Loading ...

Loading ...

Loading ...

Part number 550-100-400/0119

116

Troubleshooting (continued)

Check the following:

1. Make sure thermostat is calling for heat and con-

tacts (including appropriate zone controls) are

closed. Check for 24 VAC between thermostat wire

nuts and ground.

2. Make sure all external limit controls are either

installed (and closed) or temporarily jumpered

for testing.

3. Make sure that connectors to control module are

securely plugged in at module and originating

control.

4. Gas pressures:

Maximum: 13” w.c. with no fl ow (lockup) or

with boiler on

Minimum: 4” w.c. (for all except 5” for

-299/310) for natural gas, or 4” w.c. for propane,

with gas fl owing (verify during startup with

boiler at high fi re)

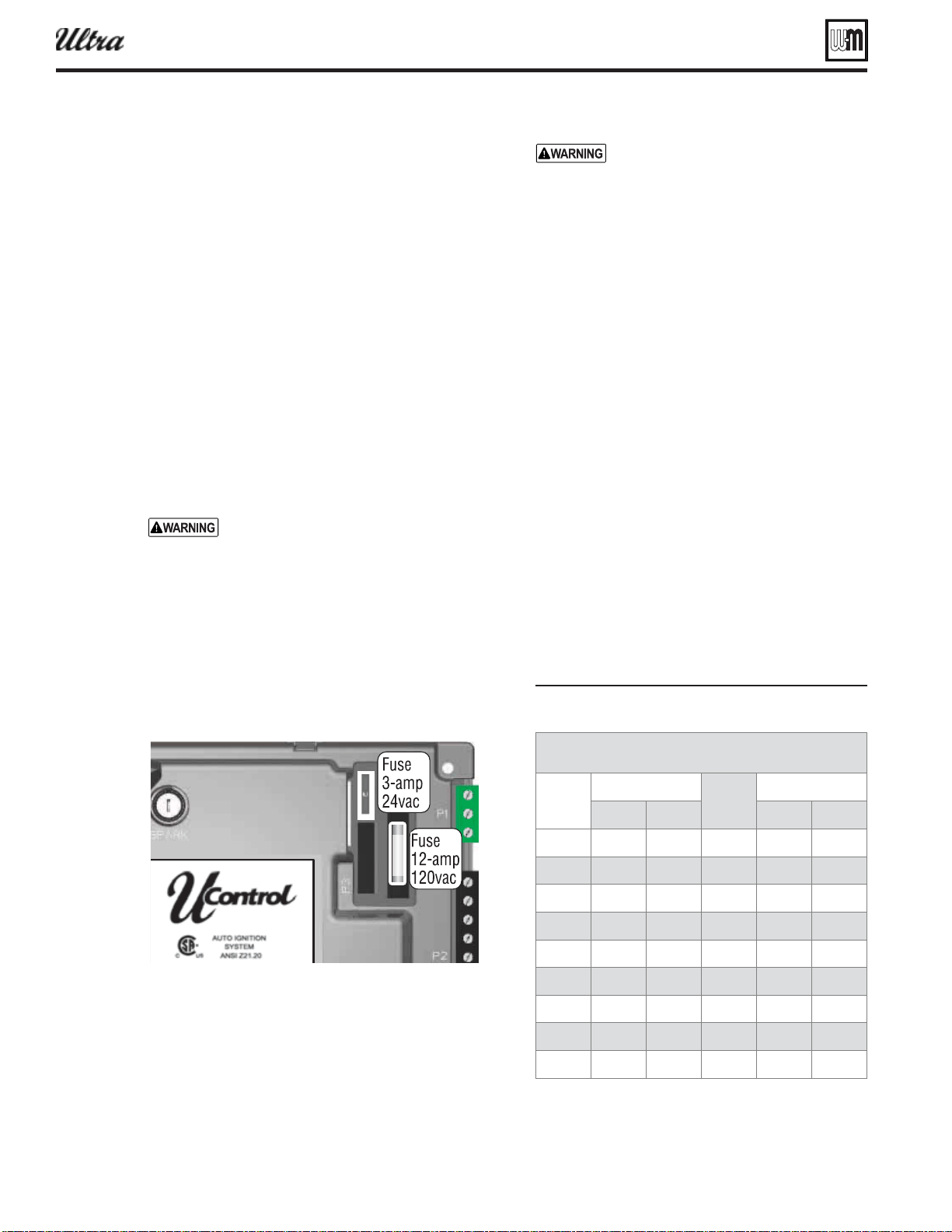

Always check control module fuses

ALWAYS check control module fuses

before replacing control module or any

major components (blower, etc.). If one

of these fuses is blown, it can prevent

control module or other components

from operating.

1. Turn OFF power to boiler at external line switch.

2. Remove jacket door and jacket top panel. Rotate

the swing-away control panel forward to expose

the U-Control module.

3. Remove and inspect the two fuses (located as shown

below).

4. If necessary, replace the fuse:

a. Low voltage circuit fuse is 3-amp fast-blow

(Littelfuse 257003).

b. Line voltage circuit fuse is 12-amp slow-blow

(Littelfuse 326012P).

Do not jumper fuse or replace with any

fuse except as specifi ed. Failure to comply

could result in severe personal injury,

death or substantial property damage.

5. Reinstall jacket top panel and boiler jacket door

after checking the fuses.

6. Restore power to boiler at external line switch and

verify boiler operation after completing boiler

service.

Checking temperature sensors

1. The boiler temperature sensors (flue, outdoor,

return water and supply water) are all resistance-

type devices.

2. Figure 123 shows the correct value for the sensor

at various temperatures.

3. Use the resistance values at 32°F, 60°F, 70°F and

212°F to measure the sensor resistance at known

temperatures (ice point, room temperature and sea

level boiling point). For ice point and boiling point,

insert the sensor in water at that temperature. Use

an ohmmeter to read resistance value.

4. To check whether the control module is correctly

sensing temperature, you can use a resistance de-

cade box. Connect the decade box temporarily in

place of a sensor and read the corresponding tem-

perature on the U-Control display. The temperature

should be close to the value corresponding to the

input resistance.

Figure 123 Sensor resistance alues

®

Series 4

gas-fired water boiler — Boiler Manual

Sensor resistance values

Temp

(°F)

Sensor ohms

Temp

(°F)

Sensor ohms

Min Max Min Max

34265 37871

4517 4992

27834 30764

3698 4088

21630 23907

3043 3364

16944 18727

2517 2782

13372 14780

2091 2311

10629 11747

1744 1928

8504 9399

1461 1615

6847 7568

1229 1359

5545 6129

1038 1147

Loading ...

Loading ...

Loading ...