Loading ...

INSTALLATION MANUAL

CAUTION INDICATES A POTENTIALLY HAZARDOUS

SITUATION WHICH, IF NOT AVOIDED, MAY RESULT

IN MINOR OR MODERATE INJURY.

TO REDUCE THE RISK OF HAZARDS THAT

CAN CAUSE INJURY OR PROPERTY DAMAGE,

OBSERVE THE FOLLOWING WARNINGS:

IF THIS PUMP CONTAINS A SWITCH FOR AUTOMATIC

OPERATION, IT IS THE INSTALLER’S RESPONSIBILITY

TO MAKE SURE THE SWITCH IS ABLE TO OPERATE

WITHOUT ANY OBSTRUCTIONS WITHIN THE BASIN. It is

recommended that the installer test and observe the pump’s

operation for several cycles after installation.

IT IS RECOMMENDED TO USE RIGID PIPING AND

FITTINGS to secure the pump in the basin and reduce pump

movement. Pump movement can prevent the switch from

operating correctly.

THIS PUMP SHOULD BE INSPECTED 3 TO 4 TIMES PER

YEAR for pump movement or buildup of debris on the switch or

fl oat. Reposition pump if it has moved. Remove any debris that

could interfere with the operation of the switch.

2

IT IS RECOMMENDED TO USE A CHECK VALVE with this

pump to prevent the back-fl ow of fl uid after each pump cycle.

DO NOT INSTALL OR OPERATE THE PUMP IF IT HAS

BEEN DAMAGED IN ANY WAY.

DO NOT LIFT OR CARRY THE PUMP BY THE POWER

CORD. Use the pump’s handle.

DO NOT USE THIS PUMP IN MUD, SAND, CEMENT, OIL

OR CHEMICALS.

DO NOT USE SUMP AND EFFLUENT PUMPS TO HANDLE

RAW SEWAGE.

AN INDEPENDENT HIGH WATER ALARM OR BACK UP

PUMP SHOULD BE USED when risk of property damage from

high water levels exists

THE SWITCH SHOULD BE REPLACED EVERY TWO (2)

YEARS. This maintenance will reduce the risk of improper

pump operation, switch failure, or fl ooding.

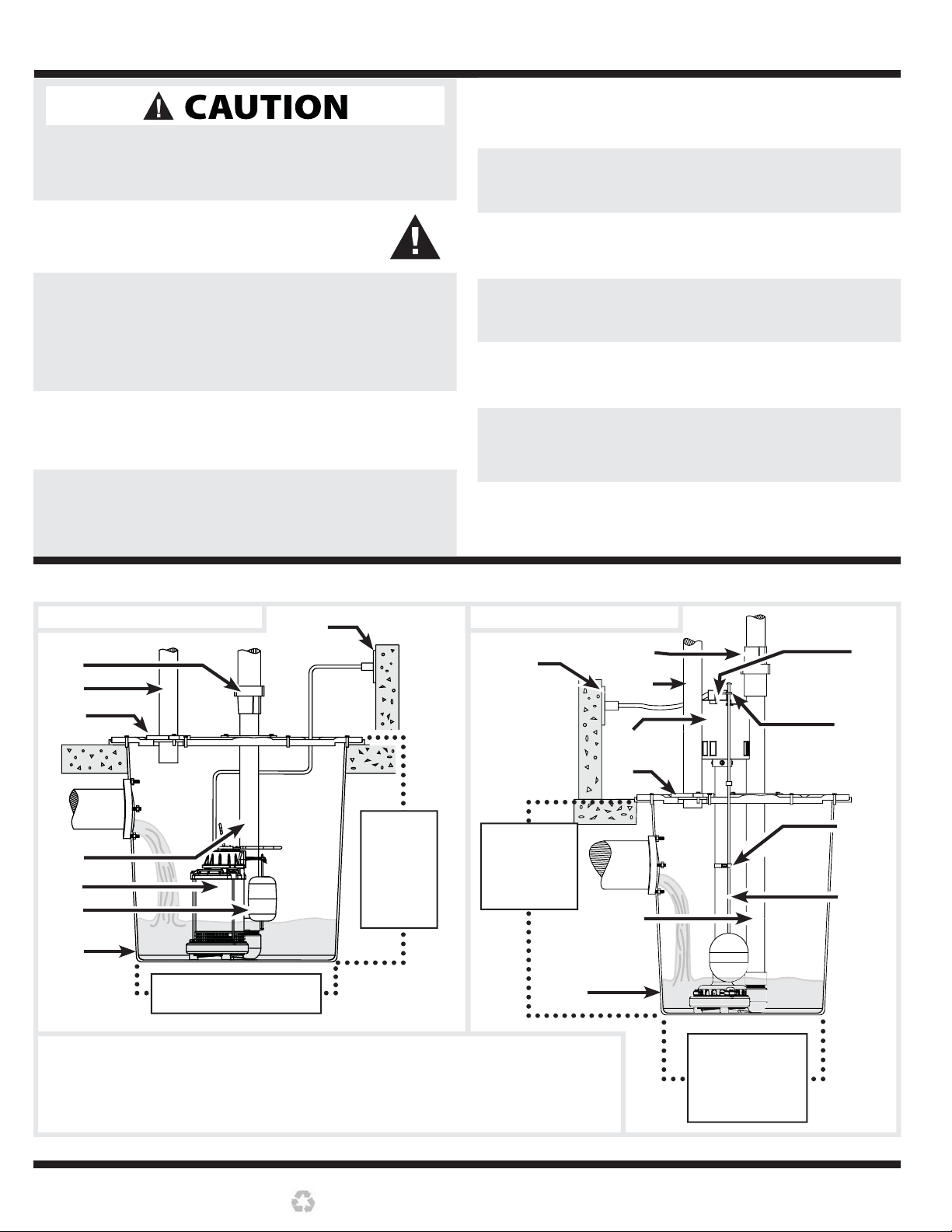

Figure 1: Submersible Sump

Figure 2: Pedestal Sump

1

2

3

5

8

9

7

6

1. GFCI OUTLET 5. PIPE INLET 9. SUMP BASIN

2. CHECK VALVE 6. DISCHARGE PIPE 10. FLOAT ROD

3. VENT PIPE 7. SUMP PUMP 11. FLOAT GUIDE

4. GASKET/BASIN LID 8. SWITCH (SEE CHART A, ON PAGE 3) 12. SWITCH ARM

MINIMUM

BASIN

HEIGHT

(SEE

CHART A,

COLUMN B)

MINIMUM BASIN DIAMETER

(SEE CHART A, COLUMN A)

4

MAXIMUM

BASIN HEIGHT

(SEE CHART B,

COLUMN B)

MINIMUM BASIN

DIAMETER

(SEE CHART B,

COLUMN A)

8

6

2

3

7

9

11

5

12

10

4

TYPICAL SUMP INSTALLATION DIAGRAMS

Printed on 100% Recycled Paper

1

Loading ...

Loading ...

Loading ...