Loading ...

Loading ...

Loading ...

SERVmCmNG THE UNmT

Extreme care and knowbdge of the system is required

when servicing this unit. Service should be performed by

qualified service personnel only. Replacement parts for

this unit must be identical to the parts they replace. Refer

any repair to an authorized service deabr.

mNSPECTmNG/REPLACmNG THE DRmVE BELT

When servicing the unit, use only original equipment

manufacturer replacement parts, inspect the drive belt

once a year or every 50 hours of operation, whichever

comes first, for wear. if the drive belt needs to be

rephced, use the following instructions.

WARNING: Toavoidserious

personal injury, turn

off the unit and allow it to cool Unplug the

unit before you perform any maintenance.

1. Remove the flange lock nut from the belt case cover

with a wrench or nut driver (Fig. 9).

2. Remove the seven (7) screws from the belt case

cover using a #T20 Torx bit or fiat blade screwdriver

(Fig. 9).

WARNING: Toreducetheriskof

electricalshock,

replacethe cover beforeconnectingthe

unit to a power source.

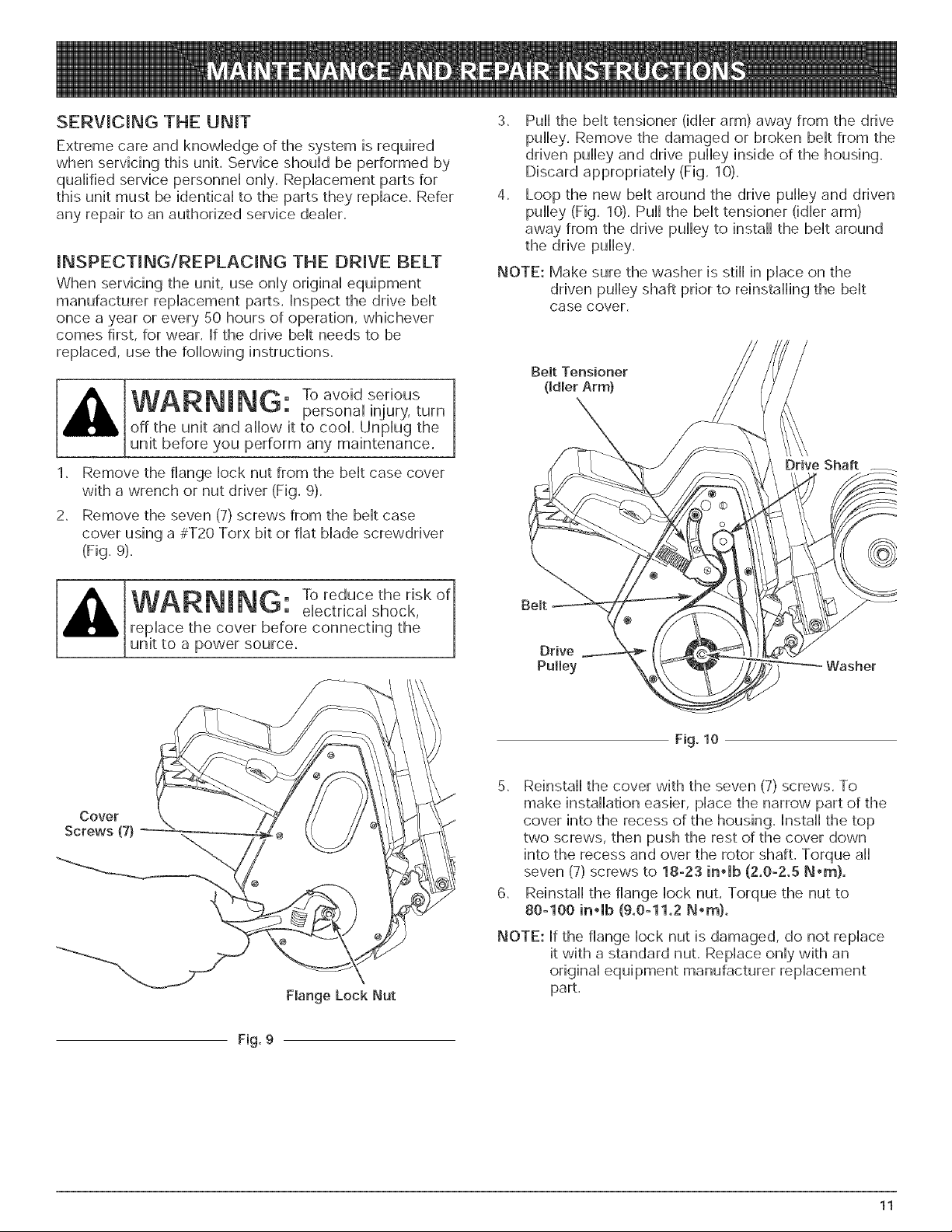

3. Puii the belt tensioner (idler arm) away from the drive

pulley. Remove the damaged or broken belt from the

driven pulley and drive pulley inside of the housing.

Discard appropriately (Fig. 10).

4. Loop the new belt around the drive pulley and driven

pulley (Fig. 10). Puii the belt tensioner (idler arm)

away from the drive pulley to instaii the belt around

the drive pulley.

NOTE: Make sure the washer is stiii in place on the

driven pulley shaft prior to reinstalling the belt

case cover.

Belt Tensioner

(Idler Arm}

Drive Shaft

Belt

Fig. 10

Cover

Screws (7)

Flange Lock Nut

5. Reinstall the cover with the seven (7) screws. To

make installation easier, place the narrow part of the

cover into the recess of the housing. Install the top

two screws, then push the rest of the cover down

into the recess and over the rotor shaft. Torque all

seven (7) screws to 18-23 inolb (2.0-2.5 N,m)o

6. Reinstall the flange lock nut. Torque the nut to

80-100 inomb(9.0-11.2 N,m).

NOTE: if the flange lock nut is damaged, do not replace

it with a standard nut. Replace only with an

original equipment manufacturer replacement

part.

Fig. 9

11

Loading ...

Loading ...

Loading ...