Loading ...

Loading ...

Loading ...

TRANSPORTING YOUR TILLER

AROUND THE YARD

• Pull forward on lift handle until it locks in the up,

transport position.

AROUND TOWN

Disconnect spark plug wire.

Drain fuel tank.

Transport in upright position to prevent oil leakage.

TO ADJUST DEPTH STAKE

• Depth stake has five position holes to select tilling

depth from 1 to 5 inches.

• The top stake hole selects the shallowest tilling

depth and the bottom stake hole selects the deepest

position.

• To change depth, remove the hair cotter pin from the

clevis pin which is connecting the depth stake to the

stake support bracket.

• Grasp the top of the depth stake, remove the clevis

pin and reposition the depth stake. Insert clevis pin

and hair cotter pin.

IMPORTANT: THE DEPTH STAKE SHOULD NEVER

BE REMOVED FROM THE TILLER. IT IS DESIGNED

TO PROTECT THE TRACTOR TRANSAXLE FROM

THRUSTING ACTION OF THE TILLER.

TiLLiNG

The most efficient tillage is obtained when tiller

engine is operated at full throttle. The sound of the

tiller engine will tell you. When tiller engine is lightly

loaded, raise gauge wheels to increase tilling depth.

If engine seems to be overloaded or stalls out, lower

gauge wheels for shallower tilling.

Operate tiller engine at full throttle and operate

tractor in slowest forward speed with tractor engine

at idle speed or just above idle.You will soon learn

the proper combination of tilling depth and speed for

good tillage.

Soil conditions will determine how deep tiller can

penetrate on the first pass. In extremely hard ground,

several passes may be necessary to till to a depth of

6 inches. While in soft ground, tiller may penetrate to

a depth of 6 inches in the first pass.

TiLLiNG HINTS

IMPORTANT OPERATING HINTS

NOTE: The following is a general guideline of tilling, but

may vary depending upon soil conditions.

In virgin soil, tiller should be started in shallowest

depth position and lowered one position at a time

after each pass in each direction.

If the soil is extremely hard and dry, it may be

desirable to cross till an area at shallow depth first,

then till in the direction of planting rows on the second

pass at the final depth.

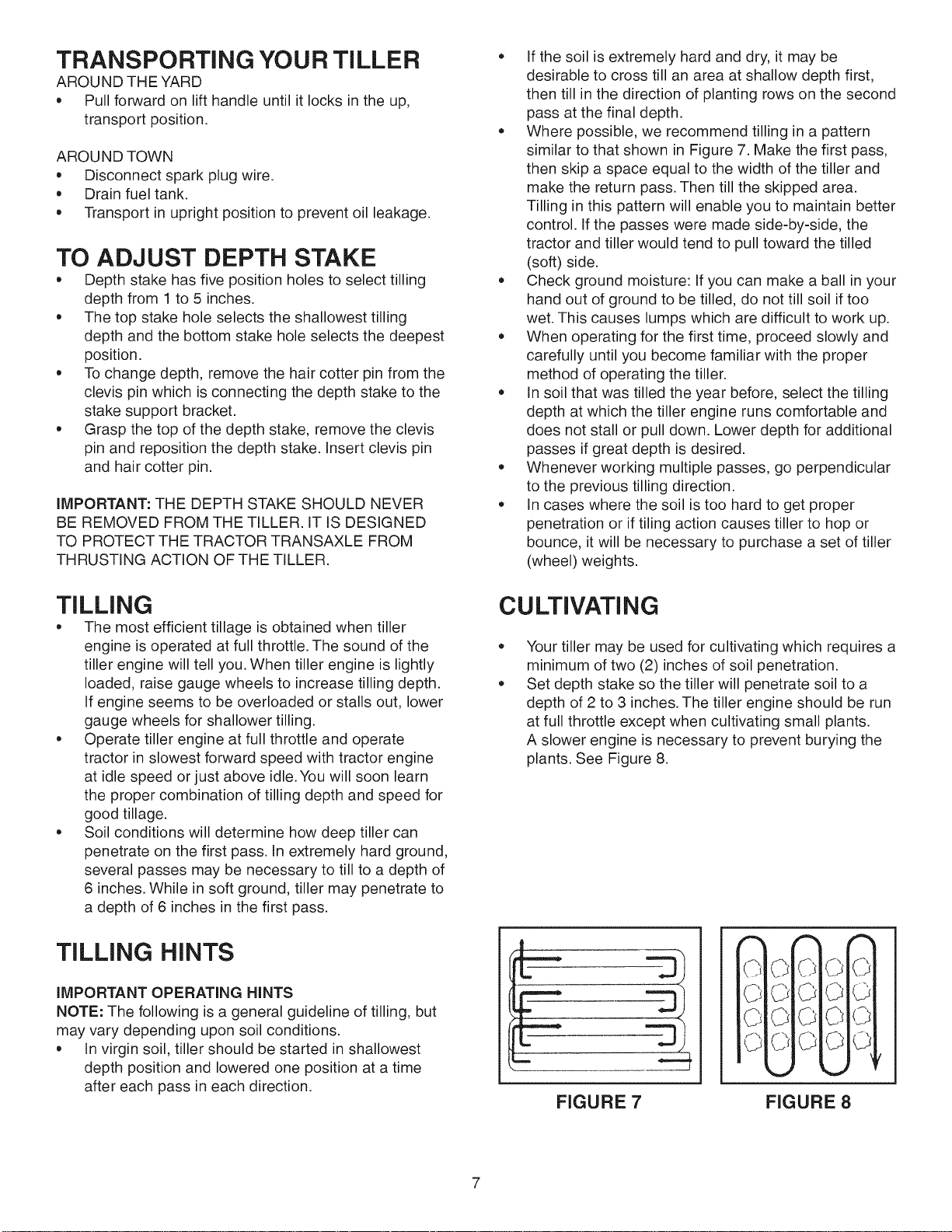

Where possible, we recommend tilling in a pattern

similar to that shown in Figure 7. Make the first pass,

then skip a space equal to the width of the tiller and

make the return pass. Then till the skipped area.

Tilling in this pattern will enable you to maintain better

control. If the passes were made side-by-side, the

tractor and tiller would tend to pull toward the tilled

(soft) side.

Check ground moisture: If you can make a ball in your

hand out of ground to be tilled, do not till soil if too

wet. This causes lumps which are difficult to work up.

When operating for the first time, proceed slowly and

carefully until you become familiar with the proper

method of operating the tiller.

In soil that was tilled the year before, select the tilling

depth at which the tiller engine runs comfortable and

does not stall or pull down. Lower depth for additional

passes if great depth is desired.

Whenever working multiple passes, go perpendicular

to the previous tilling direction.

In cases where the soil is too hard to get proper

penetration or if tiling action causes tiller to hop or

bounce, it will be necessary to purchase a set of tiller

(wheel) weights.

CULTIVATING

o

o

Your tiller may be used for cultivating which requires a

minimum of two (2) inches of soil penetration.

Set depth stake so the tiller will penetrate soil to a

depth of 2 to 3 inches. The tiller engine should be run

at full throttle except when cultivating small plants.

A slower engine is necessary to prevent burying the

plants. See Figure 8.

i-

ra

-- -5

m

u

FIGURE 7

OCOOO

OCOOO

OCOO<P

OCOOO

FIGURE 8

Loading ...

Loading ...

Loading ...