Loading ...

Loading ...

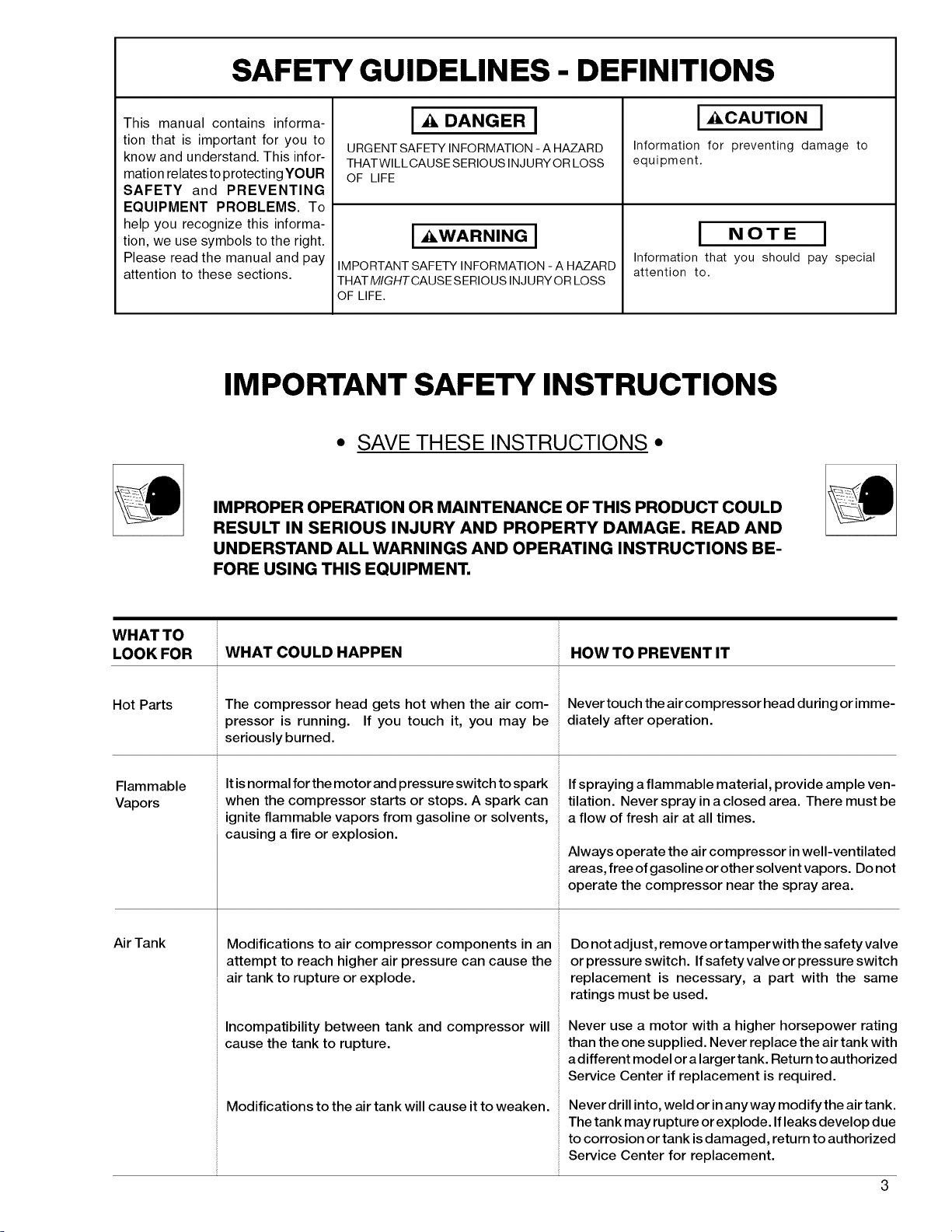

SAFETY GUIDELINES - DEFINITIONS

This manual contains informa-

tion that is important for you to

know and understand. This infor-

mation relates to protecting YOUR

SAFETY and PREVENTING

EQUIPMENT PROBLEMS. To

help you recognize this informa-

tion, we use symbols to the right.

Please read the manual and pay

attention to these sections.

I ,A DANGER I

URGENTSAFETYINFORMATION-A HAZARD

THATWILLCAUSESERIOUSINJURYORLOSS

OF LIFE

I _WARNING I

IMPORTANTSAFETYINFORMATION-A HAZARD

THATMIGHTCAUSESERIOUSINJURYORLOSS

OF LIFE.

I _CAUTION I

Information for preventing damage to

equipment.

I NOTE I

Information that you should pay special

attention to.

IMPORTANT SAFETY INSTRUCTIONS

* SAVE THESE INSTRUCTIONS *

IMPROPER OPERATION OR MAINTENANCE OF THIS PRODUCT COULD

RESULT IN SERIOUS INJURY AND PROPERTY DAMAGE, READ AND

UNDERSTAND ALL WARNINGS AND OPERATING INSTRUCTIONS BE-

FORE USING THIS EQUIPMENT,

WHAT TO

LOOK FOR WHAT COULD HAPPEN HOW TO PREVENT IT

Hot Parts

Flammable

Vapors

Air Tank

The compressor head gets hot when the air com-

pressor is running. If you touch it, you may be

seriously burned.

Itis normal for the motor and pressure switch to spark

when the compressor starts or stops. A spark can

ignite flammable vapors from gasoline or solvents,

causing a fire or explosion.

Modifications to air compressor components in an

attempt to reach higher air pressure can cause the

air tank to rupture or explode.

Incompatibility between tank and compressor will

cause the tank to rupture.

Modifications to the air tank will cause it to weaken.

Never touch the air compressor head during or imme-

diately after operation.

If spraying a flammable material, provide ample ven-

tilation. Never spray in a closed area. There must be

a flow of fresh air at all times.

Always operate the air compressor in well-ventilated

areas, free of gasoline or other solvent vapors. Do not

operate the compressor near the spray area.

Do not adjust, remove or tamper with the safety valve

or pressure switch. Ifsafety valve or pressure switch

replacement is necessary, a part with the same

ratings must be used.

Never use a motor with a higher horsepower rating

than the one supplied. Never replace the air tank with

adifferent model or alarger tank. Return to authorized

Service Center if replacement is required.

Never drill into, weld or in any way modify the air tank.

The tank may rupture or explode. If leaks develop due

to corrosion or tank is damaged, return to authorized

Service Center for replacement.

Loading ...

Loading ...

Loading ...