Loading ...

Loading ...

Loading ...

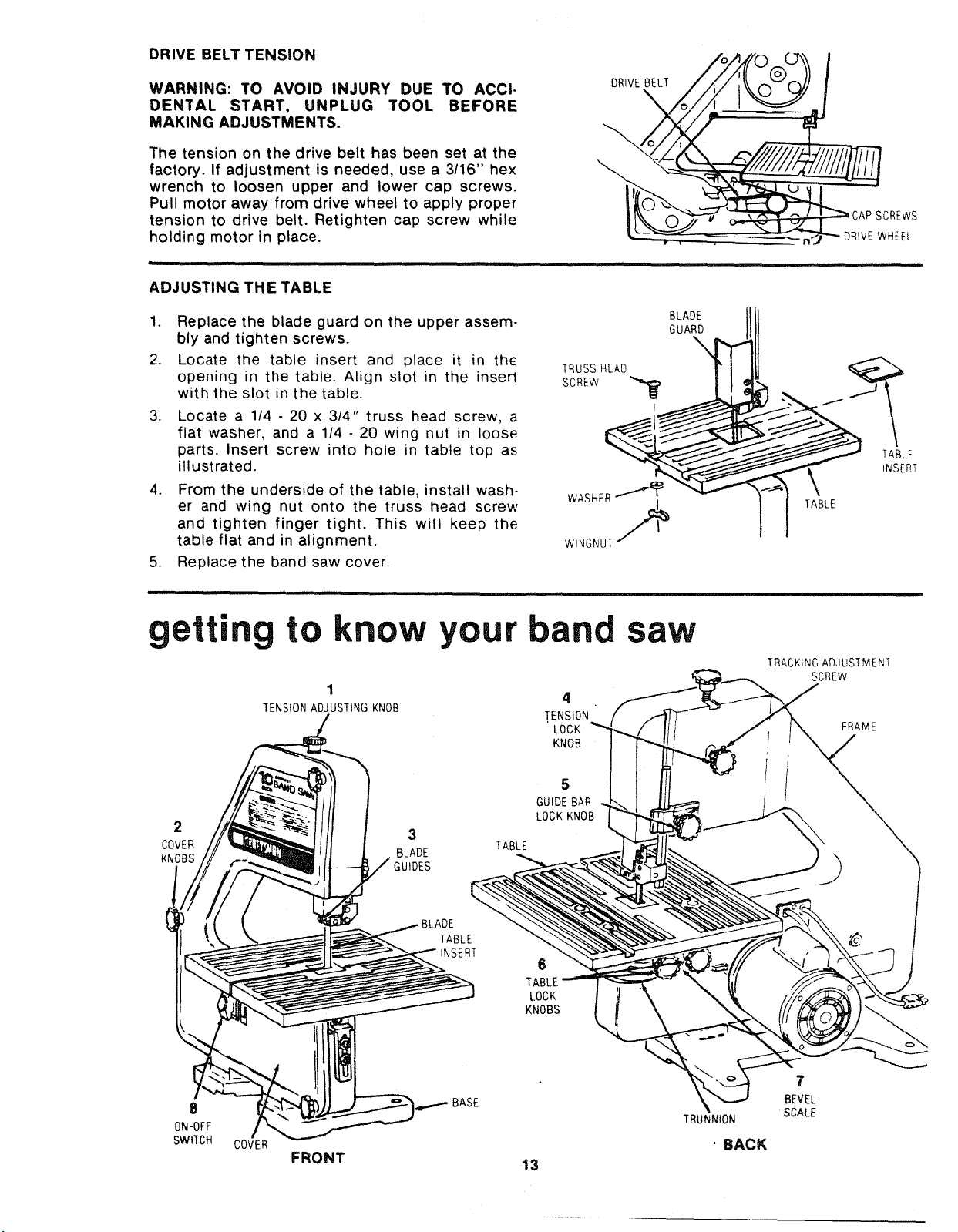

DRIVE BELT TENSION

WARNING: TO AVOID INJURY DUE TO ACCI-

DENTAL START, UNPLUG TOOL BEFORE

MAKING ADJUSTMENTS.

The tension on the drive belt has been set at the

factory. If adjustment is needed, use a 3/16" hex

wrench to loosen upper and lower cap screws.

Pull motor away from drive wheel to apply proper

tension to drive belt. Retighten cap screw while

holding motor in place.

ADJUSTING THE TABLE

DRIVEBELT

CAP SCREWS

DRIVE WHEEL

1. Replace the blade guard on the upper assem-

bly and tighten screws.

2. Locate the table insert and place it in the

opening in the table. Align slot in the insert

with the slot in the table.

.

Locate a 1/4 - 20 x 3/4" truss head screw, a

flat washer, and a 1/4 - 20 wing nut in loose

parts. Insert screw into hole in table top as

illustrated.

4. From the underside of the table, install wash-

er and wing nut onto the truss head screw

and tighten finger tight. This will keep the

table flat and in alignment.

5. Replace the band saw cover.

"[RUSSHEAD

SCREW

BLADE

GUARD

\

TABLE

TABLE

INSERT

erring to

2

COVER

KNOBS

now

1

TENSION ADJUSTING KNOB

3

BLADE

GUIDES

your ban

4

TENSION

LOCK

KNOB

5

GUIDE BAR

LOCK KNOB

"[ABLE

saw

TRACKING ADJUSTMENT

SCREW

FRAME

ADE

TABLE

INSERT

6

LOCK

KNOBS

8

ON-OFF

SWITCH

COVER

FRONT

BASE

13

TRUNNION

'BACK

7

BEVEL

SCALE

Loading ...

Loading ...

Loading ...