Loading ...

Loading ...

Loading ...

18

Vent System Chart (29" Wide Long Vent

WED/WGD4985 and WED/WGD4995 Models Only)

Number of 90°

turns or elbows

Type of vent Box/louvered or

Angled hoods

0 Rigid metal 160 ft (48.8 m)

1 Rigid metal 150 ft (45.7 m)

2 Rigid metal 140 ft (42.7 m)

3 Rigid metal 130 ft (39.6 m)

4 Rigid metal 120 ft (36.6 m)

5 Rigid metal 110 ft (33.5 m)

NOTE: For long vent systems, use of box/louvered hoods will

improve venting regardless of length.

Additional Elbows

In cases in which the Installation Instructions do not address the

vent length for the specific number of elbows required for a

particular application, the following calculations may be used.

(The total vent system length includes all straight and curved

portions of the vent system):

� For 90° elbows, reduce the allowable vent system length by

10 ft (3.05 m).

� For 45° elbows, reduce the allowable vent system length by

6 ft (1.83 m).

For example, if the Installation Instructions state that a dryer is

allowed 40 ft (12.2 m) of total vent length with two 90° bends, the

total allowable vent length would be reduced by 20 ft (6.0 m) (from

40 ft [12.2 m] to 20 ft [6.0m]).

Install Vent System

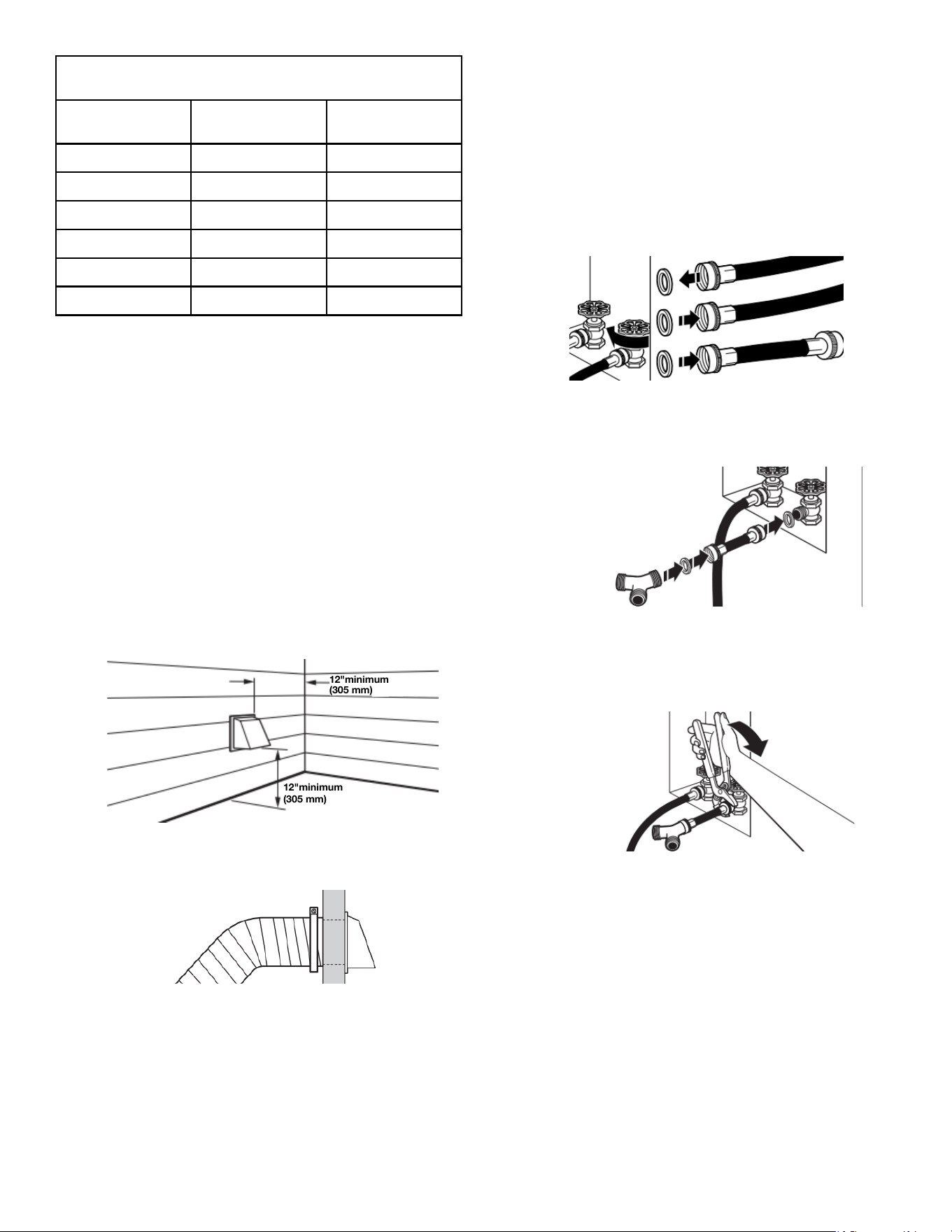

1. Install exhaust hood

12"minimum

(305 mm)

12"minimum

(305 mm)

Install exhaust hood and use caulking compound to seal

exterior wall opening around exhaust hood.

2. Connect vent to exhaust hood

Vent must fit over the exhaust hood. Secure vent to exhaust

hood with 4" (102 mm) clamp. Run vent to dryer location

using straightest path possible. Avoid 90° turns. Use clamps

to seal all joints. Do not use duct tape, screws, or other

fastening devices that extend into interior of vent to secure

vent, because they can catch lint.

Connect Inlet Hoses

For vented, non-steam models, skip to “Connect Vent.” The dryer

must be connected to the cold water faucet using the new inlet

hoses. Do not use old hoses.

NOTE: Replace inlet hoses after 5 years of use to reduce the risk

of hose failure. Record hose installation or replacement dates on

the hoses for future reference.

Periodically inspect and replace hoses if bulges, kinks, cuts, wear,

or leaks are found.

1. Turn cold water off, remove and replace rubber

washer

Turn cold water faucet off and remove washer inlet hose.

Remove old rubber washer from inlet hose and replace with

new rubber washer.

2. Attach short hose and “Y” connector

Attach 2 ft (0.6 m) inlet hose to cold water faucet. Screw on

coupling by hand until it is seated on faucet. Then attach “Y”

connector to male end of the 2 ft (0.6 m) inlet hose. Screw on

coupling by hand until it is seated on connector.

3. Tighten couplings

Using pliers, tighten the couplings with additional two-thirds

turn.

NOTE: Do not overtighten. Damage to the coupling can

result.

Loading ...

Loading ...

Loading ...