Loading ...

Loading ...

Loading ...

ALLURE + QS3 SERmES

RANGE HOOD

®

Page 4

PREPARE THE HOOD PREPARE THE HOOD

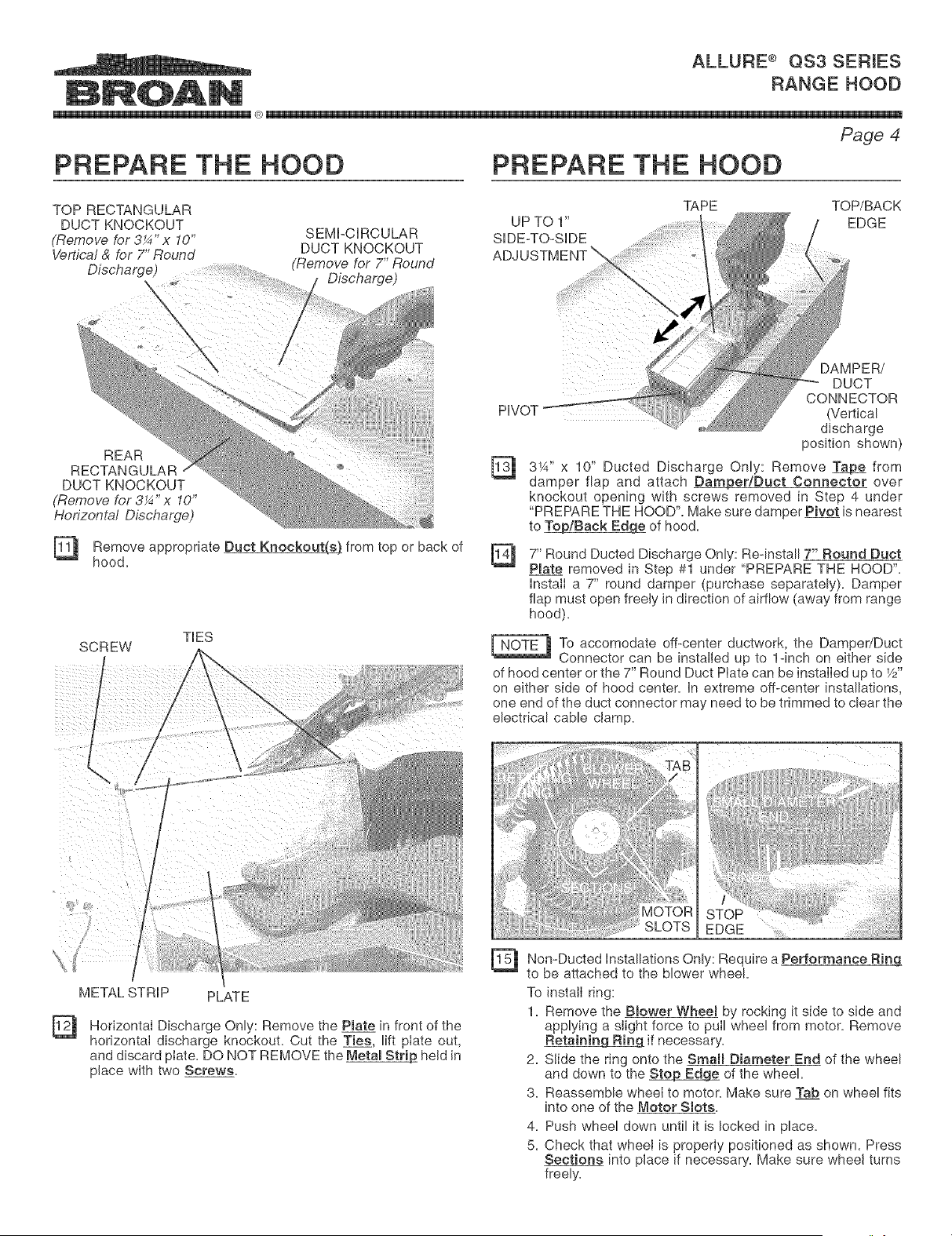

TOP RECTANGULAR TAPE TOP/BACK

DUCT KNOCKOUT UP TO 1" EDGE

(Remove for 3¼" x 10" SEMI+CIRCULAR SDE-TO-SDE

Vertical & for 7" Round DUCT KNOCKOUT

Discharge) (Remove for 7" Round

Discharge)

HVOT

REAR

RECTANGULAR

DUCT KNOCKOUT

(Remove for 3¼" x 10"

Horizontal Discharge)

[_ Remove appropriate Duct Knockouts(A). from or back of

hood. top [_

SCREW

/

/

/

TES

l

/

t

/

/

"--. /

/

METAL STRIP PLATE

Horizontal Discharge Only: Remove the Pmatein front of the

horizontal discharge knockout. Cut the Ties, lift plate out,

and discard plate. DO NOT REMOVE the Metal Strip held in

place with two Screws.

DAMPER/

DUCT

CONNECTOR

(Vertical

discharge

position shown)

3¼" x 10" Ducted Discharge Only: Remove _ from

damper flap and attach Damper/Duct Connector over

knockout opening with screws removed in Step 4 under

"PREPARE THE HOOD". Make sure damper Pivot is nearest

to B/Back Edge of hood.

7" Round Ducted Discharge Only: Re-install 7" Round Duct

Plate removed in Step #1 under "PREPARE THE HOOD".

InstalI a 7" round damper (purchase separately). Damper

flap must open freely in direction of airflow (away from range

hood).

_To accomodate off-center ductwork, the Damper/Duct

Connector can be installed up to 1-inch on either side

of hood center or the 7" Round Duct Plate can be installed up to _/z"

on either side of hood center. In extreme off-center installations,

one end of the duct connector may need to be trimmed to clear the

electrical cable clamp.

SLOTS EDGE ....

[1_ Non-Ducted Installations Only: Require a Performance Ring

to be attached to the blower wheel.

To install ring:

1. Remove the Blower WheeB by rocking it side to side and

applying a slight force to pull wheel from motor. Remove

Retainin_ if necessary.

2. Slide the ring onto the Small Diameter End of the wheel

and down to the _ of the wheel.

3. Reassemble wheel to motor. Make sure Tab on wheel fits

into one of the Motor Slots.

4. Push wheel down until it is locked in place.

5. Check that wheel is properly positioned as shown. Press

Sections into place if necessary. Make sure wheel turns

freely.

Loading ...

Loading ...

Loading ...