Loading ...

Loading ...

Loading ...

CLEANINGYOUR BOILERAND BURNERS

Flue passages between sections should be

examined yearly and cleaned if necessary. To

clean, remove burners, pilot and vent pipe.

Remove top and front jacket panels. Split the

silicone seal on the flue collector and the clean

out plates with a razor knife. Remove flue collector.

Remove clean out plates by tapping upwards on

the bottom of the plate with a hammer. Remove

loose silicone sealant from sections, flue collector,

and clean out plates. Clean passageways

between sections with a flexible handle wire brush

and a straightened out wire coat hanger. Remove

dirt from the bottom of the boiler and from

between sections by vacuuming. Make sure all

flame ports in burners are open and clear: Shake

out or blow out all loose dirt in burners. Reassemble

all parts. Seal flue collector and clean out plates to

sections with silicone sealant (400 ° F RTV silicone

sealant or equivalent). Reseal seams between

adjacent sections where necessary. All joints must

be airtight. Be sure to check tightness of pilot

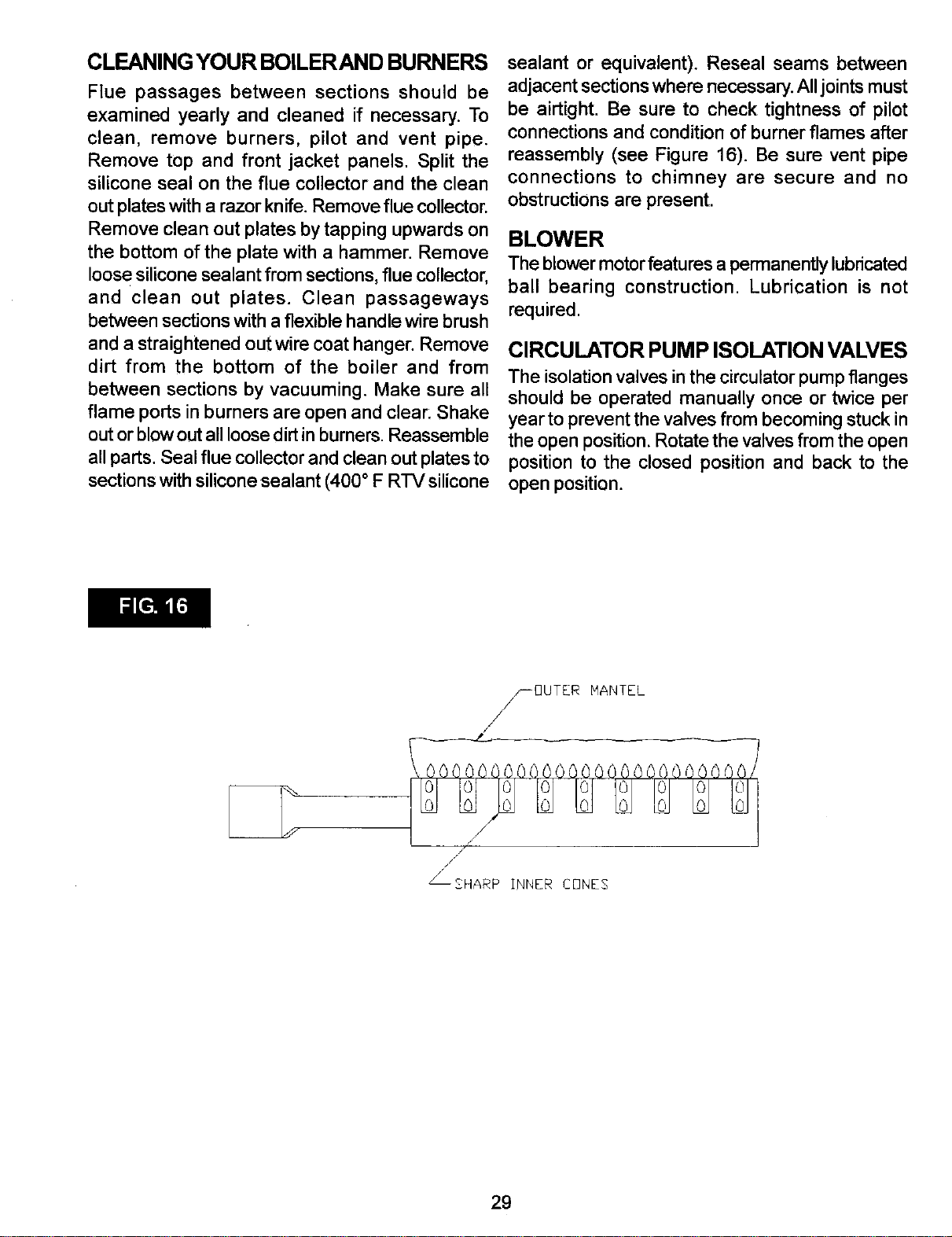

connections and condition of burner flames after

reassembly (see Figure 16). Be sure vent pipe

connections to chimney are secure and no

obstructions are present.

BLOWER

The blower motor features a permanently lubricated

ball bearing construction. Lubrication is not

required.

CIRCULATOR PUMP ISOLATIONVALVES

The isolation valves in the circulator pump flanges

should be operated manually once or twice per

year to prevent the valves from becoming stuck in

the open position. Rotate the valves from the open

position to the closed position and back to the

open position.

f-OUTER lqANTEL

/

z /

J

_SHARP INNER C[3NE$

29

Loading ...

Loading ...

Loading ...