Loading ...

Loading ...

Loading ...

11.1 AFTER THE FIRST 20 HOURS

OPERATION - FIG. 15

CHANGE THE ENGINE OIL.

i. Unscrew and remove the dipstick followed by

the sump bolt

. Catch the used oil in a

suitable container and dispose of it in an

approved manner.

ii. When all the oil has drained from the engine

block, replace the sump bolt and refill the

engine oil up to the maximum level.

iii. Oil grade SAE10W-30 or equivalent.

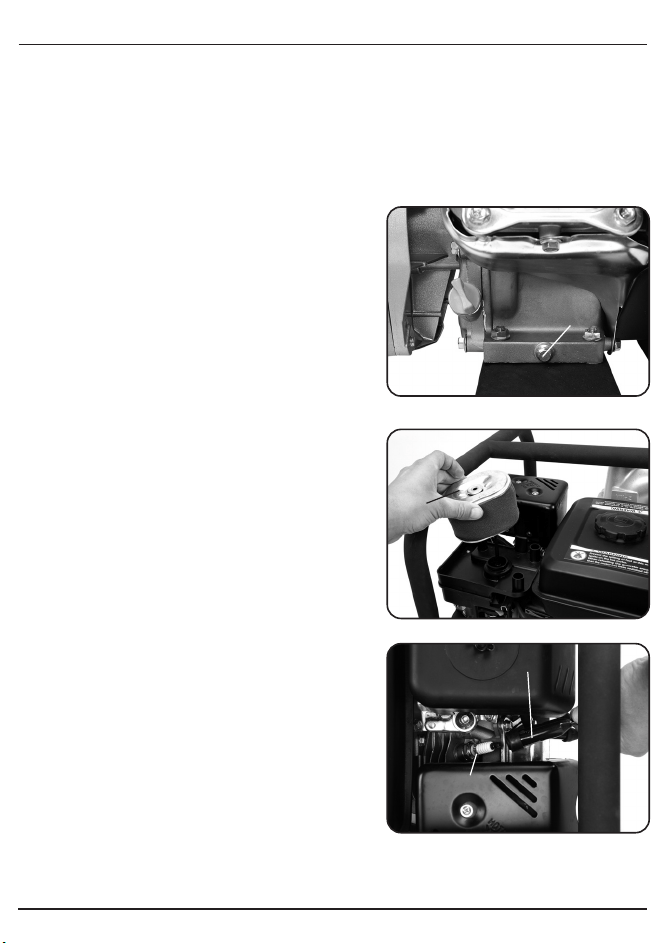

11.2 EVERY 50 HOURS OPERATION -

FIGS. 14 - 17

CHANGE THE AIR FILTER ELEMENT.

CAUTION: Do not run the engine without the air

filter element in place.

i. Unscrew the nut and remove the air filter

housing .

ii. Clean the filter element in paraffin. When

dry soak the filter in clean engine oil.

Squeeze all the excess oil before refitting, and

assembling the housing.

SPARK PLUG INSPECTION

i. Remove spark plug connection by hand.

ii. Remove spark plug with plug spanner

provided.

iii. Inspect the spark plug. It should be a tan colour.

iv. Clean plug and adjust the gap 0.7 - 0.8mm.

v. Replace the spark plug with correct torque:

20Nm (2m.kg 14 ftlb).

vi. Replace spark plug if required.

FIG.15

FIG.16

FIG.17

Make sure that the pump is not running when carrying out maintenance work.

The ‘Draper’ water pump has been designed to operate over a long period of time.

Continuous satisfactory operation depends upon proper machine care, regular cleaning and

by following the periodic maintenance schedule. If the pump is operating in unusually dusty

or hot conditions the time between servicing the pump must be decreased.

Inspect the water pump and extension cables periodically and if damaged have them

repaired by a qualified person or authorised service body. Do not use the pump with

damaged parts.

14

10. BASIC WATER PUMP OPERATION 11. MAINTENANCE

10.3 STARTING THE MACHINE -

FIGS. 11 - 14

After all the instructions and warnings have been

followed and observed the engine is ready to start.

i. Slide the fuel lever to the right; turning on

the fuel supply.

ii. Slide the throttle lever to the left; opening

the throttle a little.

iii. Slide the choke lever to the left; closing the

choke to help with the initial start up.

iv. Turn on the engine switch .

v. Sharply pull the recoil start handle ; do not

let go of the handle. Let the recoil handle

return slowly. Do not pull the rope out fully

while trying to start the engine.

When the engine is running and has warmed up;

i. Reopen the choke so that the engine runs

smoothly.

ii. Increase the throttle speed to being pumping.

NOTE: Whenever the pump is not in use, lower the

idle or switch off the engine.

10.4 STOPPING THE MACHINE

Before stopping the engine, the throttle should be

set to idle and the engine run for a couple of

minutes.

i. If the engine is only being stopped for a

moment; slide the fuel lever to the left and turn

the engine switch

off.

ii. If the engine is being stopped and later stored;

slide the fuel lever to the left and wait for the

engine to cut-out from fuel starvation before

turning the engine switch

off.

NOTE: In the event of an emergency, kill the

engine with switch

.

FIG.11

FIG.12

FIG.13

FIG.14

15

Loading ...

Loading ...

Loading ...