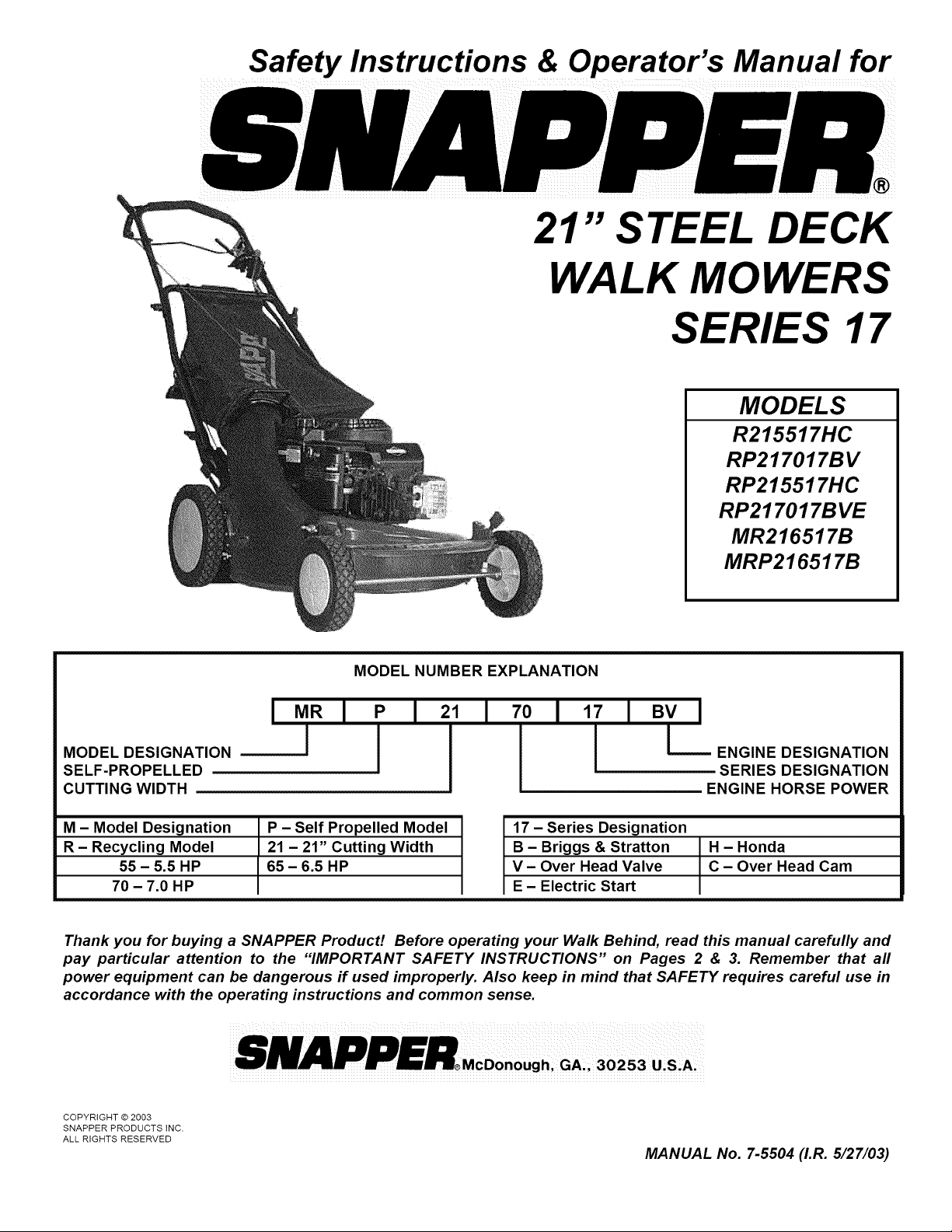

Safety Instructions & Operator's Manual for

21" STEEL DECK

WALK MOWERS

SERIES 17

MODELS

R215517HC

RP217017B V

RP215517HC

RP217017B VE

MR216517B

MRP216517B

MODEL NUMBER EXPLANATION

MODEL DESIGNATION

SELF-PROPELLED

CUTTING WIDTH

P 1211701171 Bv I

L ENGINE DESIGNATION

SERIES DESIGNATION

ENGINE HORSE POWER

M - Model Designation

R - Recycling Model

55 - 5.5 HP

70 - 7.0 HP

P - Self Propelled Model

21 - 21" Cutting Width

65 - 6.5 HP

17 - Series Designation

B - Briggs & Stratton

V- Over Head Valve

E - Electric Start

H - Honda

C - Over Head Cam

Thank you for buying a SNAPPER Product! Before operating your Walk Behind, read this manual carefully and

pay particular attention to the "IMPORTANT SAFETY INSTRUCTIONS" on Pages 2 & 3. Remember that all

power equipment can be dangerous if used improperly. Also keep in mind that SAFETY requires careful use in

accordance with the operating instructions and common sense.

gh, GA:, 30253 U.S:A:

COPYRIGHT © 2003

SNAPPER PRODUCTS iNC.

ALL RIGHTS RESERVED

MANUAL No. 7-5504 (I.R. 5/27/03)

Loading ...

Loading ...

Loading ...