Loading ...

Loading ...

Loading ...

NARROW TILLING/CULTIVATING -

12-3/4" PATH

• Remove outer tines.

Ioo ool

NOTE: When reassembling outer tines,

be sure right tine assembly (marked =R")

and left tine assembly (marked %") are

mounted to correct side of tine shaft.

TINE OPERATION CHECK

AWARNING: Disconnect spark plug wire

from spark plug to prevent starting while

checking tine operation.

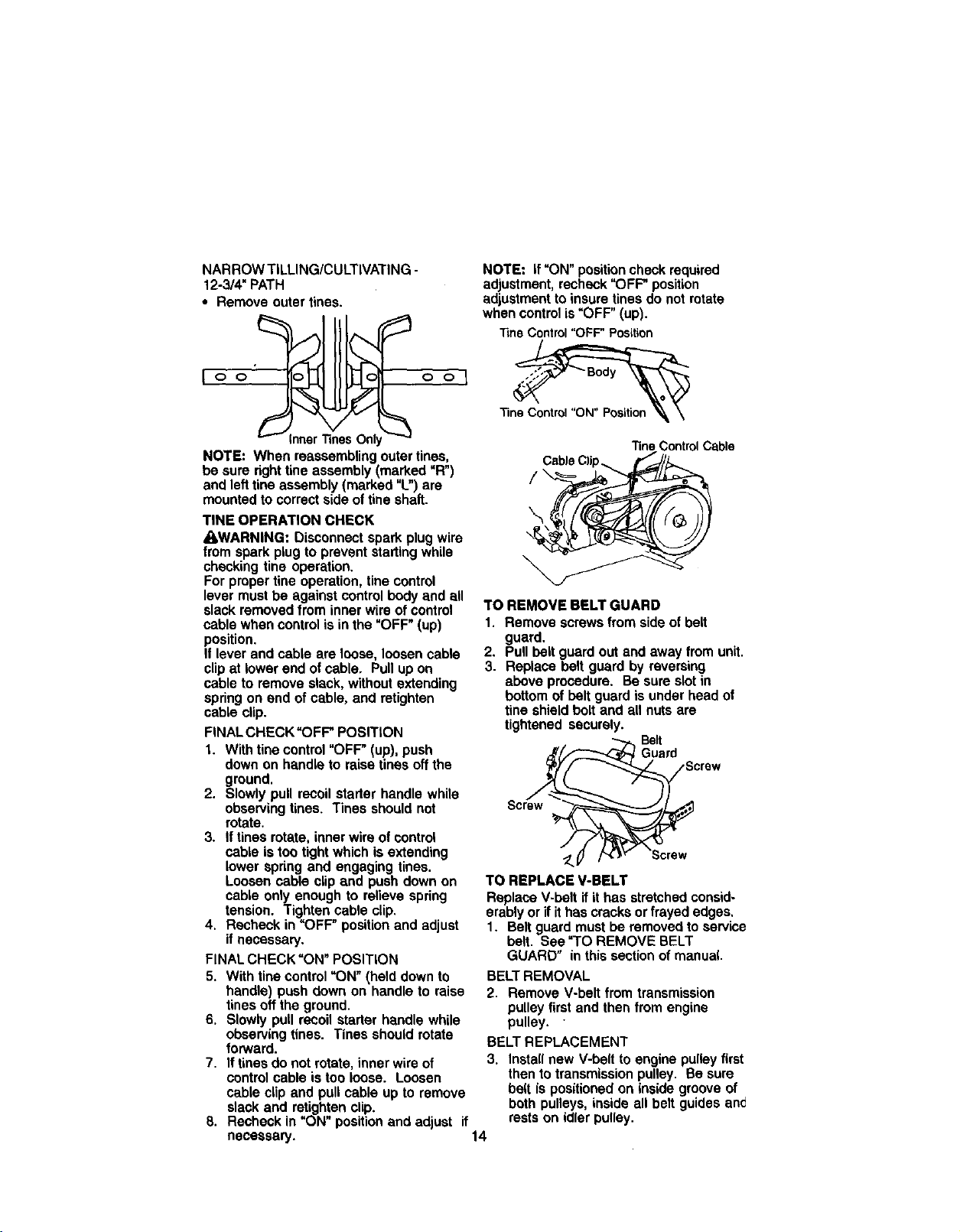

For proper tine operation, tine control

lever must be against control body and all

slack removed from inner wire of control

cable when control is in the "OFF" (up)

position,

If lever and cable are loose, loosen cable

clip at lower end of cable. Pull up on

cable to remove slack, without extending

spring on end of cable, and retighten

cable clip.

FINAL CHECK "OFF" POSITION

1. With tine control "OFF" (up), push

down on handle to raise tines off the

ground.

2. Slowly pull recoil starter handle while

observing tines. Tines should not

rotate,

3. If tines rotate, inner wire of control

cable is too tight which is extending

lower spring and engaging tines.

Loosen cable clip and push down on

cable only enough to relieve spring

tension. Tighten cable clip,

4, Recheck in =OFF" position and adjust

if necessary.

FINAL CHECK "ON" POSITION

5. With fine control "ON" (held down to

handle) push down on handle to raise

tines off the ground.

6, Slowly pull recoil starter handle while

observing tines. Tines should rotate

forward.

7. If tines do not rotate, inner wire of

control cable is too loose. Loosen

cable clip and pull cable up to remove

slack and retighten clip.

8. Recheck in =ON" position and adjust if

necessary.

NOTE: If =ON" position check requtred

adjustment, recheck "OFF" position

adjustment to insure tines do not rotate

when control is =OFF" (up).

"nneControl"OFF"Position

"lineControlCable

\

TO REMOVE BELT GUARD

1. Remove screws from side of belt

guard.

2. Pull bolt guard out and away from unit.

3. Replace belt guard by reversing

above procedure. Be sure slot in

bottom of belt guard is under head of

tine shield bolt and all nuts are

tightened securely.

Scrsw

Screw

:_._ /"_)'_ Screw

TO REPLACE V-BELT

Replace V-belt if it has stretched consid-

erably or if it has cracks or frayed edges,

1. Belt guard must be removed to service

belt. See "TO REMOVE BELT

GUARD" in this section of manual

BELT REMOVAL

2. Remove V-belt from transmission

pulley first and then from engine

pulley. •

BELT REPLACEMENT

3. Install new V-beif to engine pulley first

then to transmission pulley. Be sure

belt is positioned on inside groove of

both pulleys, inside all belt guides and

rests on idler pulley.

14

Loading ...

Loading ...

Loading ...