Loading ...

Loading ...

Loading ...

- CARE OF YOUR REVERSE OSMOSIS SYSTEM -

TUBING CONNECTION (continued)

If tubing is used) other than supplied with the sys-

tem, be sure it is of high quality, exact size and round-

ness with a smooth surface.

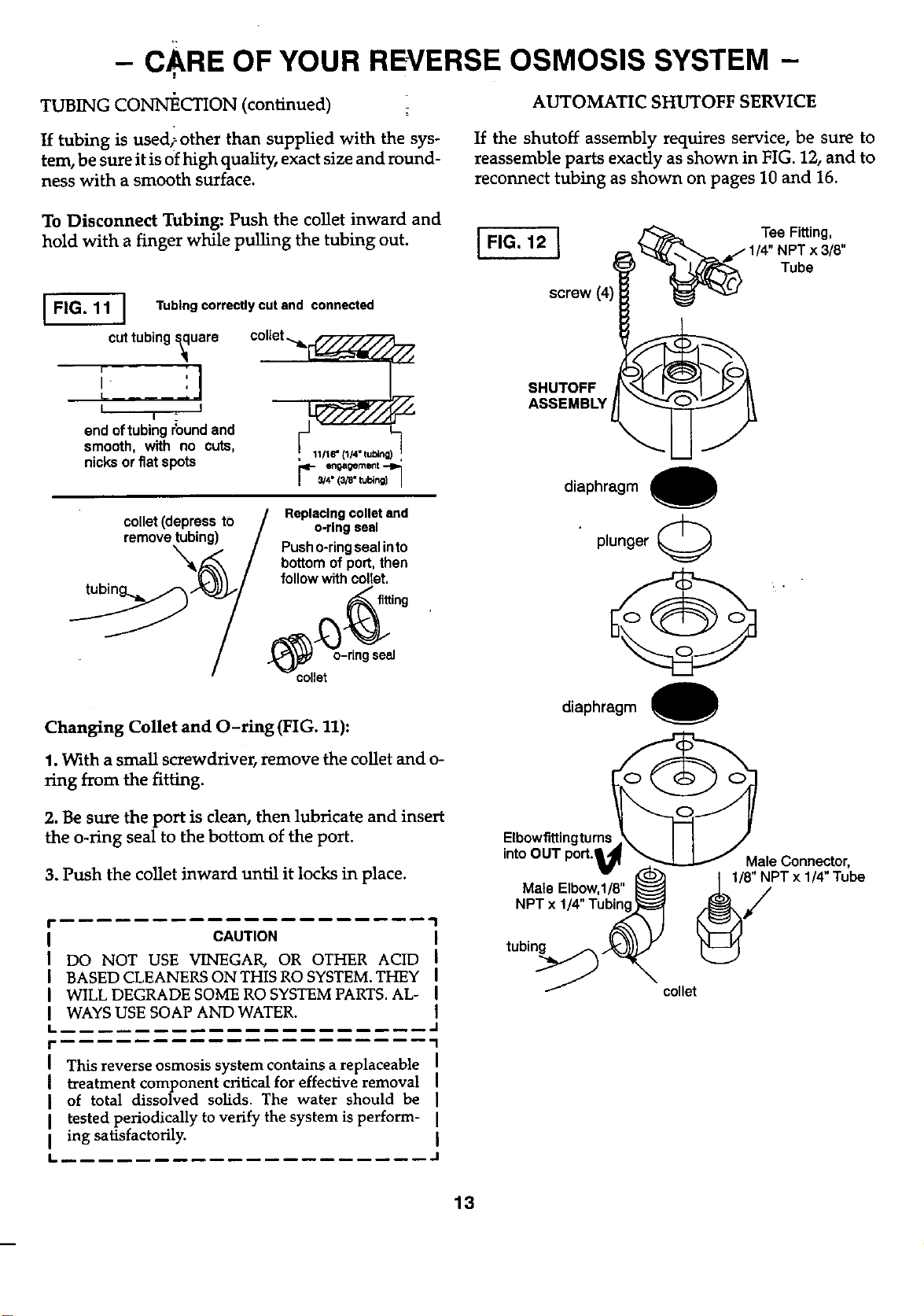

AUTOMATIC SHUTOFF SERVICE

If the shutoff assembly requires service, be sure to

reassemble parts exactly as shown in FIG. 12, and to

reconnect tubing as shown on pages 10 and 16.

To Disconnect Tubing: Push the co]let inward and

hold with a finger while pulling the tubing out.

I FIG. 11 ]

cuttubings_uare

I I

end oftubing round and

smooth, with no cuts,

nicksorflatspots

Tubing correctly cut and connected

collet .._

,_ 11/16" {1/4" tubing

engagement

r=l- 3/4. (3/_. ruling]

I,_ l_ / Replacingcolletand

co.e, \,,epress zo - • .

• / o-ring Seal

remove

,..k,,,,_,_,_,,l.,u_--/ Pusho-ringsealinto

"_,_---_k / bottomof port,then

• '_'_ / followwith collet.

tubm _ fitting

/ -g

Changing Collet and O-ring (FIG. 11):

1. With a small screwdriver, remove the coUet and o-

_ng from the fitting.

FIG. 12 I

screw (4)

1/T,eNFi._ing;8,,

__ Tube

SHUTOFF

ASSEMBLY

diaphragm O

plunger (_

@"

diaphragm 0

2. Be sure the port is clean, then lubricate and insert

the o-ring seal to the bottom of the port.

3. Push the co]let inward until it locks in place.

'1

CAUTION I

DO NOT USE VINEGAR, OR OTHER ACID

BASED CLEANERS ON THIS RO SYSTEM. THEY I

WILL DEGRADE SOME RO SYSTEM PARTS. AL- I

WAYS USE SOAP AND WATER. I

I" !

This reverse osmosis system contains a replaceable I

I treatment component critical for effective removal

of total dissolved solids. The water should be ]

I tested periodically to verify the system is perform- I

I ing satisfactorily. I

I.. ]

EIbowflttingturns

intoOUT

Mate Elbow,I/8"

NPT x 1

tubing

Male Connector,

/_iPT x 1/4"Tube

collet

13

Loading ...

Loading ...

Loading ...