Loading ...

Loading ...

Loading ...

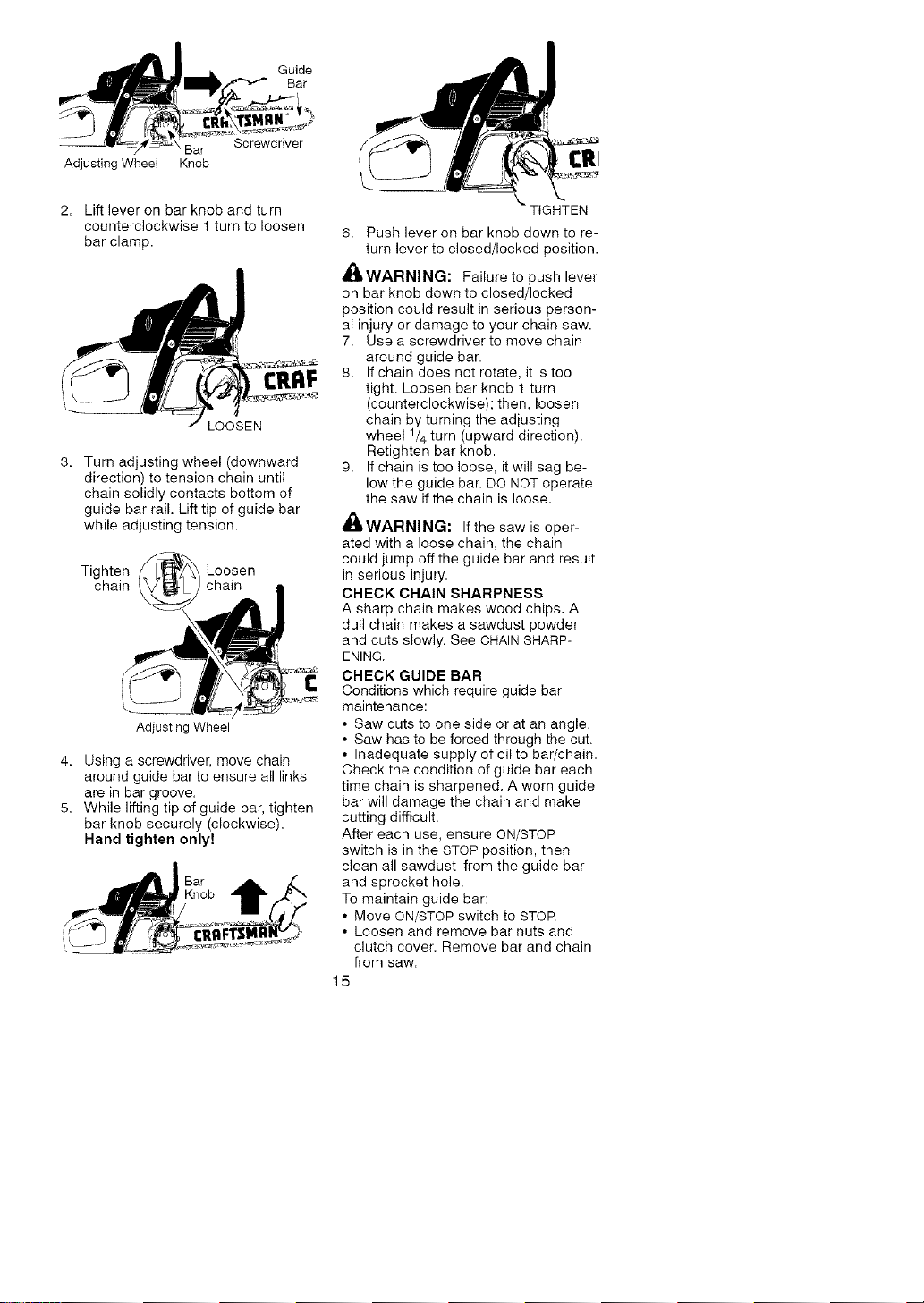

Adjusting Wheel Knob

2. Lift lever on bar knob and turn

counterclockwise 1 turn to loosen

bar clamp.

LOOSEN

3. Turn adjusting wheel (downward

direction) to tension chain until

chain solidly contacts bottom of

guide bar rail. Lift tip of guide bar

while adjusting tension.

Tighten Loosen

chain chain

Adjusting Wheel

4. Using a screwdriver, move chain

around guide bar to ensure all links

are in bar groove.

5. While lifting tip of guide bar, tighten

bar knob securely (clockwise).

Hand tighten only!

TIGHTEN

6. Push lever on bar knob down to re-

turn lever to closed/locked position.

_L, WARNING: Failure to push lever

on bar knob down to closed/locked

position could result in serious person-

al injury or damage to your chain saw.

7. Use a screwdriver to move chain

around guide bar.

8. If chain does not rotate, it is too

tight. Loosen bar knob 1 turn

(counterclockwise); then, loosen

chain by turning the adjusting

wheel 1/4 turn (upward direction).

Retighten bar knob.

9. If chain is too loose, it will sag be-

low the guide bar. DO NOT operate

the saw if the chain is loose.

,d_WARNING: If the saw is oper-

ated with a loose chain, the chain

could jump off the guide bar and result

in serious injury.

CHECK CHAIN SHARPNESS

A sharp chain makes wood chips. A

dull chain makes a sawdust powder

and cuts slowly. See CHAIN SHARP-

ENING,

CHECK GUIDE BAR

Conditions which require guide bar

maintenance:

• Saw cuts to one side or at an angle.

• Saw has to be forced through the cut.

• Inadequate supply of oil to bar/chain.

Check the condition of guide bar each

time chain is sharpened. A worn guide

bar will damage the chain and make

cutting difficult.

After each use, ensure ON/STOP

switch is in the STOP position, then

clean all sawdust from the guide bar

and sprocket hole.

To maintain guide bar:

• Move ON/STOP switch to STOP.

• Loosen and remove bar nuts and

clutch cover. Remove bar and chain

from saw.

15

Loading ...

Loading ...

Loading ...