Loading ...

Loading ...

Loading ...

It is extremelyimportantthat eachcuttingblade

edgebe groundequallyto maintainproperblade

balance.Anunbalancedbladewiltcauseexcessive

vibrationwhenrotatingat highspeeds,maycause

damageto thetractorandresultin personalinjury.

Thebladecanbetestedbybalancingiton ablade

balanceror roundshaftscrewdriver.Grindmetal

fromtheheavysideuntilitbalancesevenly.

Whenreplacingthe blade,be sureto installthe

bladewiththesideoftheblademarked"Bottom"(or

withapartnumberstampedinit)facingtheground

whenthemowerisintheoperatingposition.

IMPORTANT: Use a torque wrench to tighten the

blade spindle hex flange nut to between 70 foot-

pounds and 90 foot-pounds.

TIRES

The recommended operating tire pressure is

approximately 10 psi for the rear tires and 14 psi for

the front tires. Refer to the tire sidewall for exact tire

manufacturer's recommended psi. Do not

ovednflate. Uneven tire pressure could cause the

cutting deck to mow unevenly.

BATTERY

The battery is sealed and is maintenance-free. Acid

levels cannot be checked.

• Always keep the battery cables and terminals

clean and free of corrosive build-up.

• After cleaning the battery and terminals, apply

a light coat of petroleum jelly or grease to the

terminals and over the positive terminal boot.

• Always keep the boot positioned over the

positive terminal to prevent shorting.

IMPORTANT: If removing the battery for any

reason, disconnect the NEGATIVE (Black) wire from

it's terminal first, followed by the POSITIVE (Red)

wire. When re-installing the battery, always connect

the POSITIVE (Red) wire its terminal first, followed

by the NEGATIVE (Black) wire. Be certain that the

wires are connected to the correct terminals,

reversing them could change the polarity and cause

damage to your engine's alternating system.

Charging

If the unit has not been put into use for an extended

period of time, charge the battery with an

automotive-type 12-volt charger for a minimum of

one hour at six amps.

WARNING: Batteries give off an

explosive gas during and for some time

after charging. Charge battery in a well

ventilated area and do not allow a spark or

an open flame near the battery.

FUSE

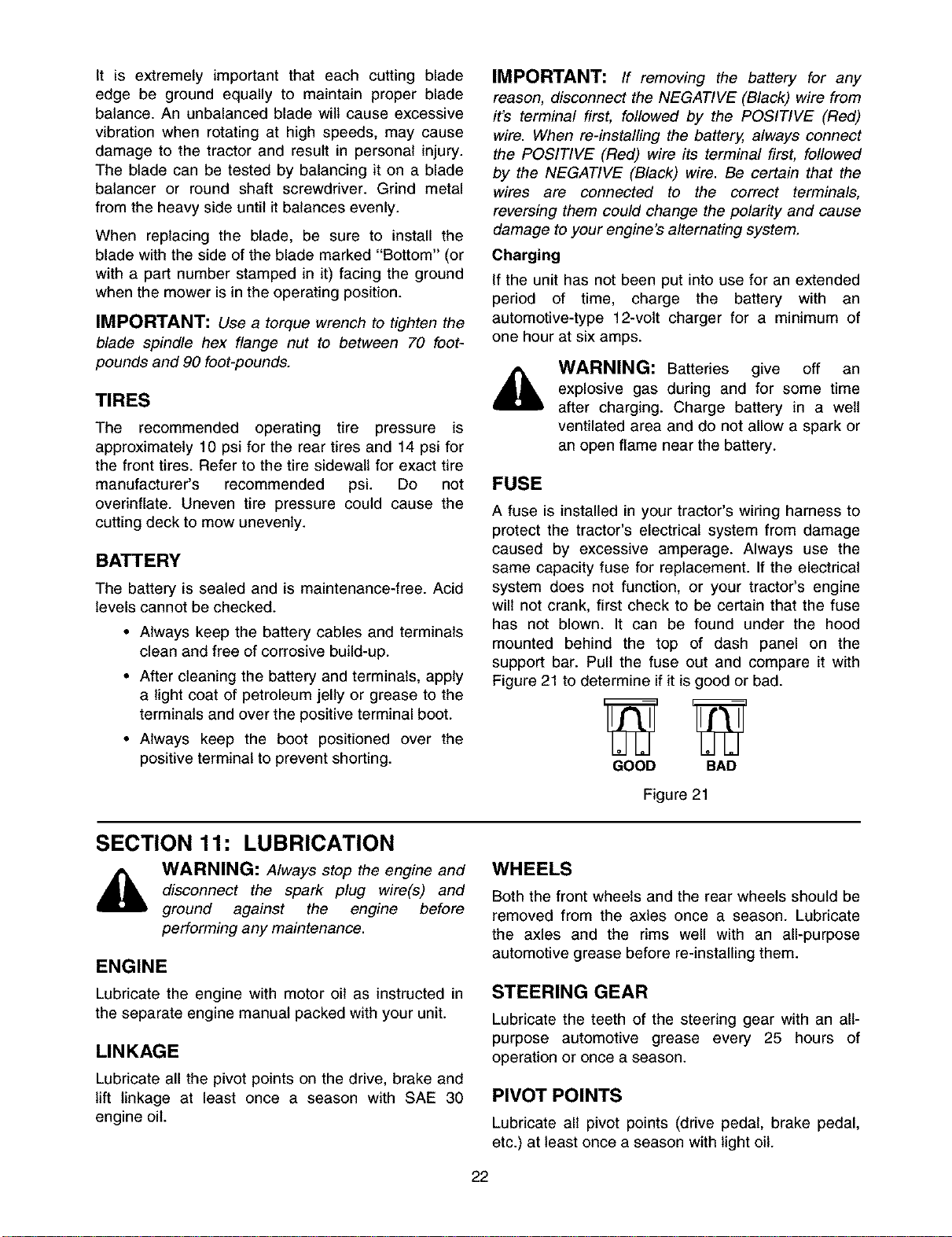

A fuse is installed in your tractor's wiring harness to

protect the tractor's electrical system from damage

caused by excessive amperage. Always use the

same capacity fuse for replacement. If the electrical

system does not function, or your tractor's engine

will not crank, first check to be certain that the fuse

has not blown. It can be found under the hood

mounted behind the top of dash panel on the

support bar. Pull the fuse out and compare it with

Figure 21 to determine if it is good or bad.

GOOD BAD

Figure 21

SECTION 11: LUBRICATION

WARNING: Always stop the engine and

disconnect the spark plug wire(s) and

ground against the engine before

performing any maintenance.

ENGINE

Lubricate the engine with motor oil as instructed in

the separate engine manual packed with your unit.

LINKAGE

Lubricate all the pivot points on the drive, brake and

lift linkage at least once a season with SAE 30

engine oil.

WHEELS

Both the front wheels and the rear wheels should be

removed from the axles once a season. Lubricate

the axles and the rims well with an all-purpose

automotive grease before re-installing them.

STEERING GEAR

Lubricate the teeth of the steering gear with an all-

purpose automotive grease every 25 hours of

operation or once a season.

PIVOT POINTS

Lubricate all pivot points (drive pedal, brake pedal,

etc.) at least once a season with light oil.

22

Loading ...

Loading ...

Loading ...