Loading ...

Loading ...

Loading ...

9

5) GAS CONNECTION

The gas connection is located in the rear and on

the right hand underside of these appliances:

90 mm (mod:

EMJGC60SX

),

80 mm (mod:

EMJGC900SX

),

30 mm (mod: EMJG30WSX).

There are two ways to carry out the connection to the

main gas line:

A. The hotplate can be connected with rigid pipe as

specified in AS/NZS 5601.

B. If installing with a hose assembly, install with a

hose assembly that complies with AS/ANZ 1869

(Australian Certified), 10 mm ID, class B or D, no

more than 1.2 m long and in accordance with

AS/NZS 5601. Ensure that the hose does not

contact the hot surfaces of the hotplate, oven,

dishwasher or any other appliance that may be

installed underneath or next to the hotplate. The

hose should not be subjected to abrasion, kinking

or permanent deformation and should be able to be

inspected along its entire length with the hotplate in

the installed position.

Unions compatible with the hose fittings must be

used and all connections tested for gas leaks.

The gas supply connection point must be

accessible with the appliance installed.

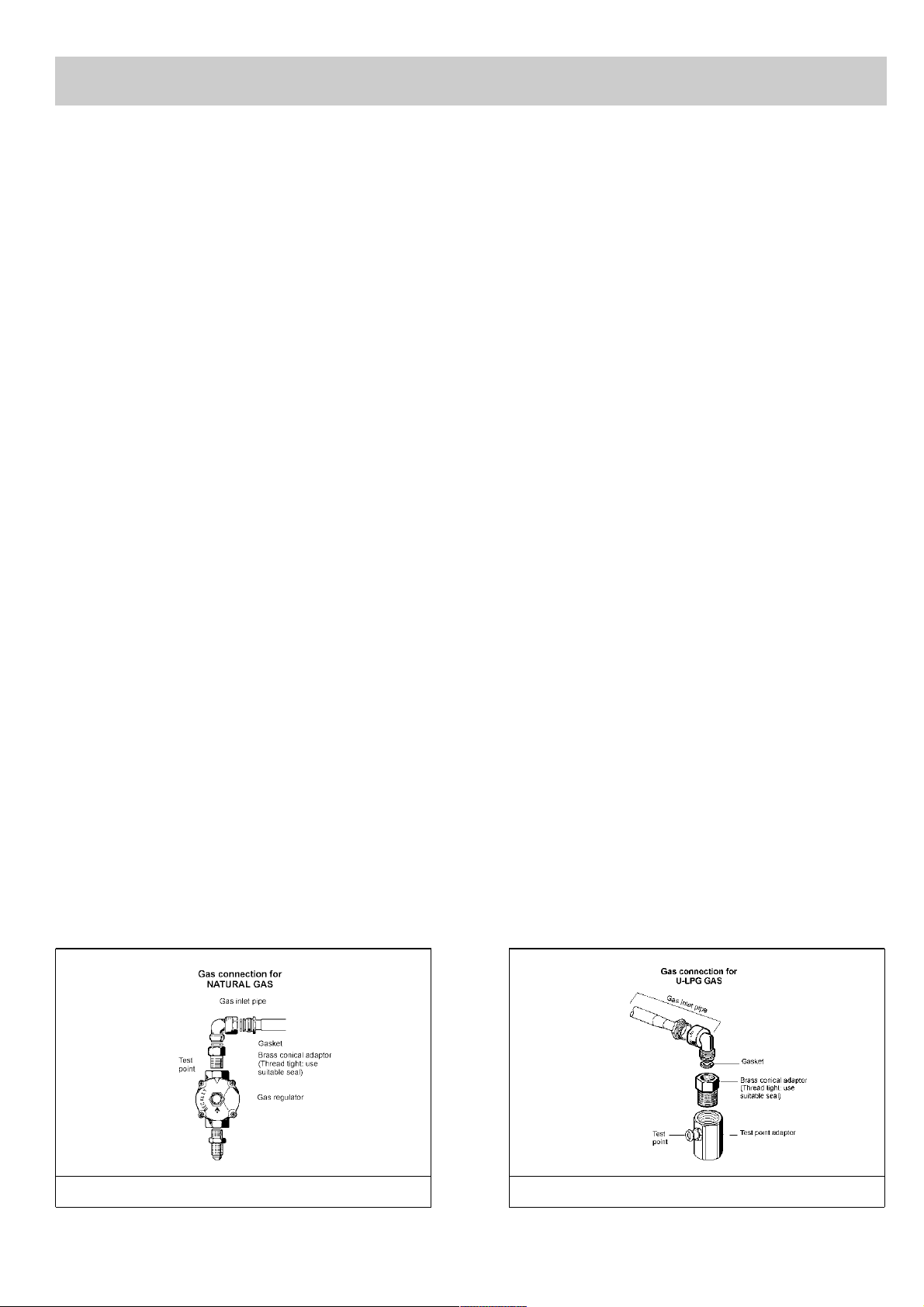

Natural Gas

Natural Gas installations require the connection of a

gas regulator at the appliance.

Assemble the regulator (noting the gas flow

direction) and transition piece, in accordance with

figure 10.

The transition piece on the supply side of the

regulator must be provided by the installer.

Liquified Petroleum Gas

In a U-LPG installation the gas regulation is made

at the gas cylinder and regulation at the appliance

is not required. To connect supply to the appliance

use transition pieces as shown in

figure 11/A. These pieces are supplied with the

appliance on purchase.

WARNING:

THE BURNER FLAME MUST BE ADJUSTED BY

THE INSTALLER.

FAULTY INSTALLATION WILL NOT BE

COVERED UNDER WARRANTY.

THE APPLIANCE IS FACTORY SET FOR NATURAL

GAS. THE TEST POINT PRESSURE SHOULD BE

ADJUSTED TO 1.00kPa WITH THE WOK BURNER

OPERATING AT MAXIMUM.

INSTALLATION

FIG. 11 FIG. 11/A

Loading ...

Loading ...

Loading ...