Documents: Go to download!

User Manual

- Owner's manual - (English)

- Unit Specifications and Features

- Care and Maintenance

- Troubleshooting

- Accessories

- Installation Summary - Indoor Unit

- Indoor Unit Installation

- Outdoor Unit Installation

- Refrigerant Piping Connection

- Air Evacuation

- Electrical and Gas Leak Checks

- Test Run

Table of contents

Owner’s Manual & Installation Manual split-type room air conditioner for Midea MSAGBU-12HRFN8-QRD1GW(GA)

Unit Specifications and Features

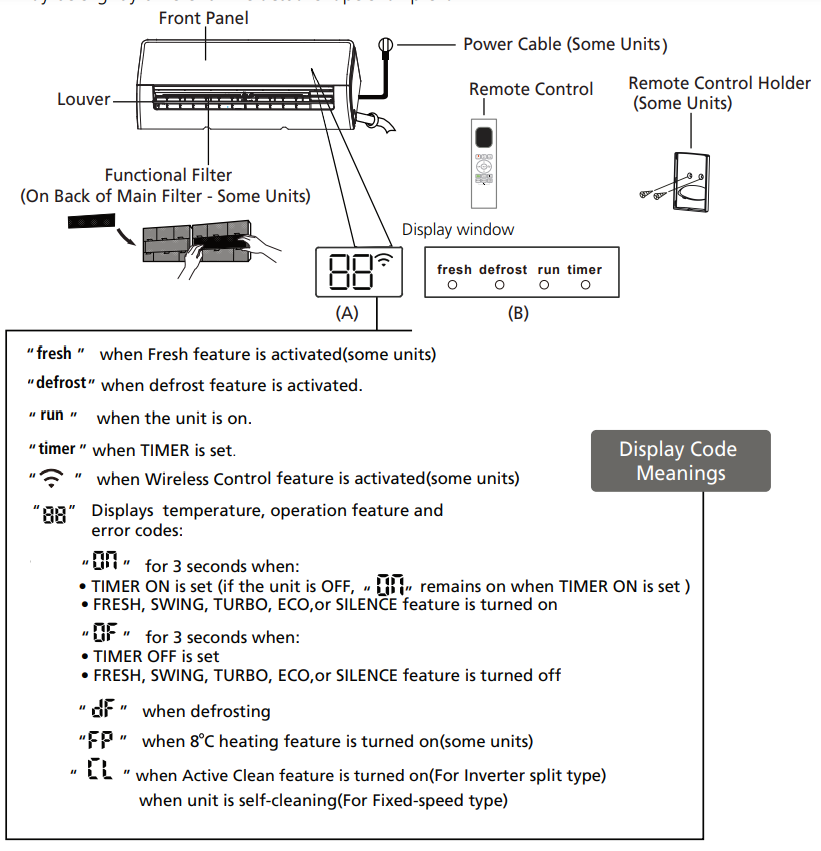

Indoor unit display

- NOTE: Different models have different front panels and display windows. Not all the display codes describing below are available for the air conditioner you purchased. Please check the indoor display window of the unit you purchased.

- Illustrations in this manual are for explanatory purposes. The actual shape of your indoor unit may be slightly different. The actual shape shall prevail.

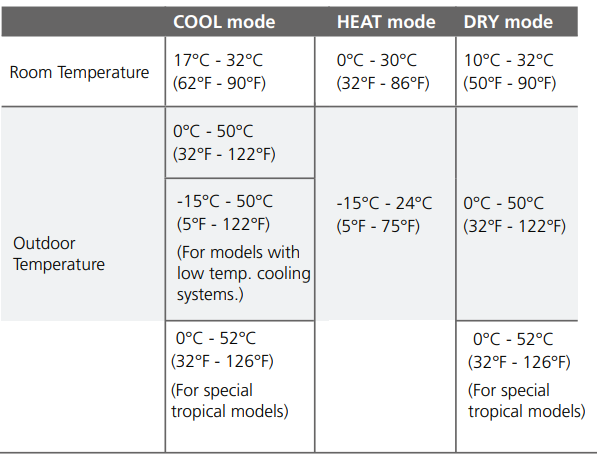

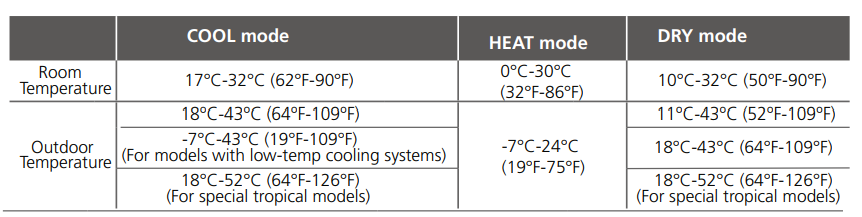

Operating temperature: When your air conditioner is used outside of the following temperature ranges, certain safety protection features may activate and cause the unit to disable.

- Inverter Split Type

FOR OUTDOOR UNITS WITH AUXILIARY ELECTRIC HEATER: When outside temperature is below 0°C (32°F ), we strongly recommend keeping the unit plugged in at all time to ensure smooth ongoing performance.

- Fixed-speed Type

NOTE: Room relative humidity less than 80%. If the air conditioner operates in excess of this figure, the surface of the air conditioner may attract condensation. Please sets the vertical air flow louver to its maximum angle (vertically to the floor), and set HIGH fan mode.

To further optimize the performance of your unit, do the following:

- Keep doors and windows closed.

- Limit energy usage by using TIMER ON and TIMER OFF functions.

- Do not block air inlets or outlets.

- Regularly inspect and clean air filters.

A guide on using the infrared remote is not included in this literature package. Not all the functions are available for the air conditioner, please check the indoor display and remote control of the unit you purchased

Other Features

- Auto-Restart(some units): If the unit loses power, it will automatically restart with the prior settings once power has been restored.

- Anti-mildew (some units): When turning off the unit from COOL, AUTO (COOL), or DRY modes, the air conditioner will continue operate at very low power to dry up condensed water and prevent mildew growth.

- Wireless Control (some units): Wireless control allows you to control your air conditioner using your mobile phone and a wireless connection. For the USB device access, replacement, maintenance operations must be carried out by professional staff.

- Louver Angle Memory(some units): When turning on your unit, the louver will automatically resume its former angle.

- Active Clean function(some units): The Active Clean Technology washes away dust, mold, and grease that may cause odors when it adheres to the heat exchanger by automatically freezing and then rapidly thawing the frost. A “pi-pi” sound will be heard. The Active clean operation is used to produce more condensed water to improve the cleaning effect, and the cold air will blow out. After cleaning, the internal wind wheel then keeps operating with hot air to blow-dry the evaporator, thus preventing the growth of mold and keeping the inside clean. When this function is turned on, the indoor unit display window appears “CL ” , after 20 to 45 minutes, the unit will turn off automatically and cancel Active Clean function.

- Breeze Away (some units): This feature avoids direct air flow blowing on the body and make you feel indulging in silky coolness.

- Refrigerant Leakage Detection (some units): The indoor unit will automatically display “EL0C”or flash LEDS (model dependent ) when it detects refrigerant leakage.

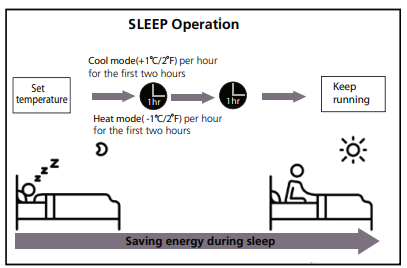

- Sleep Operation: The SLEEP function is used to decrease energy use while you sleep (and don’t need the same temperature settings to stay comfortable). This function can only be activated via remote control. And the Sleep function is not available in FAN or DRY mode. Press the SLEEP button when you are ready to go to sleep. When in COOL mode, the unit will increase the temperature by 1°C (2°F) after 1 hour, and will increase an additional 1°C (2°F) after another hour. When in HEAT mode, the unit will decrease the temperature by 1°C (2°F) after 1 hour, and will decrease an additional 1°C (2°F) after another hour. The sleep feature will stop after 8 hours and the system will keep running with final situation

NOTE: For multi-split air condtioners, the following functions are not available: Active clean function, Silence feature, Breeze away function, Refrigerant leakage detection function and Eco feature.

- Setting Angle of Air Flow

Setting vertical angle of air flow

- While the unit is on, use the SWING/DIRECT button on remote control to set the direction (vertical angle) of airflow. Please refer to the Remote Control Manual for details.

NOTE ON LOUVER ANGLES

- When using COOL or DRY mode, do not set louver at too vertical an angle for long periods of time. This can cause water to condense on the louver blade, which will drop on your floor or furnishings.

- When using COOL or HEAT mode, setting the louver at too vertical an angle can reduce the performance of the unit due to restricted air flow.

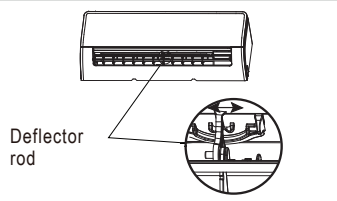

Setting horizontal angle of air flow

- The horizontal angle of the airflow must be set manually. Grip the deflector rod (See Fig.B) and manually adjust it to your preferred direction. For some units, the horizontal angle of the airflow can be set by remote control. please refer to the Remote Control Manual

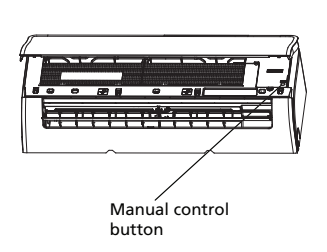

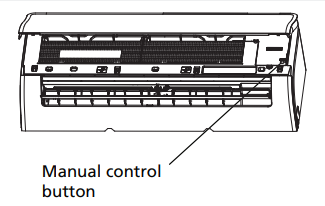

Manual Operation(without remote)

CAUTION: The manual button is intended for testing purposes and emergency operation only. Please do not use this function unless the remote control is lost and it is absolutely necessary. To restore regular operation, use the remote control to activate the unit. Unit must be turned off before manual operation.

To operate your unit manually:

- Open the front panel of the indoor unit.

- Locate the MANUAL CONTROL button on the right-hand side of the unit.

- Press the MANUAL CONTROL button one time to activate FORCED AUTO mode.

- Press the MANUAL CONTROL button again to activate FORCED COOLING mode.

- Press the MANUAL CONTROL button a third time to turn the unit off. 6.Close the front panel.

NOTE: Do not move louver by hand. This will cause the louver to become out of sync. If this occurs, turn off the unit and unplug it for a few seconds, then restart the unit. This will reset the louver.

CAUTION: Do not put your fingers in or near the blower and suction side of the unit. The high-speed fan inside the unit may cause injury.

Care and Maintenance

1. Cleaning Your Indoor Unit

BEFORE CLEANING OR MAINTENANCE: ALWAYS TURN OFF YOUR AIR CONDITIONER SYSTEM AND DISCONNECT ITS POWER SUPPLY BEFORE CLEANING OR MAINTENANCE.

CAUTION: Only use a soft, dry cloth to wipe the unit clean. If the unit is especially dirty, you can use a cloth soaked in warm water to wipe it clean.

- Do not use chemicals or chemically treated cloths to clean the unit

- Do not use benzene, paint thinner, polishing powder or other solvents to clean the unit. They can cause the plastic surface to crack or deform.

- Do not use water hotter than 40°C (104°F) to clean the front panel. This can cause the panel to deform or become discolored.

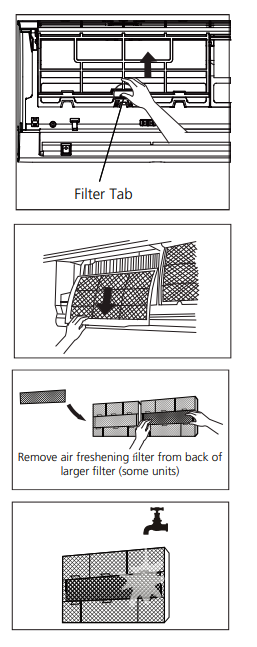

2. Cleaning Your Air Filter: A clogged air conditioner can reduce the cooling efficiency of your unit, and can also be bad for your health. Make sure to clean the filter once every two weeks.

- Lift the front panel of the indoor unit.

- First press the tab on the end of filter to loosen the buckle, lift it up, then pull it towards yourself.

- Now pull the filter out.

- If your filter has a small air freshening filter, unclip it from the larger filter. Clean this air freshening filter with a hand-held vacuum.

- Clean the large air filter with warm, soapy water. Be sure to use a mild detergent.

- Rinse the filter with fresh water, then shake off excess water.

- Dry it in a cool, dry place, and refrain from exposing it to direct sunlight.

- When dry, re-clip the air freshening filter to the larger filter, then slide it back into the indoor unit.

- Close the front panel of the indoor unit.

CAUTION: Do not touch air freshening (Plasma) filter for at least 10 minutes after turning off the unit.

CAUTION

- Before changing the filter or cleaning, turn off the unit and disconnect its power supply.

- When removing filter, do not touch metal parts in the unit. The sharp metal edges can cut you.

- Do not use water to clean the inside of the indoor unit. This can destroy insulation and cause electrical shock.

- Do not expose filter to direct sunlight when drying. This can shrink the filter.

3. Air Filter Reminders (Optional)

Air Filter Cleaning Reminder

- After 240 hours of use, the display window on the indoor unit will flash “CL.” This is a reminder to clean your filter. After 15 seconds, the unit will revert to its previous display.

- To reset the reminder, press the LED button on your remote control 4 times, or press the MANUAL CONTROL button 3 times. If you don’t reset the reminder, the “CL” indicator will flash again when you restart the unit.

Air Filter Replacement Reminder

- After 2,880 hours of use, the display window on the indoor unit will flash “nF.” This is a reminder to replace your filter. After 15 seconds, the unit will revert to its previous display.

- To reset the reminder, press the LED button on your remote control 4 times, or press the MANUAL CONTROL button 3 times. If you don’t reset the reminder, the “nF” indicator will flash again when you restart the unit.

CAUTION

- Any maintenance and cleaning of outdoor unit should be performed by an authorized dealer or a licensed service provider.

- Any unit repairs should be performed by an authorized dealer or a licensed service provider.

4. Maintenance – Long Periods of Non-Use

If you plan not to use your air conditioner for an extended period of time, do the following:

Clean all filters

Turn on FAN function until unit dries out completely

Turn off the unit and disconnect the power

Remove batteries from remote control

5. Maintenance – Pre-Season Inspection

After long periods of non-use, or before periods of frequent use, do the following:

Check for damaged wires

Clean all filters

Check for leaks

Replace batteries

Make sure nothing is blocking all air inlets and outlets

Troubleshooting

1. Common Issues

The following problems are not a malfunction and in most situations will not require repairs

Unit does not turn on when pressing ON/OFF button

- The Unit has a 3-minute protection feature that prevents the unit from overloading. The unit cannot be restarted within three minutes of being turned off.

The unit changes from COOL/HEAT mode to FAN mode

- The unit may change its setting to prevent frost from forming on the unit. Once the temperature increases, the unit will start operating in the previously selected mode again.

- The set temperature has been reached, at which point the unit turns off the compressor. The unit will continue operating when the temperature fluctuates again.

The indoor unit emits white mist

- In humid regions, a large temperature difference between the room’s air and the conditioned air can cause white mist.

Both the indoor and outdoor units emit white mist

- When the unit restarts in HEAT mode after defrosting, white mist may be emitted due to moisture generated from the defrosting process.

The indoor unit makes noises

- A rushing air sound may occur when the louver resets its position.

- A squeaking sound may occur after running the unit in HEAT mode due to expansion and contraction of the unit’s plastic parts

Both the indoor unit and outdoor unit make noises

- Low hissing sound during operation: This is normal and is caused by refrigerant gas flowing through both indoor and outdoor units.

- Low hissing sound when the system starts, has just stopped running, or is defrosting: This noise is normal and is caused by the refrigerant gas stopping or changing direction.

- Squeaking sound: Normal expansion and contraction of plastic and metal parts caused by temperature changes during operation can cause squeaking noises.

The outdoor unit makes noises

- The unit will make different sounds based on its current operating mode.

Dust is emitted from either the indoor or outdoor unit

- The unit may accumulate dust during extended periods of non-use, which will be emitted when the unit is turned on. This can be mitigated by covering the unit during long periods of inactivity.

The unit emits a bad odor

- The unit may absorb odors from the environment (such as furniture, cooking, cigarettes, etc.) which will be emitted during operations.

- The unit’s filters have become moldy and should be cleaned.

The fan of the outdoor unit does not operate: During operation, the fan speed is controlled to optimize product operation. Operation is erratic, unpredictable, or unit is unresponsive Interference from cell phone towers and remote boosters may cause the unit to malfunction. In this case, try the following:

- Disconnect the power, then reconnect.

- Press ON/OFF button on remote control to restart operation.

NOTE: If problem persists, contact a local dealer or your nearest customer service center. Provide them with a detailed description of the unit malfunction as well as your model number.

2. Troubleshooting

When troubles occur, please check the following points before contacting a repair company.

Poor Cooling Performance

- Temperature setting may be higher than ambient room temperature: Lower the temperature setting

- The heat exchanger on the indoor or outdoor unit is dirty: Clean the affected heat exchanger

- The air filter is dirty: Remove the filter and clean it according to instructions

- The air inlet or outlet of either unit is blocked: Turn the unit off, remove the obstruction and turn it back on

- Doors and windows are open: Make sure that all doors and windows are closed while operating the unit

- Excessive heat is generated by sunlight: Close windows and curtains during periods of high heat or bright sunshine

- Too many sources of heat in the room (people, computers, electronics, etc.): Reduce amount of heat sources

- Low refrigerant due to leak or long-term use: Check for leaks, re-seal if necessary and top off refrigerant

- SILENCE function is activated (optional function): SILENCE function can lower product performance by reducing operating frequency. Turn off SILENCE function.

The unit is not working

- Power failure: Wait for the power to be restored

- The power is turned off: Turn on the power

- The fuse is burned out: Replace the fuse

- Remote control batteries are dead: Replace batteries

- The Unit’s 3-minute protection has been activated: Wait three minutes after restarting the unit

- Timer is activated: Turn timer off

The unit starts and stops frequently

- There’s too much or too little refrigerant in the system: Check for leaks and recharge the system with refrigerant.

- Incompressible gas or moisture has entered the system. Evacuate and recharge the system with refrigerant

- The compressor is broken: Replace the compressor

- The voltage is too high or too low: Install a manostat to regulate the voltage

Poor heating performance

- The outdoor temperature is extremely low: Use auxiliary heating device

- Cold air is entering through doors and windows: Make sure that all doors and windows are closed during use

- Low refrigerant due to leak or long-term use: Check for leaks, re-seal if necessary and top off refrigerant

Indicator lamps continue flashing. Error code appears and begins with the letters as the following in the window display of indoor unit: E(x), P(x), F(x); EH(xx), EL(xx), EC(xx); PH(xx), PL(xx), PC(xx)

- The unit may stop operation or continue to run safely. If the indicator lamps continue to flash or error codes appear, wait for about 10 minutes. The problem may resolve itself. If not, disconnect the power, then connect it again. Turn the unit on. If the problem persists, disconnect the power and contact your nearest customer service center.

NOTE: If your problem persists after performing the checks and diagnostics above, turn off your unit immediately and contact an authorized service center.

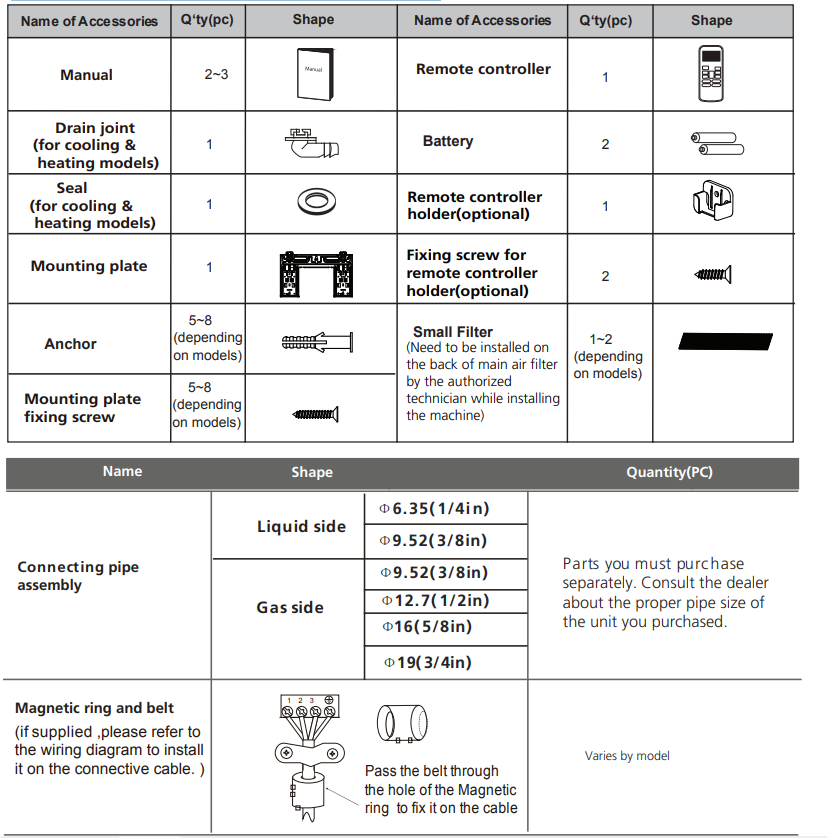

Accessories

The air conditioning system comes with the following accessories. Use all of the installation parts and accessories to install the air conditioner. Improper installation may result in water leakage, electrical shock and fire, or cause the equipment to fail. The items are not included with the air conditioner must be purchased separately

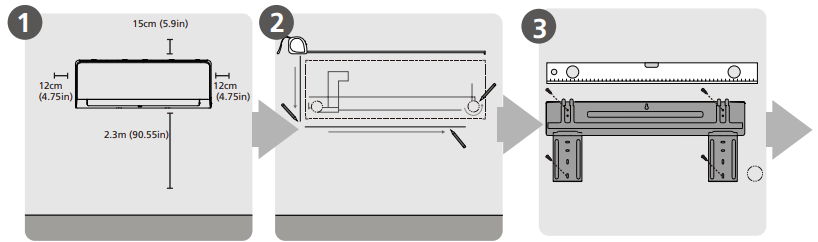

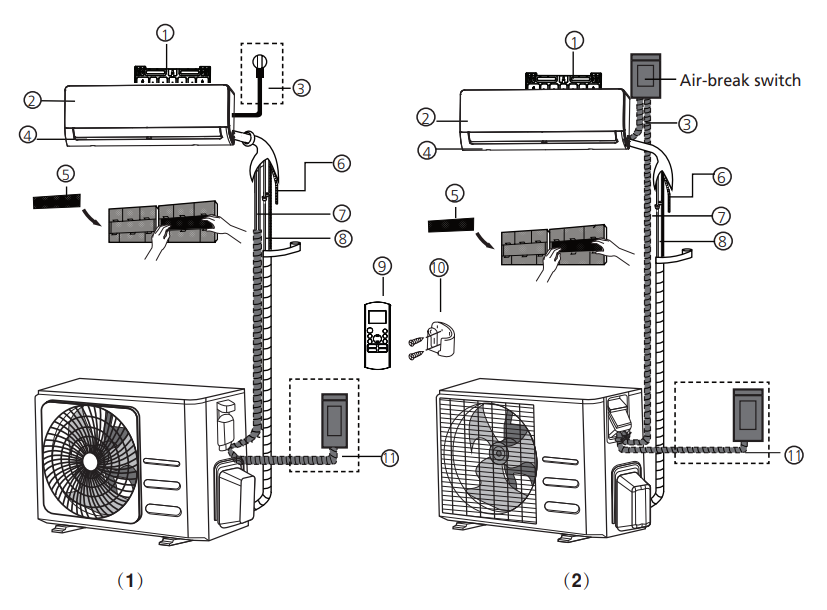

Installation Summary - Indoor Unit

1. Select Installation Location

2. Determine Wall Hole Position

3. Attach Mounting Plate

4. Drill Wall Hole

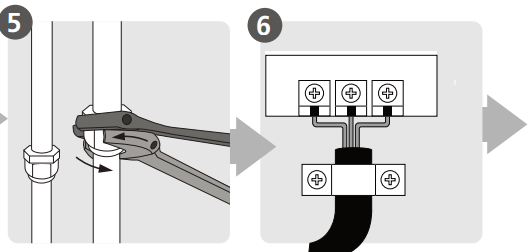

5. Connect Piping

6. Connect Wiring (not applicable for some locations in North America )

7. Prepare Drain Hose

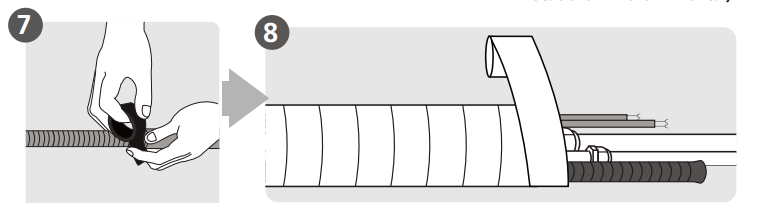

8. Wrap Piping and Cable (not applicable for some locations in North America )

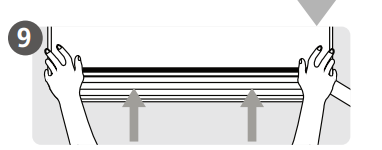

9. Mount Indoor Unit

Unit Parts: NOTE: The installation must be performed in accordance with the requirement of local and national standards. The installation may be slightly different in different areas.

- Wall Mounting Plate

- Front Panel

- Power Cable (Some Units)

- Louver

- Functional Filter (On Back of Main Filter - Some Units)

- Drainage Pipe

- Signal Cable

- Refrigerant Piping

- Remote Controller

- Remote controller Holder (Some Units)

- Outdoor Unit Power Cable (Some Units)

NOTE ON ILLUSTRATIONS: Illustrations in this manual are for explanatory purposes. The actual shape of your indoor unit may be slightly different. The actual shape shall prevail.

Indoor Unit Installation

1. Installation Instructions – Indoor unit

PRIOR TO INSTALLATION: Before installing the indoor unit, refer to the label on the product box to make sure that the model number of the indoor unit matches the model number of the outdoor unit.

Step 1: Select installation location Before installing the indoor unit, you must choose an appropriate location. The following are standards that will help you choose an appropriate location for the unit.

Proper installation locations meet the following standards:

- Good air circulation

- Convenient drainage

- Noise from the unit will not disturb other people

- Firm and solid—the location will not vibrate

- Strong enough to support the weight of the unit

- A location at least one meter from all other electrical devices (e.g., TV, radio, computer)

DO NOT install unit in the following locations:

- Near any source of heat, steam, or combustible gas

- Near flammable items such as curtains or clothing

- Near any obstacle that might block air circulation

- Near the doorway

- In a location subject to direct sunlight

NOTE ABOUT WALL HOLE: If there is no fixed refrigerant piping: While choosing a location, be aware that you should leave ample room for a wall hole (see Drill wall hole for connective piping step) for the signal cable and refrigerant piping that connect the indoor and outdoor units. The default position for all piping is the right side of the indoor unit (while facing the unit). However, the unit can accommodate piping to both the left and right.

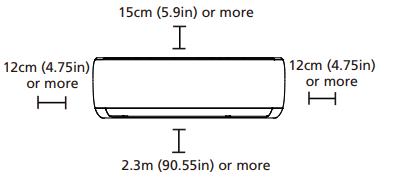

Refer to the following diagram to ensure proper distance from walls and ceiling:

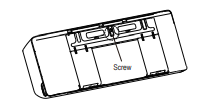

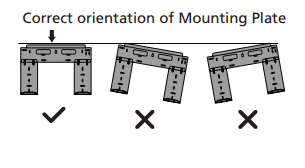

Step 2: Attach mounting plate to wall

The mounting plate is the device on which you will mount the indoor unit.

- Remove the screw that attaches the mounting plate to the back of the indoor unit.

- Secure the mounting plate to the wall with the screws provided. Make sure that mounting plate is flat against the wall.

NOTE FOR CONCRETE OR BRICK WALLS: If the wall is made of brick, concrete, or similar material, drill 5mm-diameter (0.2in-diameter) holes in the wall and insert the sleeve anchors provided. Then secure the mounting plate to the wall by tightening the screws directly into the clip anchors.

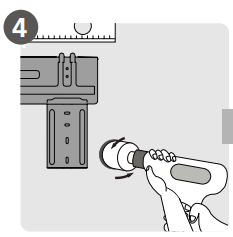

Step 3: Drill wall hole for connective piping

- Determine the location of the wall hole based on the position of the mounting plate. Refer to Mounting Plate Dimensions.

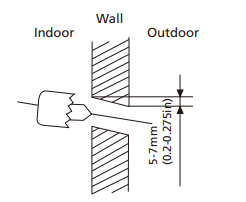

- Using a 65mm (2.5in) or 90mm(3.54in) (depending on models )core drill, drill a hole in the wall. Make sure that the hole is drilled at a slight downward angle, so that the outdoor end of the hole is lower than the indoor end by about 5mm to 7mm (0.2-0.275in). This will ensure proper water drainage.

- Place the protective wall cuff in the hole. This protects the edges of the hole and will help seal it when you finish the installation process.

CAUTION: When drilling the wall hole, make sure to avoid wires, plumbing, and other sensitive components.

MOUNTING PLATE DIMENSIONS Different models have different mounting plates. For the different customization requirements, the shape of the mounting plate may be slightly different. But the installation dimensions are the same for the same size of indoor unit. See Type A and Type B for example:

NOTE: When the gas side connective pipe is  16mm(5/8in) or more, the wall hole should be 90mm(3.54in).

16mm(5/8in) or more, the wall hole should be 90mm(3.54in).

Step 4: Prepare refrigerant piping The refrigerant piping is inside an insulating sleeve attached to the back of the unit. You must prepare the piping before passing it through the hole in the wall.

- Based on the position of the wall hole relative to the mounting plate, choose the side from which the piping will exit the unit.

- If the wall hole is behind the unit, keep the knock-out panel in place. If the wall hole is to the side of the indoor unit, remove the plastic knock-out panel from that side of the unit. This will create a slot through which your piping can exit the unit. Use needle nose pliers if the plastic panel is too difficult to remove by hand.

- If existing connective piping is already embedded in the wall, proceed directly to the Connect Drain Hose step. If there is no embedded piping, connect the indoor unit’s refrigerant piping to the connective piping that will join the indoor and outdoor units. Refer to the Refrigerant Piping Connection section of this manual for detailed instructions.

NOTE ON PIPING ANGLE: Refrigerant piping can exit the indoor unit from four different angles:Left-hand side,Right-hand side, Left rear, Right rear

CAUTION: Be extremely careful not to dent or damage the piping while bending them away from the unit. Any dents in the piping will affect the unit’s performance.

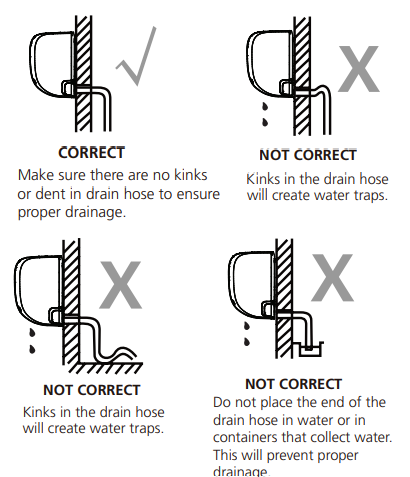

Step 5:Connect drain hose By default, the drain hose is attached to the lefthand side of unit (when you’re facing the back of the unit). However, it can also be attached to the right-hand side. To ensure proper drainage, attach the drain hose on the same side that your refrigerant piping exits the unit. Attach drain hose extension (purchased separately) to the end of drain hose.

- Wrap the connection point firmly with Teflon tape to ensure a good seal and to prevent leaks

- For the portion of the drain hose that will remain indoors, wrap it with foam pipe insulation to prevent condensation.

- Remove the air filter and pour a small amount of water into the drain pan to make sure that water flows from the unit smoothly.

NOTE ON DRAIN HOSE PLACEMENT: Make sure to arrange the drain hose according to the following figures.

PLUG THE UNUSED DRAIN HOLE: To prevent unwanted leaks you must plug the unused drain hole with the rubber plug provided.

BEFORE PERFORMING ANY ELECTRICAL WORK, READ THESE REGULATIONS

- All wiring must comply with local and national electrical codes, regulations and must be installed by a licensed electrician.

- All electrical connections must be made according to the Electrical Connection Diagram located on the panels of the indoor and outdoor units.

- If there is a serious safety issue with the power supply, stop work immediately. Explain your reasoning to the client, and refuse to install the unit until the safety issue is properly resolved.

- Power voltage should be within 90-110% of rated voltage. Insufficient power supply can cause malfunction, electrical shock, or fire.

- If connecting power to fixed wiring, a surge protector and main power switch should be installed.

- If connecting power to fixed wiring, a switch or circuit breaker that disconnects all poles and has a contact separation of at least 1/8in (3mm) must be incorporated in the fixed wiring. The qualified technician must use an approved circuit breaker or switch.

- Only connect the unit to an individual branch circuit outlet. Do not connect another appliance to that outlet.

- Make sure to properly ground the air conditioner.

- Every wire must be firmly connected. Loose wiring can cause the terminal to overheat, resulting in product malfunction and possible fire.

- Do not let wires touch or rest against refrigerant tubing, the compressor, or any moving parts within the unit.

- If the unit has an auxiliary electric heater, it must be installed at least 1 meter (40in) away from any combustible materials.

- To avoid getting an electric shock, never touch the electrical components soon after the power supply has been turned off. After turning off the power, always wait 10 minutes or more before you touch the electrical components

WARNING: BEFORE PERFORMING ANY ELECTRICAL OR WIRING WORK, TURN OFF THE MAIN POWER TO THE SYSTEM

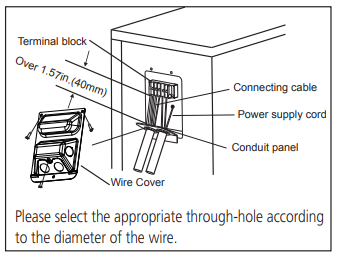

Step 6: Connect signal and power cables: The signal cable enables communication between the indoor and outdoor units. You must first choose the right cable size before preparing it for connection. Cable Types

- Indoor Power Cable (if applicable): H05VV-F or H05V2V2-F

- Outdoor Power Cable: H07RN-F or H05RN-F

- Signal Cable: H07RN-F

NOTE: In North America, choose the cable type according to the local electrical codes and regulations

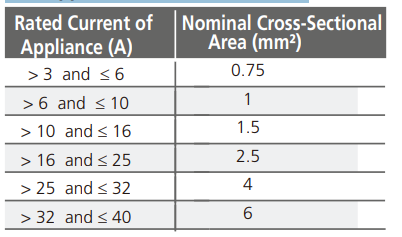

Minimum Cross-Sectional Area of Power and Signal Cables (For reference) (Not applicable for North America)

CHOOSE THE RIGHT CABLE SIZE

- The size of the power supply cable, signal cable, fuse, and switch needed is determined by the maximum current of the unit. The maximum current is indicated on the nameplate located on the side panel of the unit.

- NOTE: In North America, please choose the right cable size according to the Minimum Circuit Ampacity indicated on the nameplate of the unit

WARNING: ALL WIRING MUST BE PERFORMED STRICTLY IN ACCORDANCE WITH THE WIRING DIAGRAM LOCATED ON THE BACK OF THE INDOOR UNIT S FRONT PANEL .

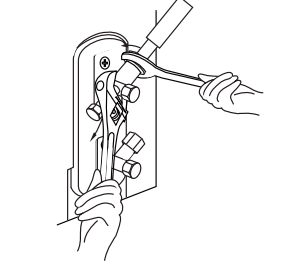

- Open front panel of the indoor unit.

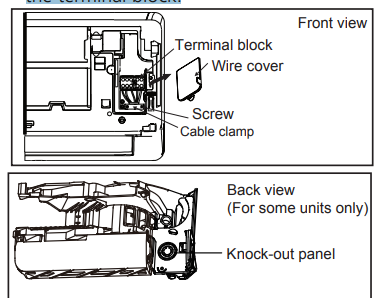

- Using a screwdriver, open the wire box cover on the right side of the unit. This will reveal the terminal block.

. NOTE: For the units with conduit tube to connect the cable, remove the big plastic konck-out panel to create a slot through which the conduit tube can be installed. For the units with five-core cable, remove the middle small plactic knock-out panel to create a slot through which the cable can exit. Use needle nose pliers if the plastic panel is too difficult to remove by hand.

. NOTE: For the units with conduit tube to connect the cable, remove the big plastic konck-out panel to create a slot through which the conduit tube can be installed. For the units with five-core cable, remove the middle small plactic knock-out panel to create a slot through which the cable can exit. Use needle nose pliers if the plastic panel is too difficult to remove by hand. - Unscrew the cable clamp below the terminal block and place it to the side.

- Facing the back of the unit, remove the plastic panel on the bottom left-hand side.

- Feed the signal wire through this slot, from the back of the unit to the front.

- Facing the front of the unit, connect the wire according to the indoor unit’s wiring diagram, connect the u-lug and firmly screw each wire to its corresponding terminal.

- After checking to make sure every connection is secure, use the cable clamp to fasten the signal cable to the unit. Screw the cable clamp down tightly.

- Replace the wire cover on the front of the unit, and the plastic panel on the back.

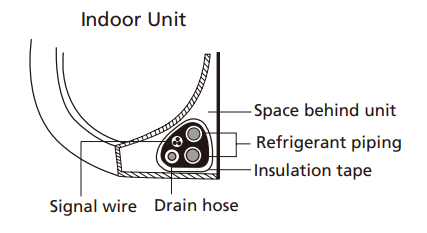

Step 7: Wrappiping and cables: Before passing the piping, drain hose, and the signal cable through the wall hole, you must bundle them together to save space, protect them, and insulate them(Not applicable in North America)

- Bundle the drain hose, refrigerant pipes, and signal cable as shown below:

. DRAIN HOSE MUST BE ON BOTTOM: Make sure that the drain hose is at the bottom of the bundle. Putting the drain hose at the top of the bundle can cause the drain pan to overflow, which can lead to fire or water damage. DO NOT INTERTWINE SIGNAL CABLE WITH OTHER WIRES: While bundling these items together, do not intertwine or cross the signal cable with any other wiring.

. DRAIN HOSE MUST BE ON BOTTOM: Make sure that the drain hose is at the bottom of the bundle. Putting the drain hose at the top of the bundle can cause the drain pan to overflow, which can lead to fire or water damage. DO NOT INTERTWINE SIGNAL CABLE WITH OTHER WIRES: While bundling these items together, do not intertwine or cross the signal cable with any other wiring. - Using adhesive vinyl tape, attach the drain hose to the underside of the refrigerant pipes.

- Using insulation tape, wrap the signal wire, refrigerant pipes, and drain hose tightly together. Double-check that all items are bundled.

DO NOT WRAP ENDS OF PIPING: When wrapping the bundle, keep the ends of the piping unwrapped. You need to access them to test for leaks at the end of the installation process (refer to Electrical Checks and Leak Checks section of this manual).

Step 8: Mount indoor unit

If you installed new connective piping to the outdoor unit, do the following:

- If you have already passed the refrigerant piping through the hole in the wall, proceed to Step 4.

- Otherwise, double-check that the ends of the refrigerant pipes are sealed to prevent dirt or foreign materials from entering the pipes.

- Slowly pass the wrapped bundle of refrigerant pipes, drain hose, and signal wire through the hole in the wall.

- Hook the top of the indoor unit on the upper hook of the mounting plate.

- Check that unit is hooked firmly on mounting by applying slight pressure to the left and right-hand sides of the unit. The unit should not jiggle or shift.

- Using even pressure, push down on the bottom half of the unit. Keep pushing down until the unit snaps onto the hooks along the bottom of the mounting plate.

- Again, check that the unit is firmly mounted by applying slight pressure to the left and the right-hand sides of the unit.

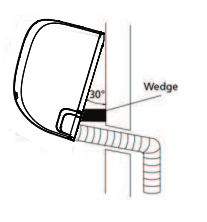

If refrigerant piping is already embedded in the wall, do the following:

- Hook the top of the indoor unit on the upper hook of the mounting plate.

- Use a bracket or wedge to prop up the unit, giving you enough room to connect the refrigerant piping, signal cable, and drain hose.

- Connect drain hose and refrigerant piping (refer to Refrigerant Piping Connection section of this manual for instructions).

- Keep pipe connection point exposed to perform the leak test (refer to Electrical Checks and Leak Checks section of this manual).

- After the leak test, wrap the connection point with insulation tape.

- Remove the bracket or wedge that is propping up the unit.

- Using even pressure, push down on the bottom half of the unit. Keep pushing down until the unit snaps onto the hooks along the bottom of the mounting plate.

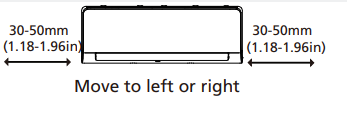

UNIT IS ADJUSTABLE: Keep in mind that the hooks on the mounting plate are smaller than the holes on the back of the unit. If you find that you don’t have ample room to connect embedded pipes to the indoor unit, the unit can be adjusted left or right by about 30-50mm (1.18-1.96in), depending on the model.

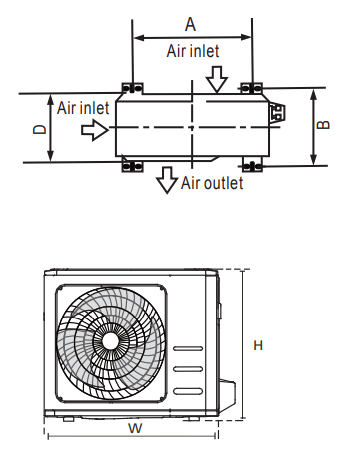

Outdoor Unit Installation

Install the unit by following local codes and regulations , there may be differ slightly between different regions.

Installation Instructions – Outdoor unit

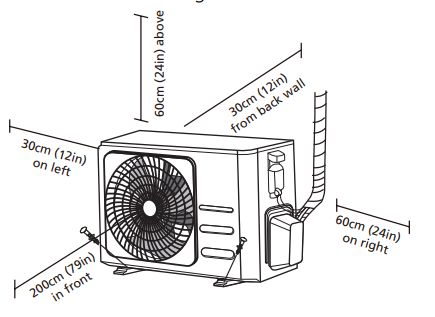

Step 1: Select installation location: Before installing the outdoor unit, you must choose an appropriate location. The following are standards that will help you choose an appropriate location for the unit. Proper installation locations meet the following standards:

- Meets all spatial requirements shown in Installation Space Requirements above.

- Good air circulation and ventilation

- Firm and solid—the location can support the unit and will not vibrate

- Noise from the unit will not disturb others

- Protected from prolonged periods of direct sunlight or rain

- Where snowfall is anticipated, raise the unit above the base pad to prevent ice buildup and coil damage. Mount the unit high enough to be above the average accumulated area snowfall. The minimum height must be 18 inches

DO NOT install unit in the following locations:

- Near an obstacle that will block air inlets and outlets

- Near a public street, crowded areas, or where noise from the unit will disturb others

- Near animals or plants that will be harmed by hot air discharge

- Near any source of combustible gas

- In a location that is exposed to large amounts of dust In a location exposed to a excessive amounts of salty air

SPECIAL CONSIDERATIONS FOR EXTREME WEATHER

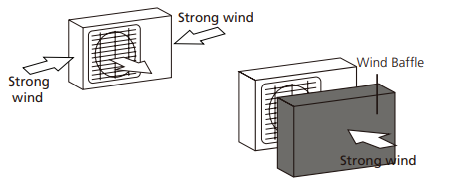

If the unit is exposed to heavy wind: Install unit so that air outlet fan is at a 90° angle to the direction of the wind. If needed, build a barrier in front of the unit to protect it from extremely heavy winds. See Figures below.

If the unit is frequently exposed to heavy rain or snow: Build a shelter above the unit to protect it from the rain or snow. Be careful not to obstruct air flow around the unit.

If the unit is frequently exposed to salty air (seaside): Use outdoor unit that is specially designed to resist corrosion.

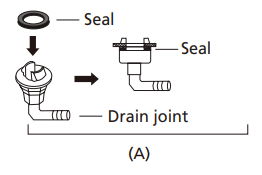

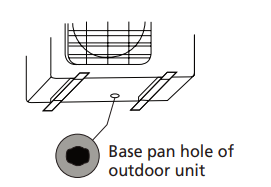

Step 2: Install drain joint(Heat pump unit only): Before bolting the outdoor unit in place, you must install the drain joint at the bottom of the unit. Note that there are two different types of drain joints depending on the type of outdoor unit.

If the drain joint comes with a rubber seal, do the following:

- Fit the rubber seal on the end of the drain joint that will connect to the outdoor unit.

- Insert the drain joint into the hole in the base pan of the unit.

- Rotate the drain joint 90° until it clicks in place facing the front of the unit.

- Connect a drain hose extension (not included) to the drain joint to redirect water from the unit during heating mode.

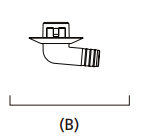

If the drain joint doesn’t come with a rubber seal, do the following:

- Insert the drain joint into the hole in the base pan of the unit. The drain joint will click in place.

- Connect a drain hose extension (not included) to the drain joint to redirect water from the unit during heating mode.

IN COLD CLIMATES: In cold climates, make sure that the drain hose is as vertical as possible to ensure swift water drainage. If water drains too slowly, it can freeze in the hose and flood the unit.

Step 3: Anchor outdoor unit

The outdoor unit can be anchored to the ground or to a wall-mounted bracket with bolt(M10). Prepare the installation base of the unit according to the dimensions below.

UNIT MOUNTING DIMENSIONS: The following is a list of different outdoor unit sizes and the distance between their mounting feet. Prepare the installation base of the unit according to the dimensions below.

If you will install the unit on the ground or on a concrete mounting platform, do the following:

- Mark the positions for four expansion bolts based on dimensions chart.

- Pre-drill holes for expansion bolts.

- Place a nut on the end of each expansion bolt.

- Hammer expansion bolts into the pre-drilled holes.

- Remove the nuts from expansion bolts, and place outdoor unit on bolts.

- Put washer on each expansion bolt, then replace the nuts.

- Using a wrench, tighten each nut until snug.

If you will install the unit on a wall-mounted bracket , do the following: CAUTION: Make sure that the wall is made of solid brick, concrete, or of similarly strong material. The wall must be able to support at least four times the weight of the unit.

- Mark the position of bracket holes based on dimensions chart.

- Pre-drill the holes for the expansion bolts.

- Place a washer and nut on the end of each expansion bolt.

- Thread expansion bolts through holes in mounting brackets, put mounting brackets in position, and hammer expansion bolts into the wall.

- Check that the mounting brackets are level.

- . Carefully lift unit and place its mounting feet on brackets.

- Bolt the unit firmly to the brackets.

- If allowed, install the unit with rubber gaskets to reduce vibrations and noise.

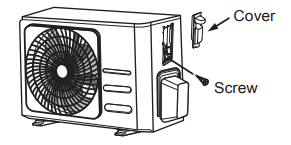

Step 4: Connect signal and power cables: The outside unit’s terminal block is protected by an electrical wiring cover on the side of the unit. A comprehensive wiring diagram is printed on the inside of the wiring cover. WARNING: BEFORE PERFORMING ANY ELECTRICAL OR WIRING WORK, TURN OFF THE MAIN POWER TO THE SYSTEM.

1. Prepare the cable for connection: USE THE RIGHT CABLE. Please choose the right cable refer to “ Cable types”. CHOOSE THE RIGHT CABLE SIZE: The size of the power supply cable, signal cable, fuse, and switch needed is determined by the maximum current of the unit. The maximum current is indicated on the nameplate located on the side panel of the unit. NOTE: In North America, please choose the right cable size according to the Minimum Circuit Ampacity indicated on the nameplate of the unit.

- Using wire strippers, strip the rubber jacket from both ends of cable to reveal about 40mm (1.57in) of the wires inside.

- Strip the insulation from the ends of the wires.

- Using a wire crimper, crimp u-lugs on the ends of the wires

PAY ATTENTION TO LIVE WIRE: While crimping wires, make sure you clearly distinguish the Live (“L”) Wire from other wires.

WARNING: ALL WIRING WORK MUST BE PERFORMED STRICTLY IN ACCORDANCE WITH THE WIRING DIAGRAM LOCATED INSIDE OF WIRE COVER OF THE OUTDOOR UNIT .

2. Unscrew the electrical wiring cover and remove it.

3. Unscrew the cable clamp below the terminal block and place it to the side.

4. Connect the wire according to the wiring diagram, and firmly screw the u-lug of each wire to its corresponding terminal.

5. After checking to make sure every connection is secure, loop the wires around to prevent rain water from flowing into the terminal.

6. Using the cable clamp, fasten the cable to the unit. Screw the cable clamp down tightly.

7. Insulate unused wires with PVC electrical tape. Arrange them so that they do not touch any electrical or metal parts.

8. Replace the wire cover on the side of the unit, and screw it in place.

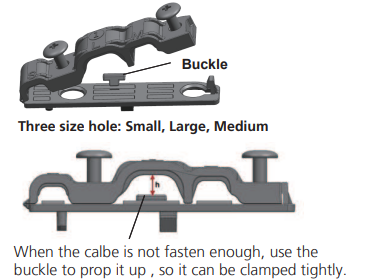

NOTE: If the cable clamp looks like the following, please select the appropriate through-hole according to the diameter of the wire.

In North America

- Remove the wire cover from the unit by loosening the 3 screws.

- Dismount caps on the conduit panel.

- Temperarily mount the conduit tubes(not included) on the conduit panel.

- Properly connect both the power supply and low voltage lines to the corresponding terminals on the terminal block.

- Ground the unit in accordance with local codes.

- Be sure to size each wire allowing several inches longer than the required length for wiring.

- Use lock nuts to secure the conduit tubes.

Refrigerant Piping Connection

When connecting refrigerant piping, do not let substances or gases other than the specified refrigerant enter the unit. The presence of other gases or substances will lower the unit’s capacity, and can cause abnormally high pressure in the refrigeration cycle. This can cause explosion and injury

Note on Pipe Length

- The length of refrigerant piping will affect the performance and energy efficiency of the unit. Nominal efficiency is tested on units with a pipe length of 5 meters (16.5ft)( In North America, the standard pipe length is 7.5m (25’)). A minimum pipe run of 3 metres is required to minimise vibration & excessive noise. In special tropical area, for the R290 refrigerant models, no refrigerant can be added and the maximum length of refrigerant pipe should not exceed 10 meters(32.8ft).

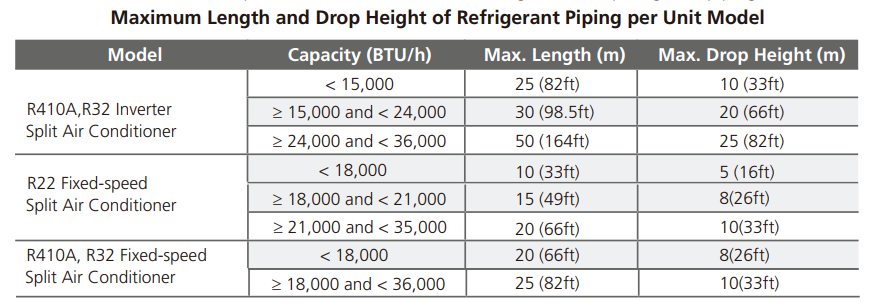

- Refer to the table below for specifications on the maximum length and drop height of piping.

Connection Instructions – Refrigerant Piping

Step 1: Cut pipes: When preparing refrigerant pipes, take extra care to cut and flare them properly. This will ensure efficient operation and minimize the need for future maintenance.

- Measure the distance between the indoor and outdoor units.

- Using a pipe cutter, cut the pipe a little longer than the measured distance.

- Make sure that the pipe is cut at a perfect 90° angle.

DO NOT DEFORM PIPE WHILE CUTTING: Be extra careful not to damage, dent, or deform the pipe while cutting. This will drastically reduce the heating efficiency of the unit.

Step 2: Remove burrs: Burrs can affect the air-tight seal of refrigerant piping connection. They must be completely removed.

- Hold the pipe at a downward angle to prevent burrs from falling into the pipe.

- Using a reamer or deburring tool, remove all burrs from the cut section of the pipe.

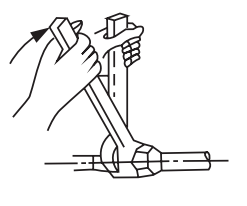

Step 3: Flare pipe ends Proper flaring is essential to achieve an airtight seal.

- After removing burrs from cut pipe, seal the ends with PVC tape to prevent foreign materials from entering the pipe.

- Sheath the pipe with insulating material.

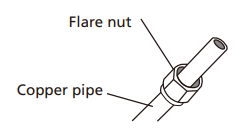

- Place flare nuts on both ends of pipe. Make sure they are facing in the right direction, because you can’t put them on or change their direction after flaring.

- Remove PVC tape from ends of pipe when ready to perform flaring work.

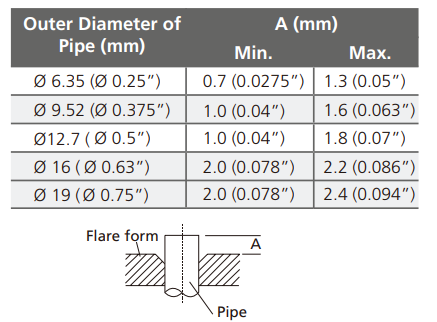

- Clamp flare form on the end of the pipe. The end of the pipe must extend beyond the edge of the flare form in accordance with the dimensions shown in the table below.

PIPING EXTENSION BEYOND FLARE FORM

PIPING EXTENSION BEYOND FLARE FORM

- Place flaring tool onto the form.

- Turn the handle of the flaring tool clockwise until the pipe is fully flared.

- Remove the flaring tool and flare form, then inspect the end of the pipe for cracks and even flaring.

Step 4: Connect pipes: When connecting refrigerant pipes, be careful not to use excessive torque or to deform the piping in any way. You should first connect the low-pressure pipe, then the high-pressure pipe.

MINIMUM BEND RADIUS: When bending connective refrigerant piping, the minimum bending radius is 10cm.

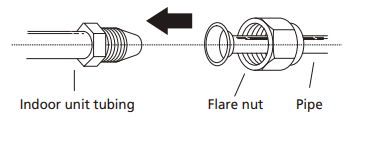

Instructions for Connecting Piping to Indoor Unit

- Align the center of the two pipes that you will connect.

- Tighten the flare nut as tightly as possible by hand.

- Using a spanner, grip the nut on the unit tubing.

- While firmly gripping the nut on the unit tubing, use a torque wrench to tighten the flare nut according to the torque values in the Torque Requirements table below. Loosen the flaring nut slightly, then tighten again.

TORQUE REQUIREMENTS

DO NOT USE EXCESSIVE TORQUE: Excessive force can break the nut or damage the refrigerant piping. You must not exceed torque requirements shown in the table above.

Instructions for Connecting Piping to Outdoor Unit

- Unscrew the cover from the packed valve on the side of the outdoor unit.

- Remove protective caps from ends of valves.

- Align flared pipe end with each valve, and tighten the flare nut as tightly as possible by hand.

- Using a spanner, grip the body of the valve. Do not grip the nut that seals the service valve.

- While firmly gripping the body of the valve, use a torque wrench to tighten the flare nut according to the correct torque values.

- Loosen the flaring nut slightly, then tighten again.

- Repeat Steps 3 to 6 for the remaining pipe.

USE SPANNER TO GRIP MAIN BODY OF VALVE: Torque from tightening the flare nut can snap off other parts of valve.

Air Evacuation

Preparations and Precautions

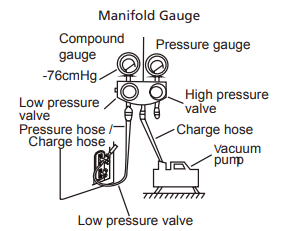

- Air and foreign matter in the refrigerant circuit can cause abnormal rises in pressure, which can damage the air conditioner, reduce its efficiency, and cause injury. Use a vacuum pump and manifold gauge to evacuate the refrigerant circuit, removing any non-condensable gas and moisture from the system.

- Evacuation should be performed upon initial installation and when unit is relocated.

BEFORE PERFORMING EVACUATION

- Check to make sure the connective pipes between the indoor and outdoor units are connected properly .

- Check to make sure all wiring is connected properly.

Evacuation Instructions

- Connect the charge hose of the manifold gauge to service port on the outdoor unit’s low pressure valve.

- Connect another charge hose from the manifold gauge to the vacuum pump.

- Open the Low Pressure side of the manifold gauge. Keep the High Pressure side closed.

- Turn on the vacuum pump to evacuate the system.

- Run the vacuum for at least 15 minutes, or until the Compound Meter reads -76cmHG (-10 Pa).

- Close the Low Pressure side of the manifold gauge, and turn off the vacuum pump.

- Wait for 5 minutes, then check that there has been no change in system pressure.

- If there is a change in system pressure, refer to Gas Leak Check section for information on how to check for leaks. If there is no change in system pressure, unscrew the cap

- from the packed valve (high pressure valve). Insert hexagonal wrench into the packed valve (high pressure valve) and open the valve by turning the wrench in a 1/4 counterclockwise turn. Listen for gas to exit the system, then close the valve after 5 seconds.

- Watch the Pressure Gauge for one minute to make sure that there is no change in pressure. The Pressure Gauge should read slightly higher than atmospheric pressure.

- Remove the charge hose from the service port.

- Using hexagonal wrench, fully open both the high pressure and low pressure valves.

- Tighten valve caps on all three valves (service port, high pressure, low pressure) by hand. You may tighten it further using a torque wrench if needed.

OPEN VALVE STEMS GENTLY: When opening valve stems, turn the hexagonal wrench until it hits against the stopper. Do not try to force the valve to open further.

Note on Adding Refrigerant: Some systems require additional charging depending on pipe lengths. The standard pipe length varies according to local regulations. For example, in North America, the standard pipe length is 7.5m (25’). In other areas, the standard pipe length is 5m (16‘). The refrigerant should be charged from the service port on the outdoor unit’s low pressure valve. The additional refrigerant to be charged can be calculated using the following formula:

ADDITIONAL REFRIGERANT PER PIPE LENGTH

For R290 refrigerant unit, the total amount of refrigerant to be charged is no more than: 387g(9000Btu/h and 12000Btu/h and 18000Btu/h and <=24000Btu/h).

CAUTION: DO NOT mix refrigerant types

Electrical and Gas Leak Checks

Before Test Run: Only perform test run after you have completed the following steps:

- Electrical Safety Checks – Confirm that the unit’s electrical system is safe and operating properly

- Gas Leak Checks – Check all flare nut connections and confirm that the system is not leaking

- Confirm that gas and liquid (high and low pressure) valves are fully open

Electrical Safety Checks

- After installation, confirm that all electrical wiring is installed in accordance with local and national regulations, and according to the Installation Manual.

BEFORE TEST RUN - Check Grounding Work

- Measure grounding resistance by visual detection and with grounding resistance tester. Grounding resistance must be less than 0.1Ω.

- Note: This may not be required for some locations in North America.

DURING TEST RUN

Check for Electrical Leakage

- During the Test Run, use an electroprobe and multimeter to perform a comprehensive electrical leakage test.

- If electrical leakage is detected, turn off the unit immediately and call a licensed electrician to find and resolve the cause of the leakage.

- Note: This may not be required for some locations in North America.

WARNING – RISK OF ELECTRIC SHOCK ALL WIRING MUST COMPLY WITH LOCAL AND NATIONAL ELECTRICAL CODES, AND MUST BE INSTALLED BY A LICENSED ELECTRICIAN.

Gas Leak Checks

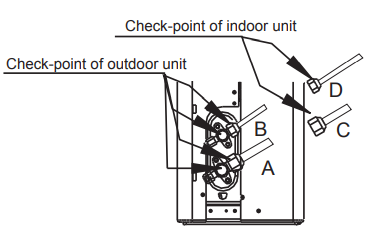

- There are two different methods to check for gas leaks.

- Soap and Water Method: Using a soft brush, apply soapy water or liquid detergent to all pipe connection points on the indoor unit and outdoor unit. The presence of bubbles indicates a leak.

- Leak Detector Method: If using leak detector, refer to the device’s operation manual for proper usage instructions.

AFTER PERFORMING GAS LEAK CHECKS

- After confirming that the all pipe connection points DO NOT leak, replace the valve cover on the outside unit.

A: Low pressure stop valve

B: High pressure stop valve

C& D: Indoor unit flare nuts

Test Run

Test Run Instructions - You should perform the Test Run for at least 30 minutes.

- Connect power to the unit.

- Press the ON/OFF button on the remote controller to turn it on.

- Press the MODE button to scroll through the following functions, one at a time: COOL – Select lowest possible temperature; HEAT – Select highest possible temperature

- Let each function run for 5 minutes, and perform the following checks:

DOUBLE-CHECK PIPE CONNECTIONS: During operation, the pressure of the refrigerant circuit will increase. This may reveal leaks that were not present during your initial leak check. Take time during the Test Run to double-check that all refrigerant pipe connection points do not have leaks. Refer to Gas Leak Check section for instructions.

DOUBLE-CHECK PIPE CONNECTIONS: During operation, the pressure of the refrigerant circuit will increase. This may reveal leaks that were not present during your initial leak check. Take time during the Test Run to double-check that all refrigerant pipe connection points do not have leaks. Refer to Gas Leak Check section for instructions. - After the Test Run is successfully completed, and you confirm that all checks points in List of Checks to Perform have PASSED, do the following: Using remote control, return unit to normal operating temperature. Using insulation tape, wrap the indoor refrigerant pipe connections that you left uncovered during the indoor unit installation process.

IF AMBIENT TEMPERATURE IS BELOW 17°C (62°F): You can’t use the remote controller to turn on the COOL function when the ambient temperature is below 17°C. In this instance, you can use the MANUAL CONTROL button to test the COOL function.

- Lift the front panel of the indoor unit, and raise it until it clicks in place.

- The MANUAL CONTROL button is located on the right-hand side of the unit. Press it 2 times to select the COOL function.

- Perform Test Run as normal.

See other models: MSFAAU-12HRFN8-QRD6GW MB-M25 MRQ23P4AST MRT18S4AWW MRW14S1ABB