Loading ...

Loading ...

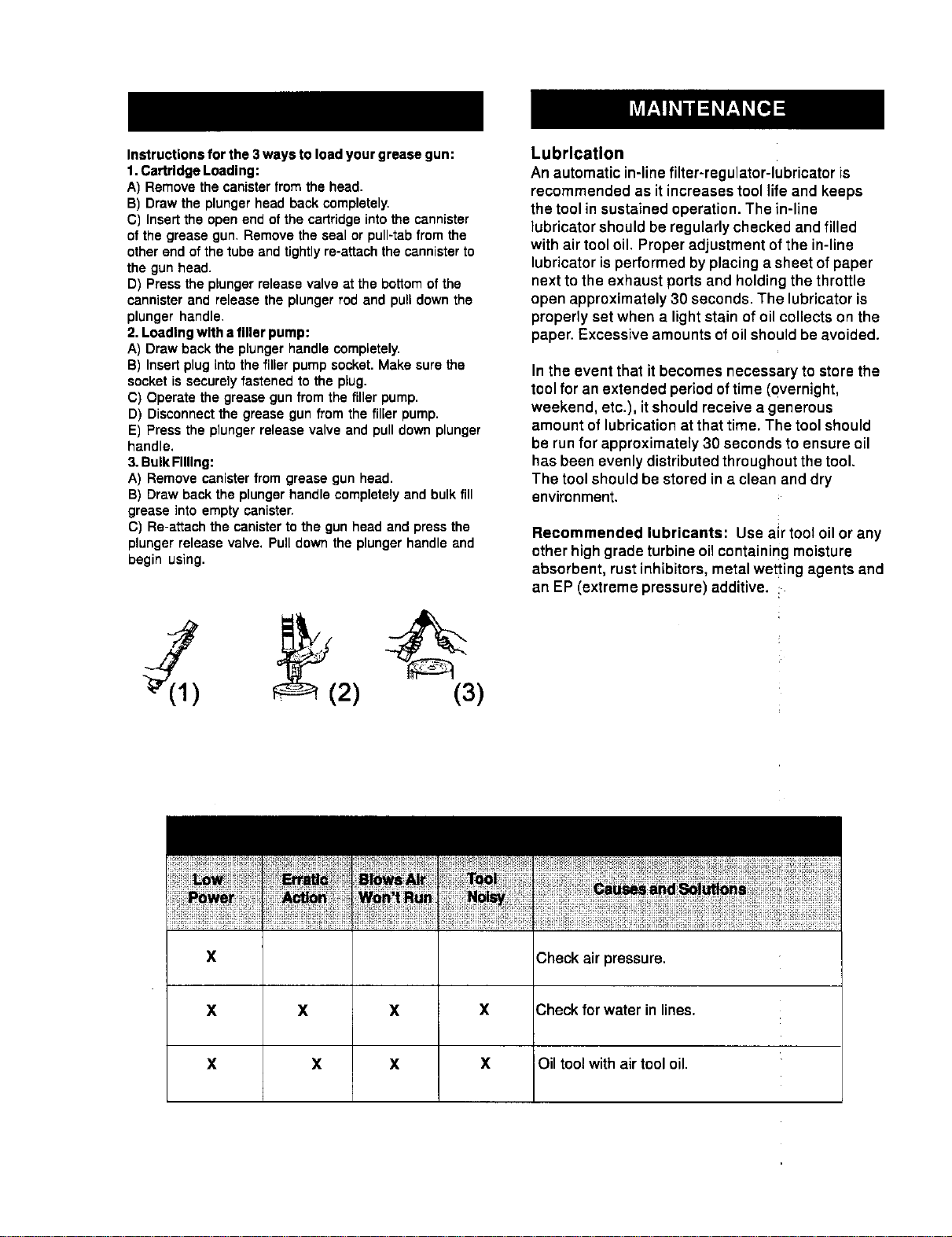

Instructions for the 3 ways to load your grease gun:

1,Cartridge Loading:

A) Remove the canister from the head,

B) Draw the plunger head back completely,

C) Insert the open end of the cartridge intothe cannister

of the grease gun. Remove the seal or pull-tab from the

other end of the tube and tightly re-attach the cannister to

the gun head.

D) Press the plunger release valve at the bottom of the

cannister and release the plunger rod and pull down the

plunger handle.

2. Loading with afiller pump:

A) Draw back the plunger handle completely,

B) Insert plug intothe filler pump socket, Make sure the

socket is securely fastened to the plug,

C) Operate the grease gun from the filler pump,

D) Disconnect the grease gun from the filler pump,

E) Press the plunger release valve and pull down plunger

handle,

3. Bulk Filling:

A) Remove canister from grease gun head.

B) Draw back the plungerhandle completely and bulk fill

grease into empty canister.

C) Re-attach the canister to the gun head and press the

plunger release valve. Pull down the plunger handle and

begin using.

Lubrication

An automatic in-linefilter-regulator-lubricator is

recommended as it increases tool life and keeps

the tool in sustained operation. The in-line

lubricator should be regularly checked and filled

with air tooloil. Proper adjustment of the in-line

lubricatorisperformed by placinga sheet ofpaper

nextto the exhaust portsand holdingthe throttle

open approximately 30 seconds. The lubricatoris

properly set when a light stain of oil collects on the

paper. Excessive amounts of oilshould be avoided.

In the event that it becomes necessary to store the

tool for an extended periodoftime (overnight,

weekend, etc.), itshould receive a generous

amount of lubrication at that time. The tool should

be runfor approximately 30 seconds to ensure oil

has been evenly distributedthroughout the tool.

The tool should be stored in a clean and dry

environment.

Recommended lubricants: Use air tool oil or any

other high grade turbine oilcontaining moisture

absorbent, rust inhibitors,metal wetting agents and

an EP (extreme pressure) additive.

X Check air pressure.

X X X X Check for water in lines.

X X X X Oil toolwith air tooloil.

Loading ...

Loading ...

Loading ...