Loading ...

Loading ...

Loading ...

8

SECTION: D START-UP OPERATION

D-1) Check Voltage and Phase:

Before operating pump, compare the voltage and phase

information stamped on the pump identifi cation plate to the

available power.

D-2) Check Pump Rotation:

Before putting pump into service for the fi rst time, the motor

rotation must be checked. Improper motor rotation can

result in poor pump performance and can damage the motor

and/or pump. To check the rotation, suspend the pump

freely, momentarily apply power and observe the “kickback”.

“Kickback” should always be in a counter-clockwise direction

as viewed from the top of the pump motor housing.

D-2.1) Incorrect Rotation for Single-Phase Pumps:

In the unlikely event that the rotation is incorrect for a single

phase pump, contact a Barnes Pumps Service Center.

D-3) Start-Up Report:

Included at the end of this manual is a start-up report form,

this form is to be completed as applicord. Return one copy to

Barnes Pumps, Inc. and store a copy in the control panel or

with the pump manual if no control panel is used. It is important

to record this data at initial start-up since it will be useful to

refer to should servicing the pump be required in the future.

D-3.1) Identifi cation Plate:

Record the numbers from the pump identifi cation plate on

both START-UP REPORT provided at the end of the manual

for future reference.

D-3.2) Insulation Test:

Before the pump is put into service, an insulation (megger)

test should be performed on the motor. The resistance values

(ohms) as well as the voltage (volts) and current (amps)

should be recorded on the start-up report.

D-3.3) Pump-Down Test:

After the pump has been properly wired and lowered into the

basin, sump or lift station, it is advisable to check the system

by fi lling with liquid and allowing the pump to operate through

its pumping cycle. The time needed to empty the system, or

pump-down time along with the volume of water, should be

recorded on the start-up report.

SECTION E: PREVENTATIVE MAINTENANCE

As the motor is oil fi lled, no lubrication or other maintenance

is required, and generally Barnes Pumps will give very

reliable service and can be expected to operate for years on

normal sewage pumping without failing. However as with any

mechanical piece of equipment a preventive maintenance

program is recommended and suggested to include the

following checks:

1) Inspect motor chamber for oil level and contamination

and repair as required per section F-1.

2) Inspect impeller and body for excessive build-up or

clogging and repair as required per section F-2.

3) Inspect motor and bearings and replace as required

per section F-3.

4) Inspect seal for wear or leakage and repair as required

per section F-4.

SECTION F: SERVICE AND REPAIR

NOTE: All item numbers in ( ) refer to Figures 15 and 16.

F-1) Lubrication:

Anytime the pump is removed from operation, the cooling oil

in the motor housing (6) should be checked visually for oil

level and contamination.

F-1.1) Checking Oil:

Motor Housing - To check oil, set unit upright. Remove pipe

plug (39) from motor housing (6). With a fl ashlight, visually

inspect the oil in the motor housing (6) to make sure it is

clean and clear, light amber in color and free from suspended

particles. Milky white oil indicates the presence of water. Oil

level should be just above the motor when pump is in vertical

position.

F-1.2) Testing Oil:

1.) Place pump on it’s side, remove pipe plug (39), from

motor housing (6) and drain oil into a clean, dry container.

2.) Check oil for contamination using an oil tester with a

range to 30 Kilovolts breakdown.

3.) If oil is found to be clean and uncontaminated

(measuring above 15 KV. breakdown), refi ll the motor

housing as per section F-1.4.

4.) If oil is found to be dirty or contaminated (or measures

below 15 KV. breakdown), the pump must be carefully

inspected for leaks at the shaft seal (28), cord

assembly (16), square ring (27) and pipe plug (39),

before refi lling with oil. To locate the leak, perform a

pressure test as per section F-1.3. After leak is repaired,

dispose of old oil properly, and refi ll with new oil as per

section F-1.4.

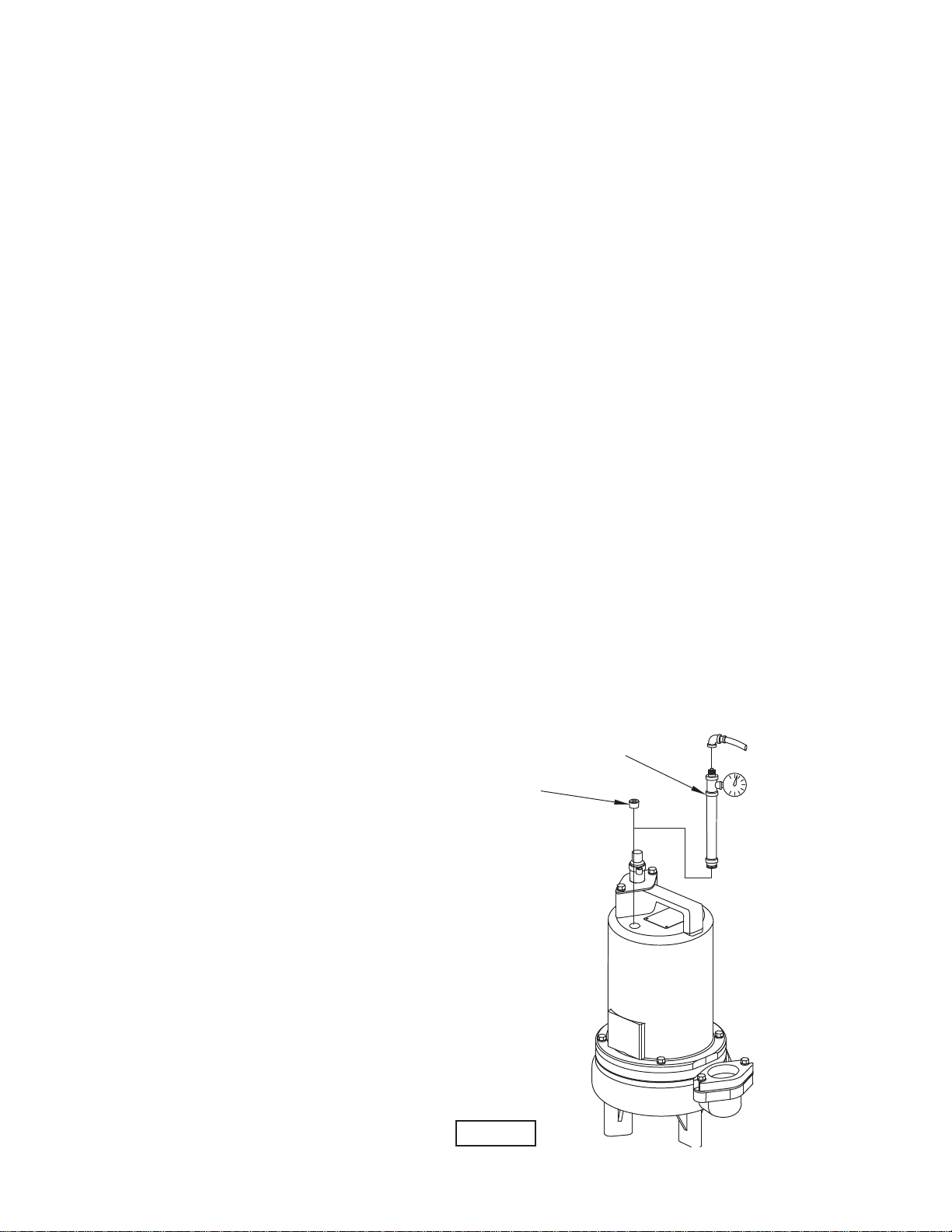

F-1.3) Pressure Test:

Pumps that have been disassembled, Motor Housing - If the

pump has been disassembled, the oil should be drained before

a pressure test, as described in section F-1.1. Remove pipe

plug (39) from motor housing (6). Apply pipe sealant to pressure

gauge assembly and tighten into hole (See Figure 4).

FIGURE 4

Remove Plug

Pressure Gauge Assy

(See Parts List)

10 PSI

AIR

Loading ...

Loading ...

Loading ...