Loading ...

Loading ...

Loading ...

English

— 10 —

APPLICATIONS

Air compressors are utilized in a variety of air system

applications.

Match hoses, connectors, air tools, and accessories to the

capabilities of the air compressor.

You may use this tool for purposes listed below:

Operating air powered tools requiring less than 2.8 SCFM @ 90

PSI or 3.7 SCFM @ 40 PSI.

Powering pneumatic nail guns, infl ating tires, cleaning / blowing

with pressurized air.

WARNING:

Always follow all safety rules

recommended by the manufacturer of

your tool, in addition to all safety rules

for the air compressor.

Following these rules will reduce the

risk of serious personal injury.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms to

the power source requirements specifi ed on the product

nameplate.

NOTE: If compressor is connected to a circuit protected by

fuse, use time delay fuses.

Time delay fuses should be marked “D” in Canada and

“T” in the U.S.

2. Power switch

Ensure that the knob of the pressure switch is in the “OFF”

position (Fig. 2). If the plug is connected to a receptacle

while the knob is in the “ON” position, the compressor will

start operating immediately and can cause serious injury.

ON

OFF

Knob of the

pressure switch

Fig. 2

3. Extension cord

When the work area is far away from the power source,

use an extension cord of suffi cient thickness and rated

capacity (refer page 7). The extension cord should be kept

as short as practicable.

WARNING: Damaged cord must be replaced or

repaired.

4. Confi rm the power receptacle

If the power receptacle only loosely accepts the plug, the

receptacle must be repaired. Contact the nearest electric

store for repair service.

If such a faulty receptacle is used, may cause overheating,

resulting in a serious hazard.

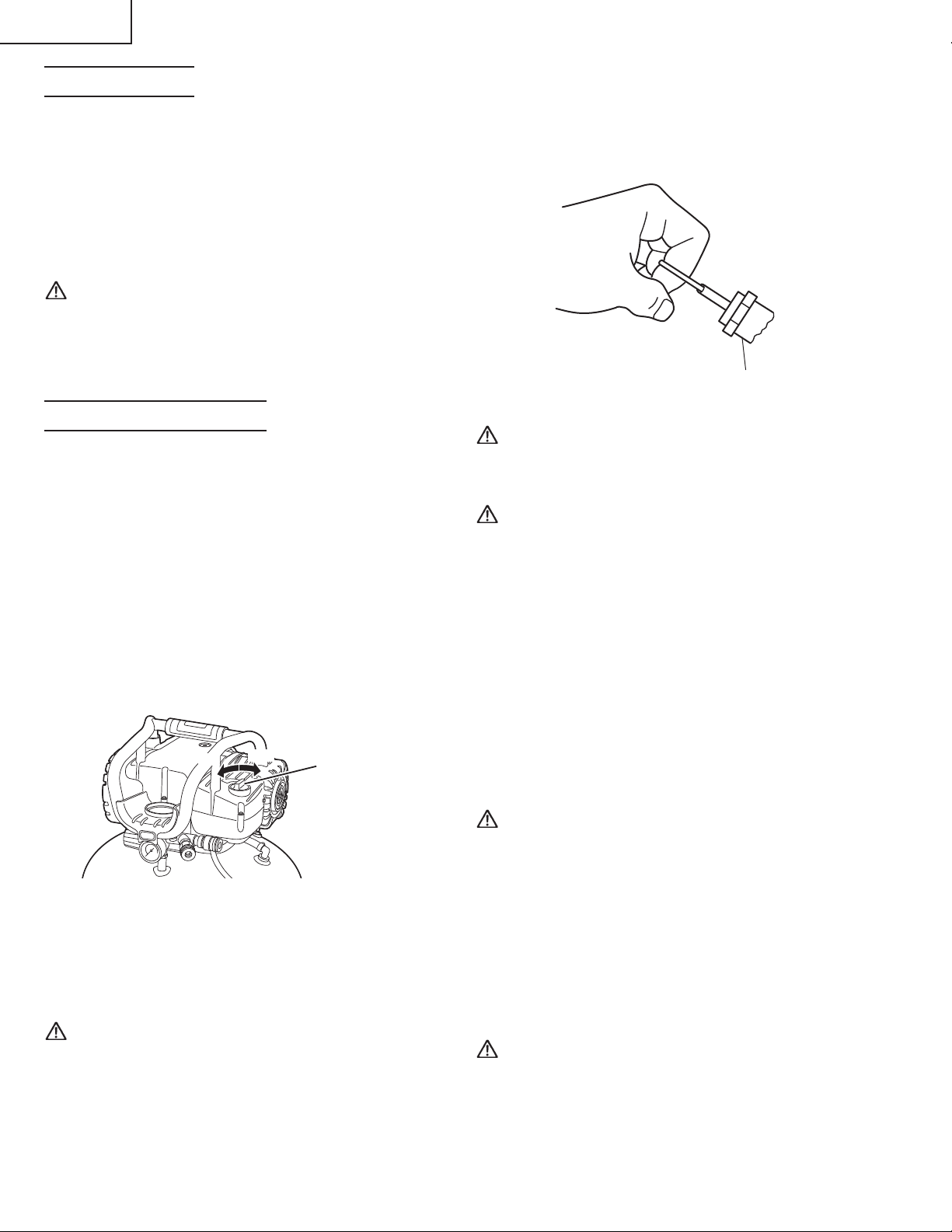

5. To check the safety valve.

Before starting compressor, pull the ring on the safety

valve to make sure that the safety valve operates smoothly.

(Fig. 3) Do not use compressor if the safety valve is stuck

or does not operate smoothly. Have defective safety valve

replaced by a metabo HPT authorized service center.

Safety valve

Fig. 3

WARNING: Drain tank to release air pressure

before pull the ring on the safety

valve.

WARNING: Risk of bursting.

If the safety valve does not work

properly, over-pressurization may

occur, causing air tank rupture or an

explosion.

6. Right running position

Always operate the compressor in a stable and secure

position to prevent accidental movement of the unit.

Never operate the compressor on a roof or other elevated

positon. Never use on a ladder or unstable support. Use an

additional air hose to reach high locations.

Operate the compressor in an open area at least 18 in.

away from any wall or object that could restrict the fl ow of

fresh air to the ventilation openings. Do not place rags or

other objects on or near these openings.

WARNING: A portable compressor can fall from

a table, workbench, or roof causing

damage to the compressor and could

result in serious injury or death to the

operator.

NOTE: When operating or storing the copmressor, set 4 rubber

bumpers downward on the fl oor (Refer to Fig. 1)

7. Temperature

Operating temperatures are between 32°F and 104°F

(0°C and 40°C).

CAUTION: Never operate in temperatures below 32°F

(0°C) or above 104°F (40°C).

8. Air hose

Check the air hose for weak or worn condition before each

use, making certain all connections are secure. Do not use

it if a defect is found. Purchase a new air hose or notify a

metabo HPT authorized service center for examination or

repair.

000BookEC710Smetabo.indb10000BookEC710Smetabo.indb10 2018/03/158:27:482018/03/158:27:48

Loading ...

Loading ...

Loading ...