Loading ...

Loading ...

Loading ...

Section 4 - REPAIR & ADJUSTMENTS

WARNING

DO NOT attempt any maintenance, adjustments or

service with engine and blade running. STOP engine

and blade. Disconnect spark plug wire and secure

away from spark plug. Engine and components are

HOT. Avoid serious burns, allow sufficient time for

all components to cool.

4.4.1. Engine Drive Belt Replacement

(Stretch Type Belts)

(Continued From Previous Page)

IMPORTANT: Drain fuel tank before tipping mower.

DO NOT tip machine with carburetor or spark plug down.

Oil from crankcase will saturate the air filter and cause the

engine to be hard to start or not start at all. If

contamination does occur, the air filter will have to be

replaced.

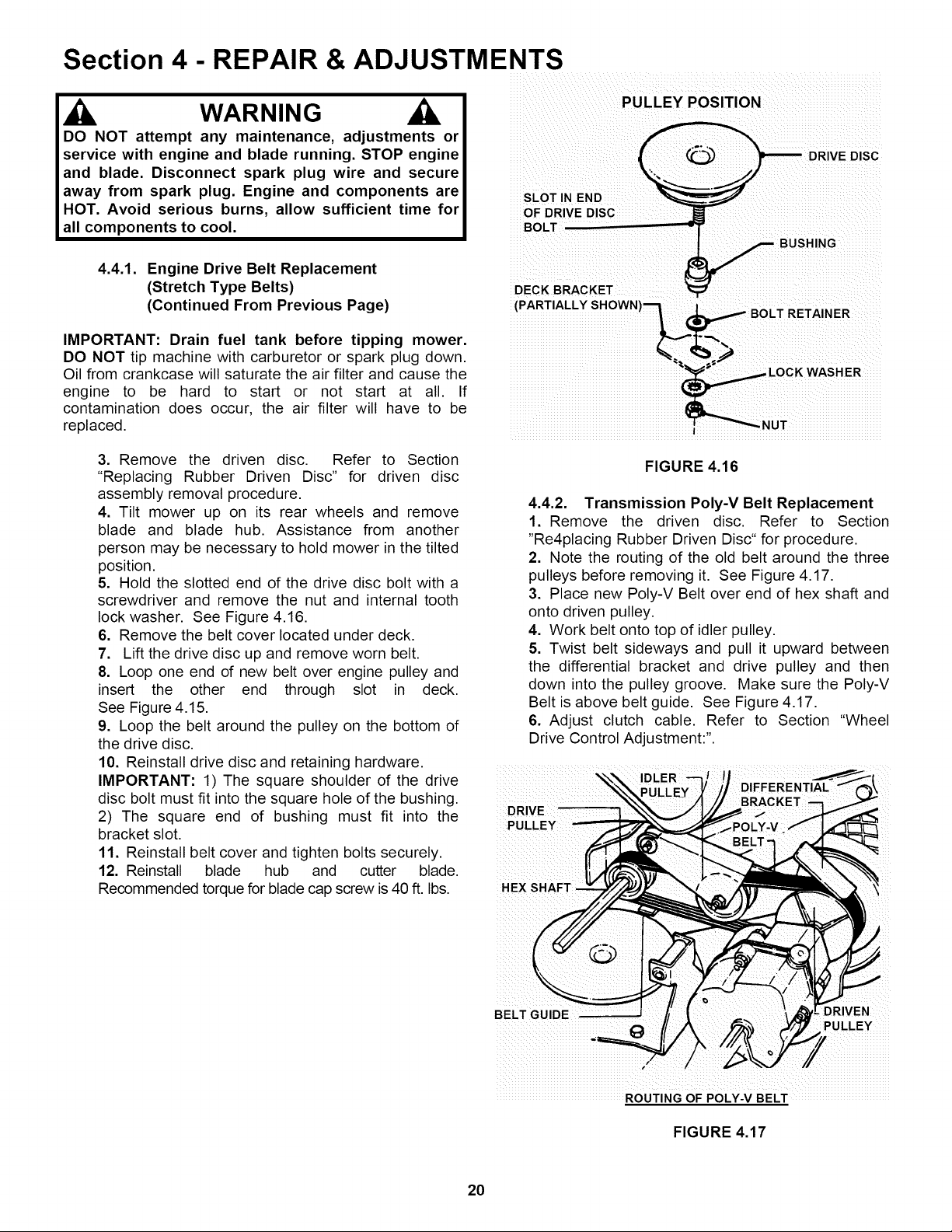

PULLEY POSITION

DRIVE DISC

SLOT IN END

OF DRI

BOLT

_-- BUSHING

DECK B

/ BOLT RETAINER

>

LOCKWASHER

3. Remove the driven disc. Refer to Section

"Replacing Rubber Driven Disc" for driven disc

assembly removal procedure.

4. Tilt mower up on its rear wheels and remove

blade and blade hub. Assistance from another

person may be necessary to hold mower in the tilted

position.

5. Hold the slotted end of the drive disc bolt with a

screwdriver and remove the nut and internal tooth

lock washer. See Figure 4.16.

6. Remove the belt cover located under deck.

7. Lift the drive disc up and remove worn belt.

8. Loop one end of new belt over engine pulley and

insert the other end through slot in deck.

See Figure 4.15.

9. Loop the belt around the pulley on the bottom of

the drive disc.

10. Reinstall drive disc and retaining hardware.

IMPORTANT: 1) The square shoulder of the drive

disc bolt must fit into the square hole of the bushing.

2) The square end of bushing must fit into the DRIVE

bracket slot.

11. Reinstall belt cover and tighten bolts securely.......................

12. Reinstall blade hub and cutter blade .............................................

Recommended torque for blade cap screw is 40 ft. Ibs.

FIGURE 4.16

4.4.2. Transmission Poly-V Belt Replacement

1. Remove the driven disc. Refer to Section

"Re4placing Rubber Driven Disc" for procedure.

2. Note the routing of the old belt around the three

pulleys before removing it. See Figure 4.17.

3. Place new Poly-V Belt over end of hex shaft and

onto driven pulley.

4. Work belt onto top of idler pulley.

5. Twist belt sideways and pull it upward between

the differential bracket and drive pulley and then

down into the pulley groove. Make sure the Poly-V

Belt is above belt guide. See Figure 4.17.

6. Adjust clutch cable. Refer to Section "Wheel

Drive Control Adjustment:".

BELT GUIDE • DRIVEN

PULLEY

.iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii ¸ ..... ...... / ...... .iiiiiiiiiiiiiiiiiiiiiiiiiii

ROUTING OF POLY-V BELT

FIGURE 4.17

2O

Loading ...

Loading ...

Loading ...