Loading ...

Loading ...

Loading ...

OPERATION

DEPTH OF CUT ADJUSTMENTS

We recommend that cuts be made at a depth not ex..

¢eedlng 1/8" and that several passes be made to

teach depths of cut greater than 1/8"

loUNPLUG YOUR ROUTER°

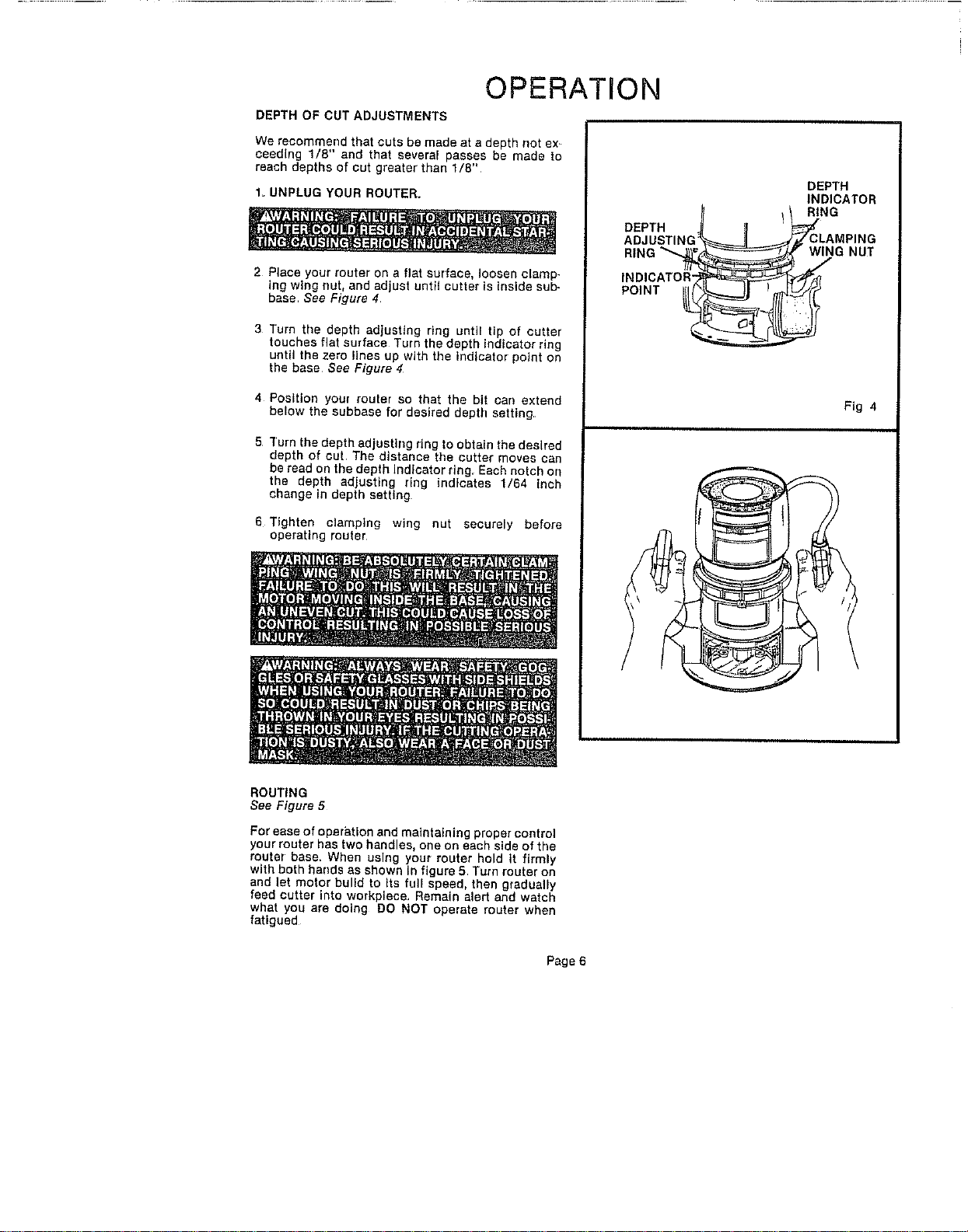

2 Place your router on a flat surface, loosen clamp-

ing wing nut, and adjust until cutter ts Inside sub-

base See Figure 4.

3 Turn the depth adjusting rtng until tip of cutter

touches flat surface Turn the depth indicator ring

until the zero lines up with the Indicator point on

the base See Figure 4

4 Position your router so that the bit san extend

below the subbase for desired depth setting

5 ]'urn the depth adjusting ring to obtain the desired

depth of cut. The distance the cutter moves can

be read on the depth indicator ring. Eash notch on

the depth adjusting ring indicates 1/64 inch

change in depth setting

6 Tighten clamping wing nut securely before

operating router

DEPTH

ADJUSTING:

RING

INDICATOR":

POINT ___

J

DEPTH

INDICATOR

RIND

_CwLAMPING

tNG NUT

Ftg 4

ROUTING

See Figure 5

For ease of operation and maintaining proper control

your router has two handles, one on each side of the

router base. When uelng your router ho_d tt firmly

with both hands as shown In figure 5 Turn router on

and let motor build to Its full speed, then gradually

feed cutter into workpieca. Rama(n alert and watch

what you are doing DO NOT operate router when

fatigued

Page 6

Loading ...

Loading ...

Loading ...