Loading ...

Loading ...

Loading ...

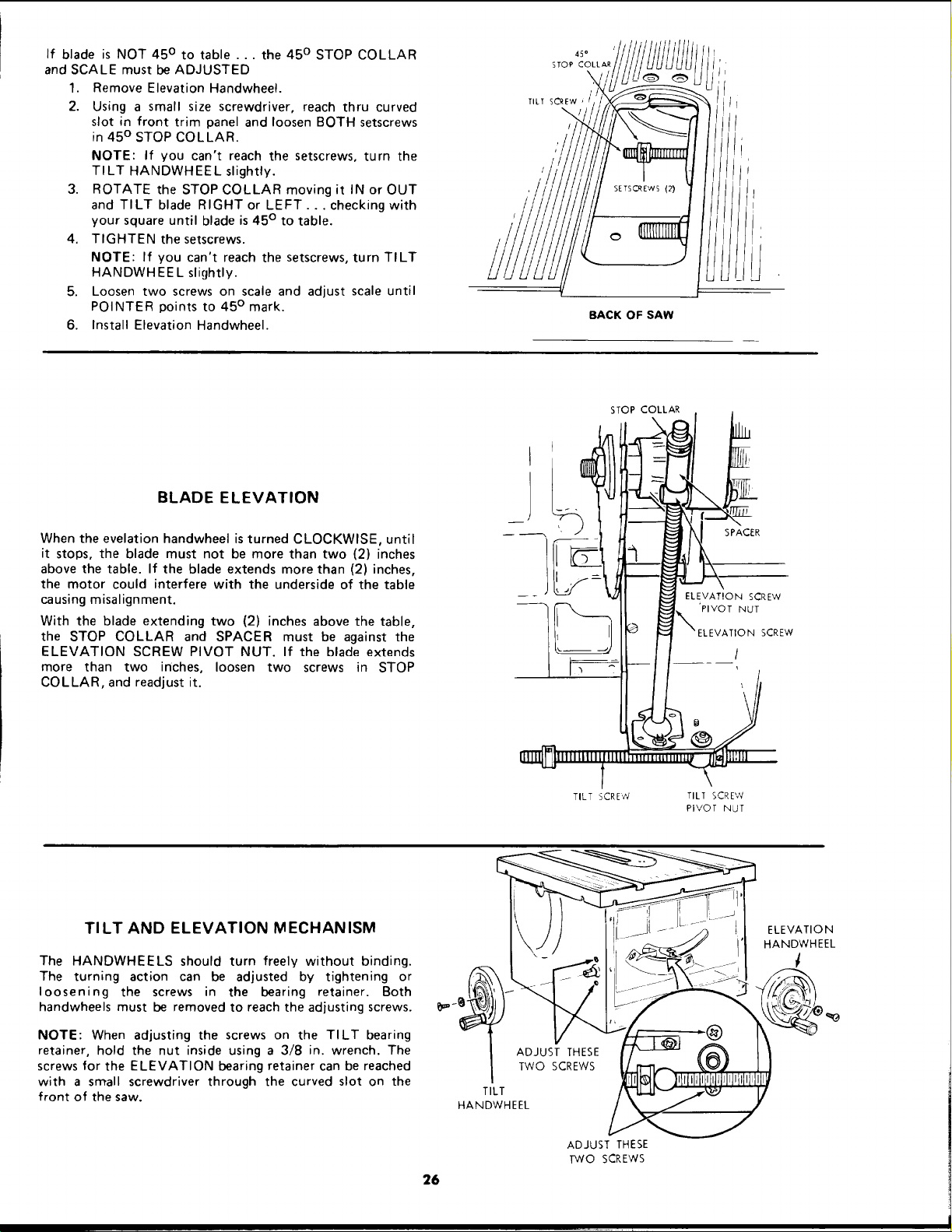

If blade is NOT 45 ° to table ... the 45 ° STOP COLLAR

and SCALE must be ADJUSTED

1. Remove Elevation Handwheel.

2. Using a small size screwdriver, reach thru curved

slot in front trim panel and loosen BOTH setscrews

in 45 ° STOP COLLAR.

NOTE: If you can't reach the setscrews, turn the

TILT HANDWHEEL slightly.

3. ROTATE the STOP COLLAR moving it IN or OUT

and TILT blade RIGHT or LEFT... checking with

your square until blade is 45 ° to table.

4. TIGHTEN the setscrews.

NOTE: If you can't reach the setscrews, turn TILT

HANDWHEEL slightly.

5. Loosen two screws on scale and adjust scale until

POINTER points to 45 ° mark.

6. Install Elevation Handwheel.

45°

STOP COLLAR

\

TILT SCREW '

BACK OF SAW

J

STOP COLLAR

BLADE ELEVATION

When the evelation handwheel is turned CLOCKWISE, until

it stops, the blade must not be more than two (2) inches

above the table. If the blade extends more than (2) inches,

the motor could interfere with the underside of the table

causing misalignment.

With the blade extending two (2) inches above the table,

the STOP COLLAR and SPACER must be against the

ELEVATION SCREW PIVOT NUT. If the blade extends

more than two inches, loosen two screws in STOP

COLLAR, and readjust it.

SPACER

ELEVATION SCREW

"PIVOT NUT

SCREW

TILT SCREvV

TILT SCREW

PIVOT NUT

TILT AND ELEVATION MECHANISM

The HANDWHEELS should turn freely without binding.

The turning action can be adjusted by tightening or

loosening the screws in the bearing retainer. Both

handwheels must be removed to reach the adjusting screws.

NOTE: When adjusting the screws on the TILT bearing

retainer, hold the nut inside using a 3/8 in. wrench. The

screws for the ELEVATION bearing retainer can be reached

with a small screwdriver through the curved slot on the

front of the saw.

ADJUST THESE

TWO SCREWS

TILT

HANDWHEEL

ELEVATION

HANDWHEEL

26

ADJUST THESE

1M/O SCREWS

Loading ...

Loading ...

Loading ...