Loading ...

Loading ...

Loading ...

24

WORKTOPS/UNDERCOUNTERS & SANDWICH UNITS

OPERATIONS MANUAL

1. All refrigerant lines and components must be clean, free of

burrs and purged with nitrogen prior to and during brazing

or soldering connections. Nitrogen purging during braz-

ing or soldering will eliminate carbon or foreign matter

contamination. Any system restrictions or contamination is

the responsibility of the installer.

2. Condensing unit or compressor shall not be left open to

the atmosphere for more than five (5) minutes.

3. No refrigeration component, tubing or fitting shall be left

open to the atmosphere for more than ½ hour without

being soldered, capped or plugged.

4. Each completed refrigeration system shall be purged with

150psi of dry nitrogen for at least six (6) seconds, then

pressurized with at least 165psi of nitrogen for pressure

check (making sure to energize any solenoid valves to

assure access). Leak-check all joints, flare fittings and

valves and make sure there is no pressure drop within the

system.

5. System evacuation is of the utmost importance with NON-

CFC refrigerant systems. System must be evacuated to a

minimum of 200 microns. In addition, a vacuum decay

test is strongly recommended to assure there is not a

large pressure differential between the system and the

vacuum pump. System must be evacuated from both high

and low sides of the system using heavy duty vacuum

hoses.

6. Each system should be charged with the refrigerant type

as specified on the cabinet data tag. This refrigerant type

should match the type listed on the condensing unit being

used. The refrigerant charge should be held to the mini-

mum required for the satisfactory pull down and opera-

tion. For an accurate indication of refrigerant charge, the

sight glass will show a full column of liquid.

7. The superheat reading taken 6” from the compressor suc-

tion valve should be 30° +/- 5°. Expansion valve adjust-

ment may be necessary to achieve this superheat.

8. Installation of the electric condensate heater is also the

responsibility of the installer (see “Installing Electric

Condensate Heater” under “Optional Accessories”).

CAUTION: EXTREME CARE MUST BE USED WHEN

ACCESSING THE SYSTEM DURING INSTALLATION. DUE

TO THE COMPLEXITY OF REMOTE REFRIGERATION

SYSTEMS AND THE POTENTIAL FOR IMPROPER

INSTALLATION, ANY RESTRICTIONS, LEAKS, FAILED OR

DAMAGED COMPONENTS CAUSED BY CONTAMINANTS

ARE NOT THE RESPONSIBILITY OF CONTINENTAL

REFRIGERATOR.

REMOTE SET-UP AND INSTALLATION GUIDELINES

All remote refrigerators and freezers are shipped with an expan-

sion valve, thermostat and defrost timer (freezer only), installed

from the factory. The installer is responsible for connecting all

refrigerant lines, liquid line drier, sight glass, solenoid, head

pressure control, hi/low pressure safety, crankcase heater, con-

densing unit and any other accessories as well as wiring. The

evaporator section has been factory leak checked with helium,

however; due to vibration in transit, the entire system must be

thoroughly leak checked after installation and prior to start-up.

The final leak inspection of the entire completed refrigeration

system and all of its components as well as start-up and the

operation of the refrigeration system is the sole responsibility

of the installer.

The CFC-Free refrigerant used in standard remote and self-con-

tained models is R-134a for refrigerators and R-404a for freez-

ers. All compressors and systems designed for these refrigerant

utilize polyolester oil as their main lubricant, which absorbs

moisture from the ambient surroundings extremely fast and

in much greater quantity than conventional mineral oils. Since

moisture levels greater than 100 PPM will result in system cor-

rosion and ultimate failure, it is imperative that the compressor,

components and entire system be kept sealed.

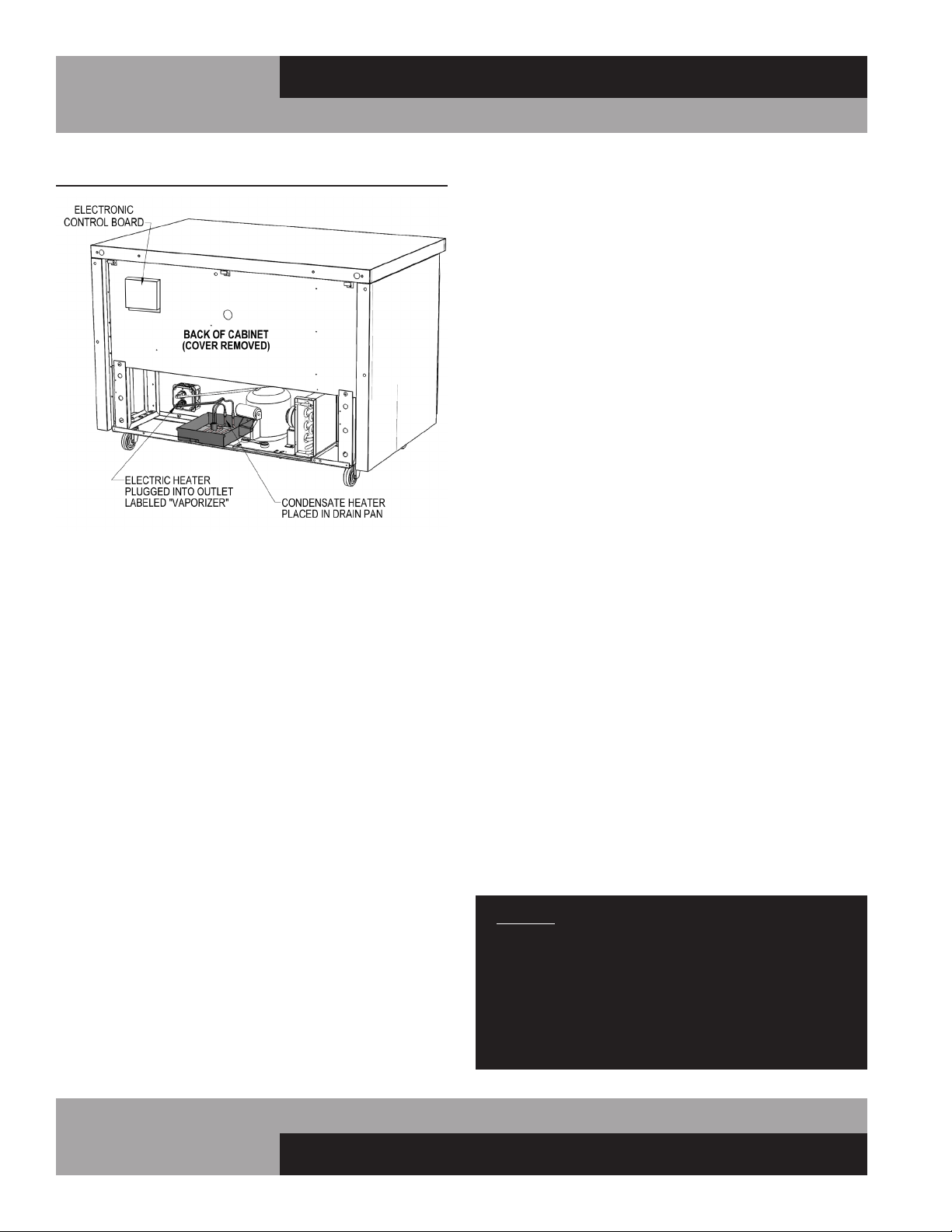

FIGURE 19: Electric Condensate Heater

Loading ...

Loading ...

Loading ...