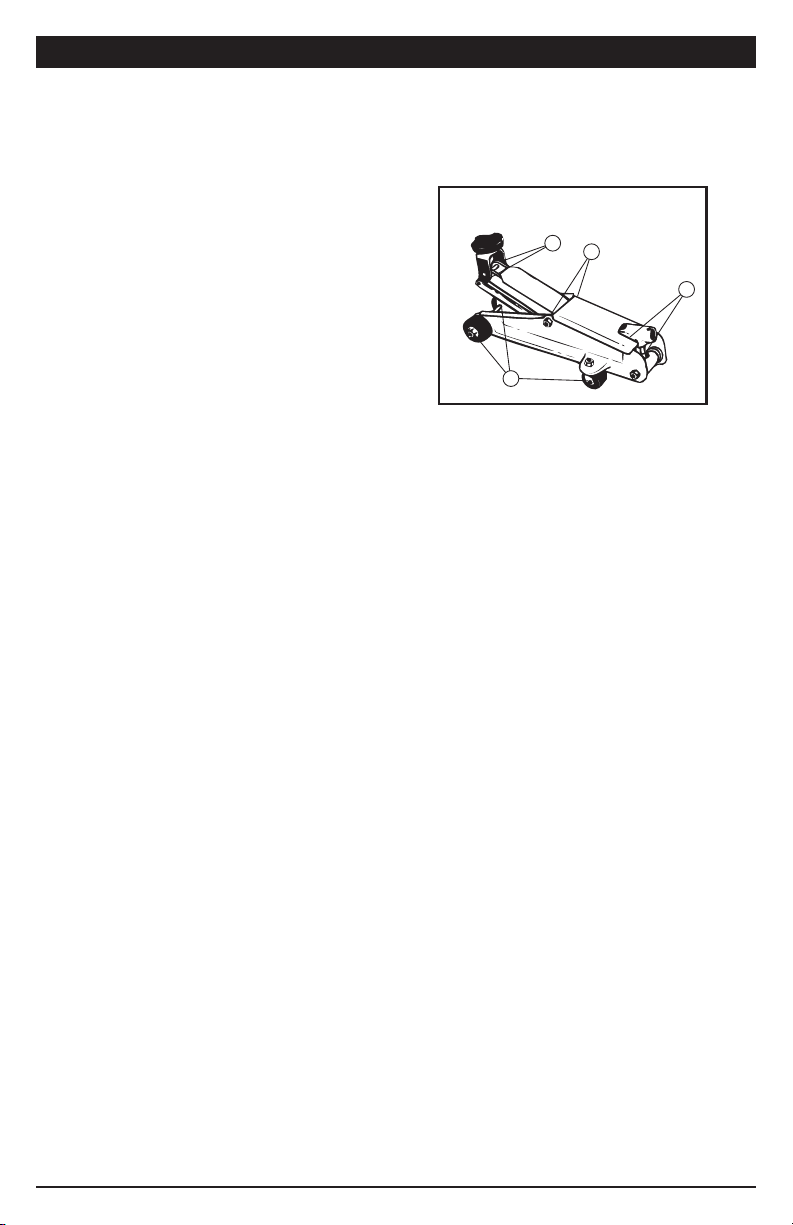

5. Keep jack clean and well lubricated at points

illustrated in gure 3.

1

2

3

4

Figure 3

CARE & MAINTENANCE

Monthly maintenance is recommended. Lubrication is critical to jacks as they support

heavy loads. Any restriction due to dirt, rust, etc. can cause either slow movement or

cause extremely rapid jerks, damaging the internal components. The following steps are

designed to keep the jack maintained and operational.

6. For best results, use only hydraulic uid with

a rating of SAE 20 for rells.

7. Change the hydraulic oil at least once every

three years:

a. Fully retract the ram by turning the release

valve counter-clockwise.

b. Loose the four top plate retaining screws (no

need screw out) and remove the top plate

vertically.

c. With the jack in the level position, remove the

oil ller plug.

d. The proper oil volume should be the maxi-

mum distance from the oil surface level to

the top of oil tank should be less than 13mm.

If the oil is not enough, please add high quali-

ed hydraulic oil.

e. Replace the oil ller plug.

f. After adding oil, please checking if the jack

can reach the maximum height with seven

pumps, if not, please purge air from the

hydraulic unit as required.

g. Cover the top plate, please make sure the

four grooves in the top plate mate four retain-

ing screws. Then tightening the four screws.

CHANGING OIL

a. Fully retract the ram by turning the release

valve counter-clockwise.

b. Loose the four top plate retaining screws (no

need screw out) and remove the top plate

vertically.

c. Unscrew the hexagon socket screw, and take

out the oil tank vertically by hand.

d. Remove the oil ller plug and turn the oil tank

up-side down. Press the oil valve (please

note never cover the hole on the oil valve

when pressing it) and then empty the oil tank.

HOW TO PRESS THE OIL VALVE

Note: Dispose of hydraulic oil in accordance with

local regulations.

1. Add 400ml high qualied hydraulic oil to the

oil tank.

2. Replace the oil ller plug, put the oil tank

back to the pump base and lock it by the

hexagon screw.

3. Recover the top plate, then tighten the retain-

ing screws.

4. After adding oil, please check if there any air

in the hydraulic system. Close the release

valve clockwise, pumping the handle with full

stroke, if the jack can’t reach the maximum

height with 7 pumps, do purging process.

5

Loading ...

Loading ...

Loading ...