Loading ...

Loading ...

Loading ...

1. Place boiler in the selected location (as near

chimney as possible). Your boiler is shipped

assembled.Youneedonlyto installthecirculator,

ball valves the relief valve with a drain line to

carryanywater to adrain, andthe drain valve.

2. Install ReliefValveon 3/4"pipenippleintapped

openinginthe leftend section.Connecta drain

line of the same pipe size (3/4" to carry any

water away to a drain. No shutoff of any

descriptionshall be placed betweenthe safety

reliefvalveand theboiler,orondischargepipes

betweensuchsafetyvalvesandtheatmosphere.

Installationofthesafetyreliefvalveshallconform

to the requirements of theANSI/ASME Boiler

and PressureVessel Code,Section IV.

3. Install Drain Valve on lower left side of boiler

as marked.

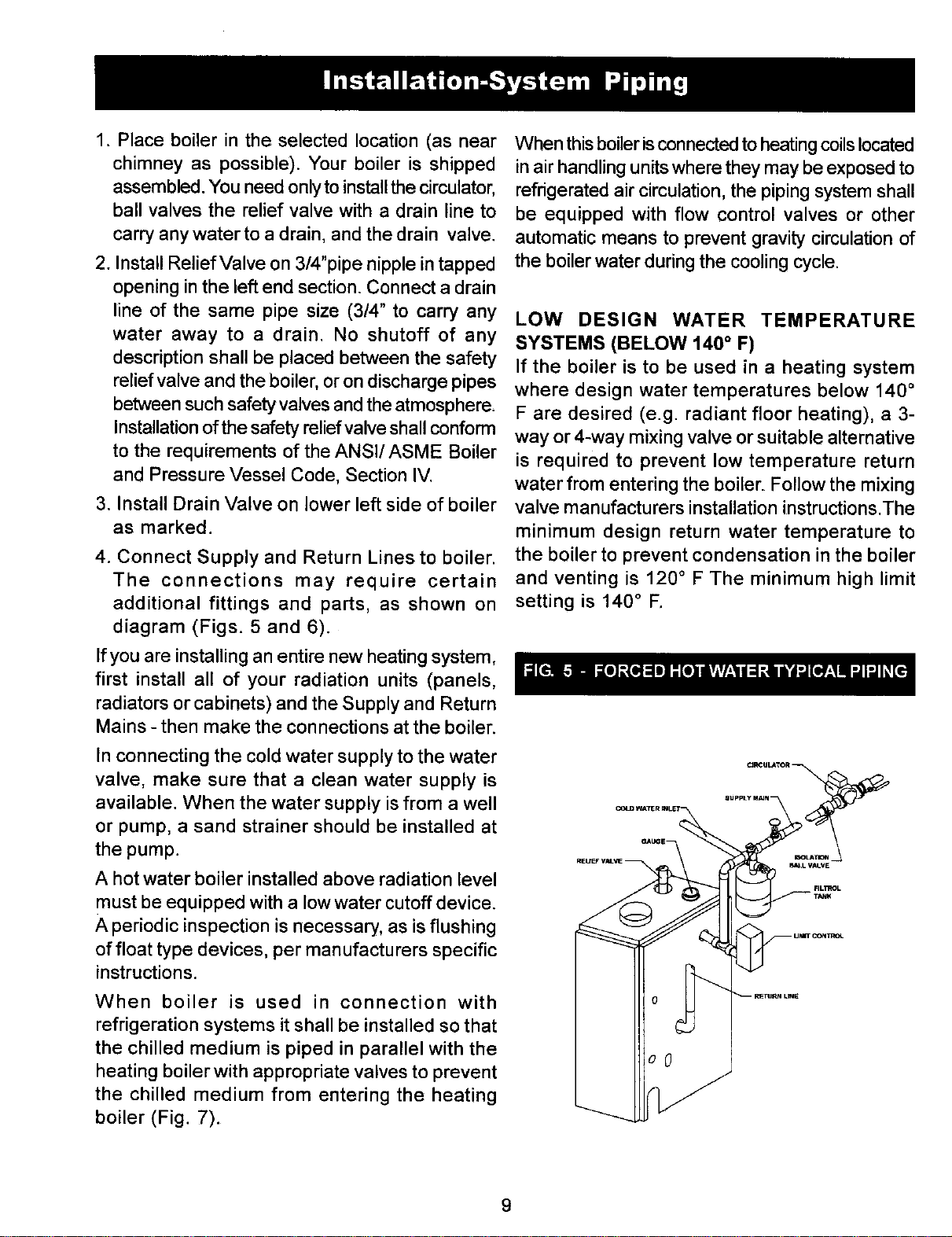

4. Connect Supply and Return Lines to boiler.

The connections may require certain

additional fittings and parts, as shown on

diagram (Figs. 5 and 6).

Ifyou are installing an entire newheatingsystem,

first install all of your radiation units (panels,

radiatorsorcabinets) and theSupplyand Return

Mains- then make the connections atthe boiler.

Inconnecting the cold water supply to the water

valve, make sure that a clean water supply is

available. When the water supply isfrom a well

or pump, a sand strainer should be installed at

the pump.

A hotwaterboiler installed above radiation level

must beequipped with a lowwater cutoff device.

Aperiodic inspection is necessary,as isflushing

of float type devices, per manufacturers specific

instructions.

When boiler is used in connection with

refrigeration systems it shall be installed sothat

the chilled medium is piped in parallel with the

heating boiler with appropriate valves to prevent

the chilled medium from entering the heating

boiler (Fig. 7).

When this boiler isconnected to heating coils located

in air handling units where they may be exposed to

refrigerated air circulation, the piping system shall

be equipped with flow control valves or other

automatic means to prevent gravity circulation of

the boiler water during the cooling cycle.

LOW DESIGN WATER TEMPERATURE

SYSTEMS (BELOW 140 ° F)

If the boiler is to be used in a heating system

where design water temperatures below 140 °

F are desired (e.g. radiant floor heating), a 3-

way or 4-way mixing valve or suitable alternative

is required to prevent low temperature return

water from entering the boiler. Follow the mixing

valve manufacturers installation instructions.The

minimum design return water temperature to

the boiler to prevent condensation in the boiler

and venting is 120 ° F The minimum high limit

setting is 140 ° F.

9

Loading ...

Loading ...

Loading ...