Loading ...

Loading ...

Loading ...

English

15

tioned between the spindle and the operator to provide maxi-

mum operator protection.

4. Close the guard latch to secure the guard on the gear case

cover. You should be unable to rotate the guard by hand when

the latch is in closed position. Do not operate grinder with a

loose guard or clamp lever in open position.

NOTE: The guard is pre-adjusted to the dia-

meter of the gear case hub at the factory. If,

after a period of time, the guard becomes

loose, tighten the adjusting screw (I) with the

clamp lever in the closed position.

CAUTION: Do not tighten adjusting screw

with clamp lever in open position. Undetectable damage to guard

or mounting hub may result.

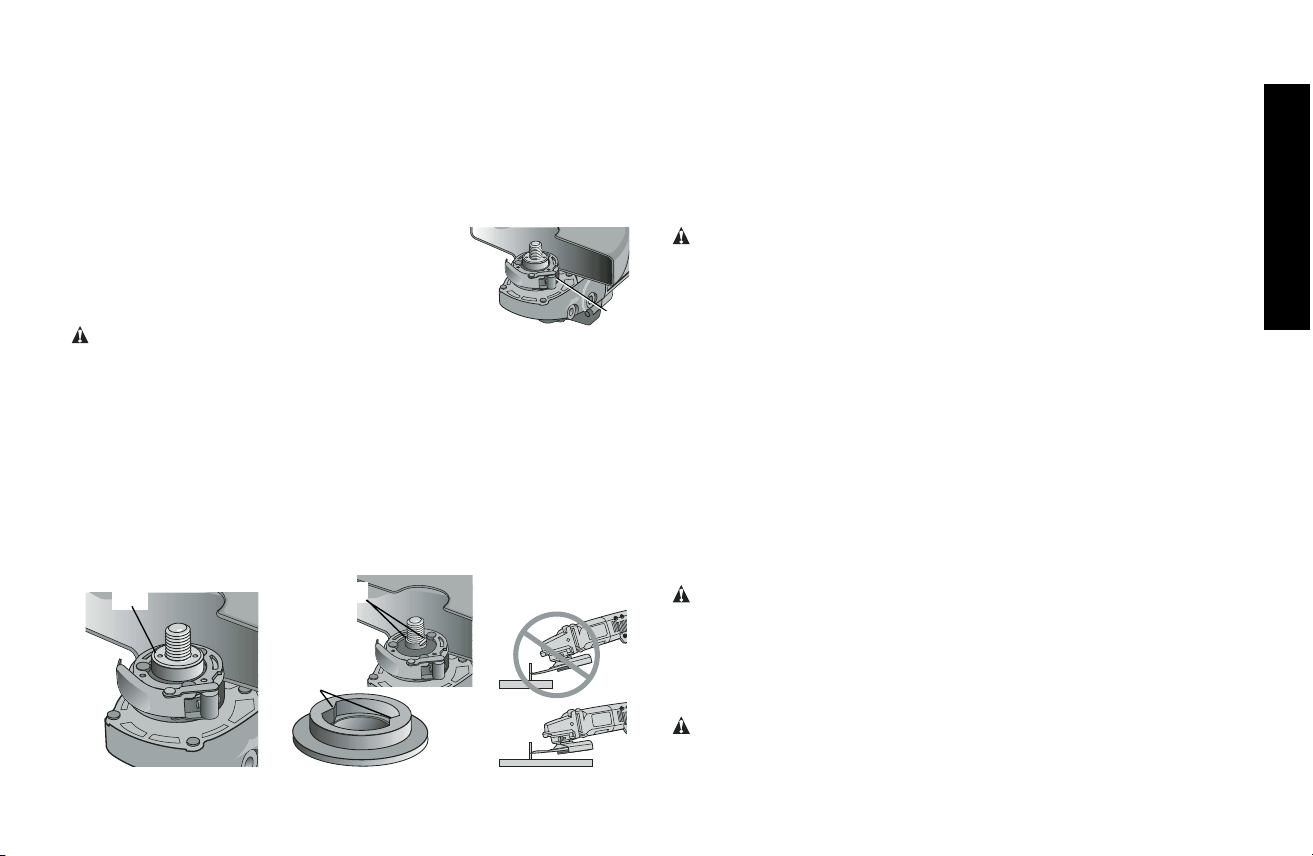

MOUNTING CUTTING WHEELS

1. Remove Soft Mount (F).

2. Install wheel backing flange, aligning flats on spindle (O) with

flats on backing flange (R).

3. Place the wheel on the backing flange, centering the wheel on

the backing flange pilot.

4. Install the clamp nut, ensuring that the wheel remains centered

on the backing flange.

5. Depress the spindle lock button and tighten clamp nut with

wrench.

6. Reverse the above procedure to remove the wheel.

USING CUTTING WHEELS

WARNING:

Do not use edge grinding/cutting wheels for surface

grinding applications because these wheels are not designed for

side pressures encountered with surface grinding. Wheel breakage

and injury may result.

1. Allow tool to reach full speed before touching tool to work

surface.

2. Apply minimum pressure to work surface, allowing tool to oper-

ate at high speed.

3. Once you begin a cut, maintain the angle of the cutting wheel

to the work surface. This will keep you from bending the wheel

which could result in wheel breakage and injury.

4. Remove the tool from work surface before turning tool off. Allow

the tool to stop rotating before setting it down.

MAINTENANCE

Cleaning

WARNING: Blowing dust and grit out of the motor housing using

clean, dry compressed air is a necessary regular maintenance pro-

cedure. Dust and grit containing metal particles often accumulate on

interior surfaces and could create an electrical shock or electrocu-

tion if not frequently cleaned out. ALWAYS WEAR SAFETY

GLASSES.

CAUTION: Never use solvents or other harsh chemicals for

cleaning the non-metallic parts of the tool. Use a clean, dry rag only.

F

O

R

I

Loading ...

Loading ...

Loading ...