Loading ...

Loading ...

A

WARNING: To prevent accidental starting that

could cause possible serious personal injury,

assemble all parts to your saw completely before

connecting itto power supply• Saw should never

be connected to power supply when you are

assembling parts, making adjustments, installing

or removing blades or accessodas, or when not

in use.

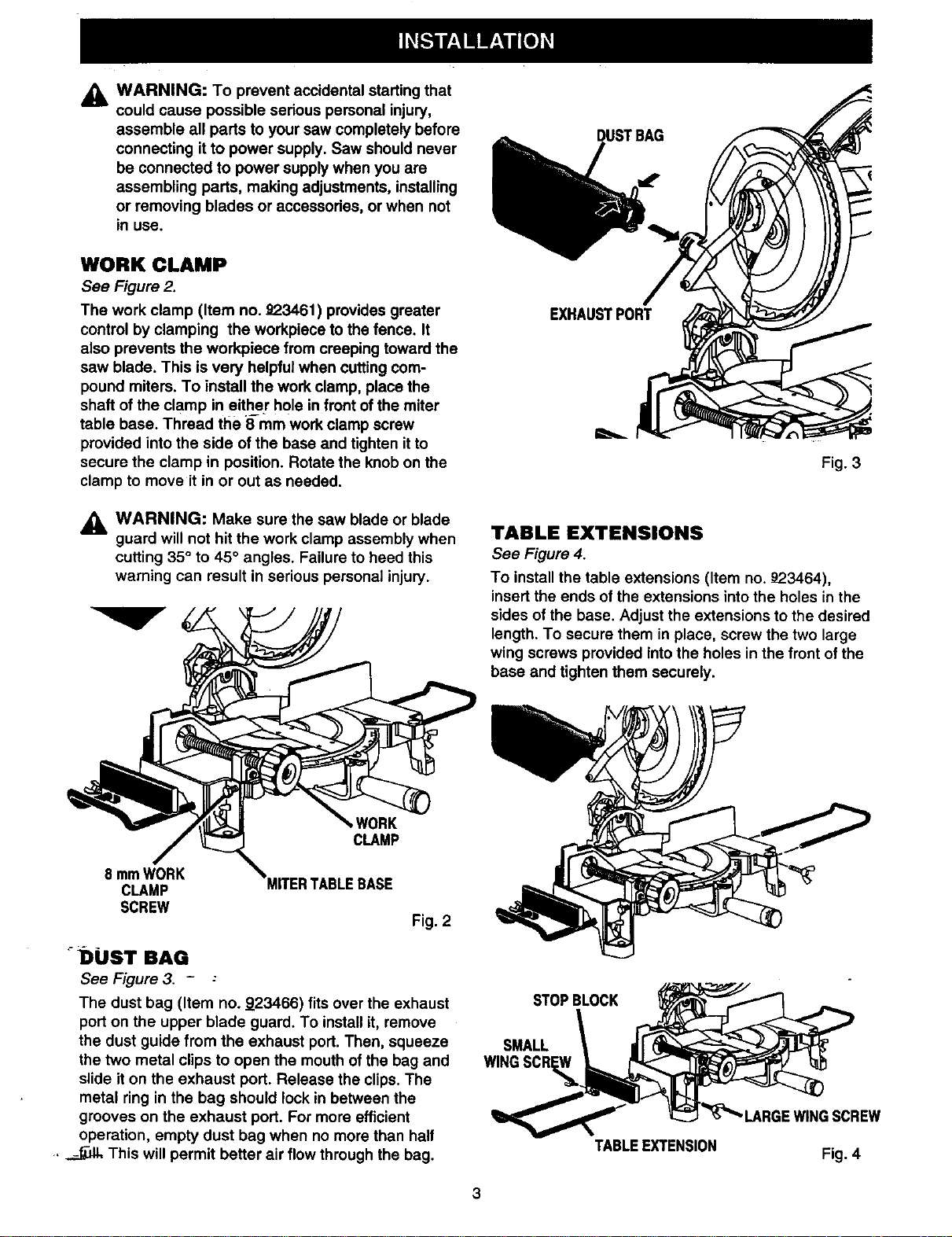

WORK CLAMP

See Figure 2.

The work clamp (Item no. 92.3461) provides greater

control by clamping the workpiece to the fence. It

also prevents the workpiece from creeping toward the

saw blade. This is very helpful when cutting com-

pound miters. To install the work clamp, place the

shaft of the clamp in either hole in front of the miter

table base. Thread the 8 mm work clamp screw

provided into the side of the base and tighten itto

secure the clamp in position. Rotate the knob on the

clamp to move it in or out as needed.

_IL WARNING: Make sure the saw blade or blade

guard will not hit the work clamp assembly when

cutting 35° to 45° angles. Failure to heed this

warning can result in serious personal injury.

EXHAUSTPORT

Fig. 3

TABLE EXTENSIONS

See Figure 4.

To install the table extensions (Item no. _23464),

insert the ends of the extensions intothe holes in the

sides of the base. Adjust the extensions to the desired

length. To secure them in place, screw the two large

wing screws provided intothe holes in the front ofthe

base and tighten them securely.

8 mmWORK

CLAMP

SCREW

tVORK

CLAMP

° DUST BAG

See Figure 3. - :

Fig. 2

The dust bag (Item no. 923466) fits over the exhaust

port on the upper blade guard. To install it, remove

the dust guide from the exhaust port. Then, squeeze

the two metal clips to open the mouth of the bag and

slide it on the exhaust port. Release the clips. The

metal ring in the bag should lock in between the

grooves on the exhaust port. For more efficient

operation, empty dust bag when no more than half

• _ This will permit better air flow through the bag.

STOPBLOCK

SMALL

WIN4

TABLEEXTENSION

; SCREW

Fig. 4

Loading ...