Loading ...

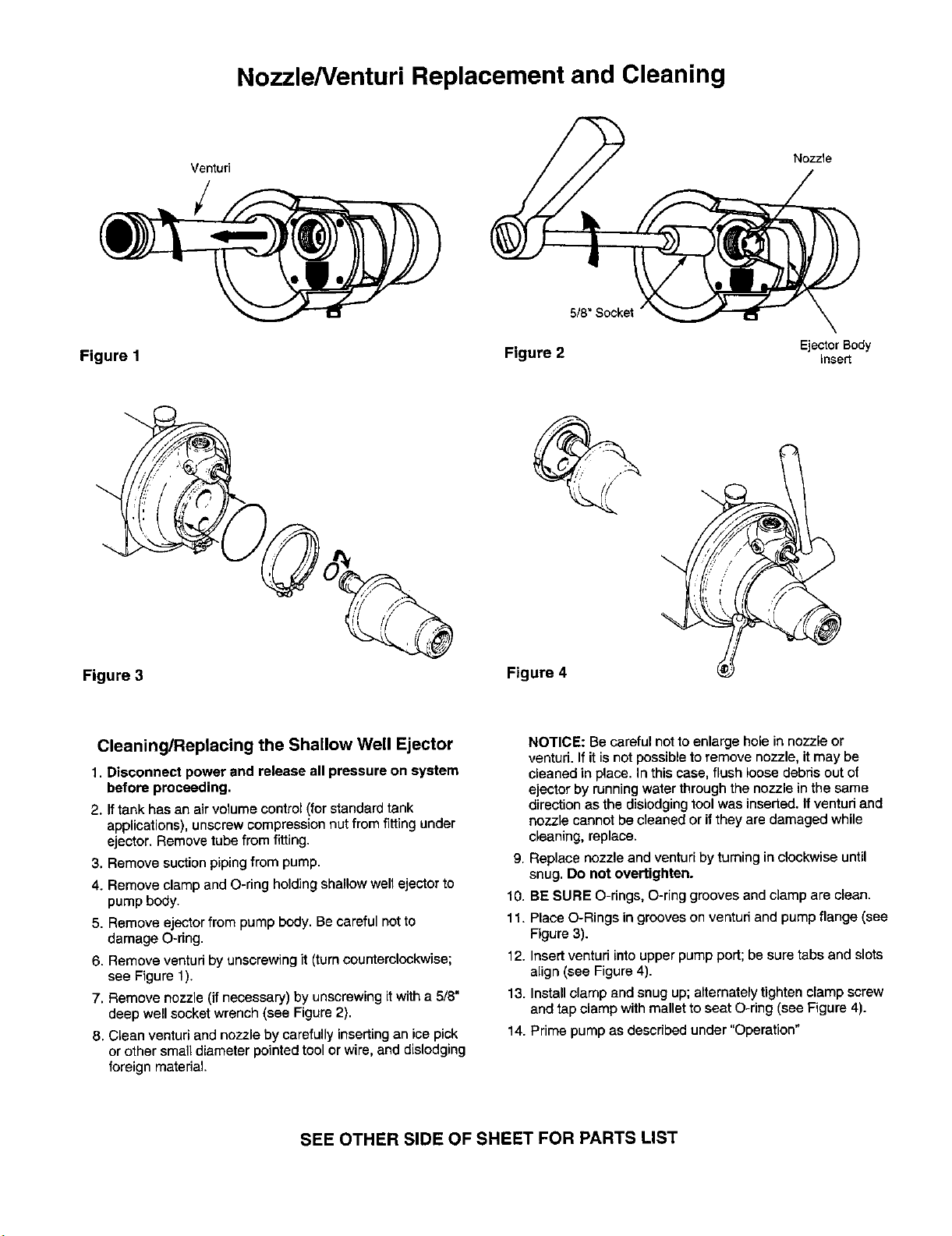

Nozzle/Venturi Replacement and Cleaning

Venturi

5/8" Socket

Nozzle

Figure 1

Ejector Body

Figure 2 insert

Figure 3

Figure 4

Cleaning/Replacing the Shallow Well Ejector

1. Disconnect power and release all pressure on system

before proceeding.

2. Iftank has an air volume control (for standard tank

applications), unscrew compression nut from fitting under

ejector. Remove tube from fitting.

3, Remove suction pipingfrom pump.

4. Remove clamp and O-ring holdingshallow well ejector to

pump body.

5. Remove ejector from pump body. Be careful not to

damage O-ring.

6. Remove ventud by unscrewing it (turnoountemlockwise;

see Figure 1).

7, Remove nozzle (ifnecessary) by unscrewing it with a 5/8"

deep well socket wrench (see Figure 2).

8, Clean venturi and nozzle by carefully inserting an ice pick

or other small diameter pointed tool or wire, and dislodging

foreign material

NOTICE: Be careful not to enlarge hole in nozzle or

venturi. If itis not possible to remove nozzle, it may be

cleaned in place. In this case, flush loose debris out of

ejector by running water through the nozzle in the same

direction as the dislodging tool was inserted. If venturi and

nozzle cannot be cleaned or if they are damaged while

cleaning, replace.

9. Replace nozzle and venturi by turning in clockwise until

snug. Do not overtighten.

10. BE SURE O-rings, O-ring grooves and clamp are clean.

11. Place O-Rings in grooves on venturi and pump flange (see

Figure 3).

12. Insert venturi into upper pump port; be sure tabs and slots

align (see Figure 4).

13. Install clamp and snug up; alternately tighten clamp screw

and tap clamp with mallet to seat O-ring (see Figure 4).

14. Prime pump as described under "Operation"

SEE OTHER SIDE OF SHEET FOR PARTS LIST

Loading ...