Loading ...

Loading ...

Loading ...

CheckSpray Gunand NozzleExtension

Examinehoseconnectionto spraygun and makesure it is

secure.Testtrigger by pressingit and makingsure it springs

backinto placewhenyou releaseit. Do not depressredbutton

andtest trigger.You should not beableto presstrigger. Replace

spraygun immediatelyif it fails anyof thesetests.

Selector Nozzle Maintenance

A pulsing sensation felt while squeezingthe spray gun trigger

may be causedby excessive pump pressure. The principal

causeof excessive pump pressure is a nozzle clogged or

restricted with foreign materials, such as dirt, etc. To correct

the problem, immediately clean the nozzlesfollowing these

instructions:

1. Shut off engine and turn off water supply.

2. ALWAYSpoint spray gun in a safe direction, press red

button and and squeezespray gun trigger to release

retained high water pressure.

_lLWARNING The high pressure stream of water that

this equipment produces can cut through skin

and its underlying tissues, leadingto serious

injury and possible amputation.

Spray gun traps high water pressure, even when engine is

stopped and water is disconnected, which can cause

injury.

* Keephighpressurehoseconnectedto pumpandspraygun

whilesystemis pressurized.

* ALWAYSpointspraygun in safedirection,pressred button

andsqueezesprayguntriggerto releasehighpressure,every

timeyou stopengine.

.

4.

.

6.

Remove selector nozzlefrom end of nozzleextension.

Use a small paper clip to free any foreign material

clogging or restricting each nozzle(A) in the selector

nozzle.

Remove nozzleextension from spray gun.

Using a garden hose, remove additional debris by back

flushing water through nozzleextension. Backflush

between 30 to 60 seconds.

7. Reinstall selector nozzleinto nozzleextension.

8. Reconnect nozzleextension to spray gun.

9. Make sure garden hose is connected to water inlet.

Checkthat high pressure hose is connected to spray gun

and pump. Turn on water.

10. Start enginefollowing instructions How to Start Your

Pressure Washer.

11. Test pressurewasher by operating in each spray pattern.

O-Ring Maintenance

Purchasean O-Ring RepairKit at your local Searsor by calling

1-800-4-1VlY-HOIVlE(469-4663) or online at www.sears.com, it

is not includedwith the pressurewasher.This kit includes

replacemento-rings, rubberwasherandwater inletfilter. Referto

the instructionsheetprovidedin the kit to serviceyour unit's

o-rings.

A. WARNING The high pressure stream of water that

this equipment produces can cut through skin

and its underlying tissues, leading to serious

injury and possible amputation.

* NEVERrepairleakingconnectionswithsealantof any kind.

Replaceo-ringor seal.

ENGINEMAINTENANCE

A. WARNING Unintentional sparking can result in fire or

_¢ electric shock.

WHENADJUSTINGOR MAKING REPAIRSTOYOUR PRESSURE

WASHER

* Disconnect the spark plug wire from the spark plug and place

the wire where it cannot contact spark plug.

WHENTESTINGFOR ENGINESPARK

* Useapproved spark plug tester.

* DONOT check for spark with spark plug removed.

Oil

Oil Recommendations

We recommend the use of Briggs & Stratton Warranty

Certified oils for best performance. Other high-quality

detergent oils are acceptable if classified for service SF,SG,

SH,SJ or higher. DO NOTuse special additives.

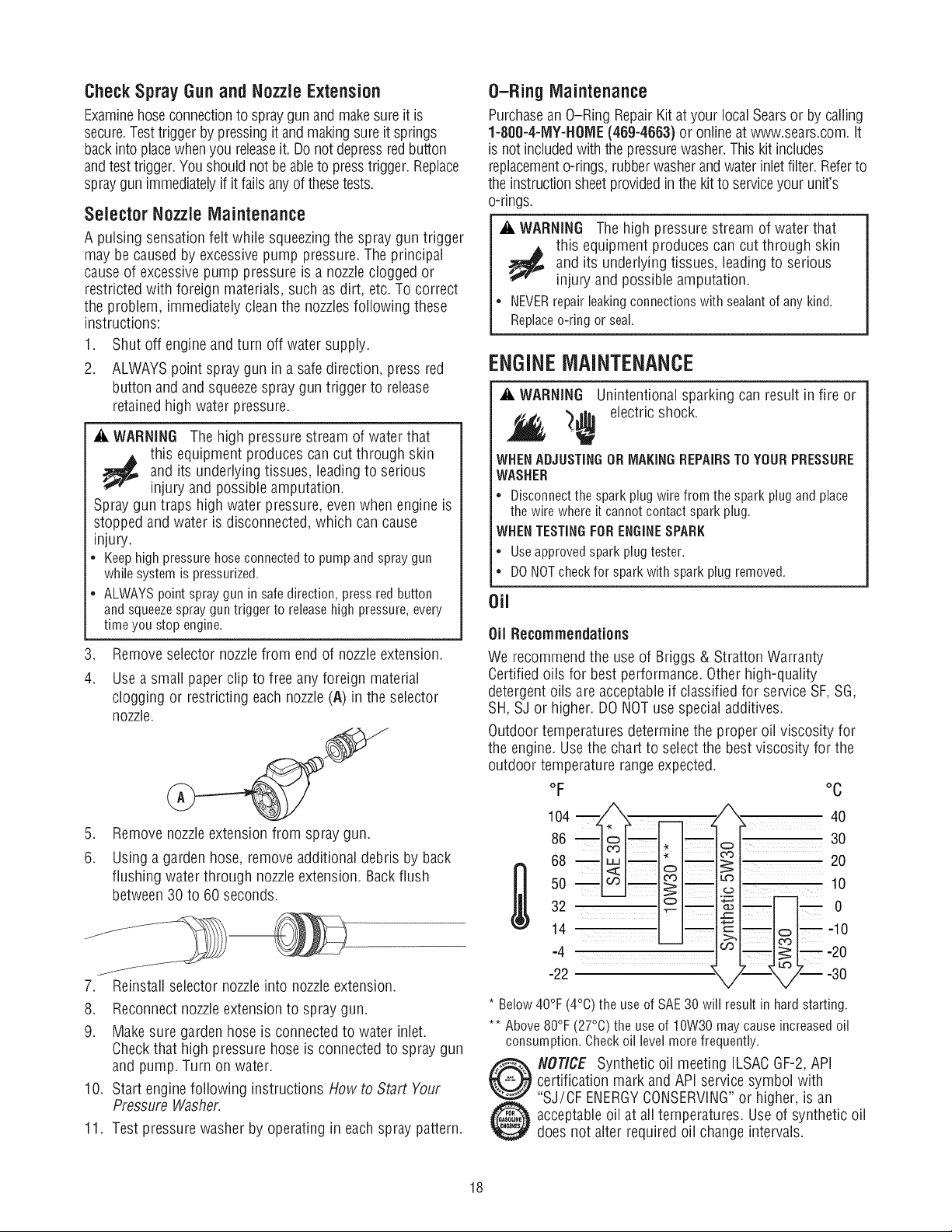

Outdoor temperatures determine the proper oil viscosity for

the engine. Usethe chart to select the best viscosity for the

outdoor temperature range expected.

oF

104___506886 _coo__

32 .o

14

-4

-22

oc

\ 40

;_30

_°_20

10

_m m 0

--_C °

-20

-30

* Below40°F(4°C)the useof SAE30will resultin hardstarting.

** Above80°F(27°C)the useof 10W30maycauseincreasedoil

consumption.Checkoil levelmorefrequently.

NOTICE Synthetic oil meeting ILSACGF-2,API

certification mark and API service symbol with

"SJ/0F ENERGYCONSERVING"or higher, is an

acceptable oil at all temperatures. Useof synthetic oil

does not alter required oil change intervals.

18

Loading ...

Loading ...

Loading ...