Loading ...

Loading ...

Loading ...

page 7

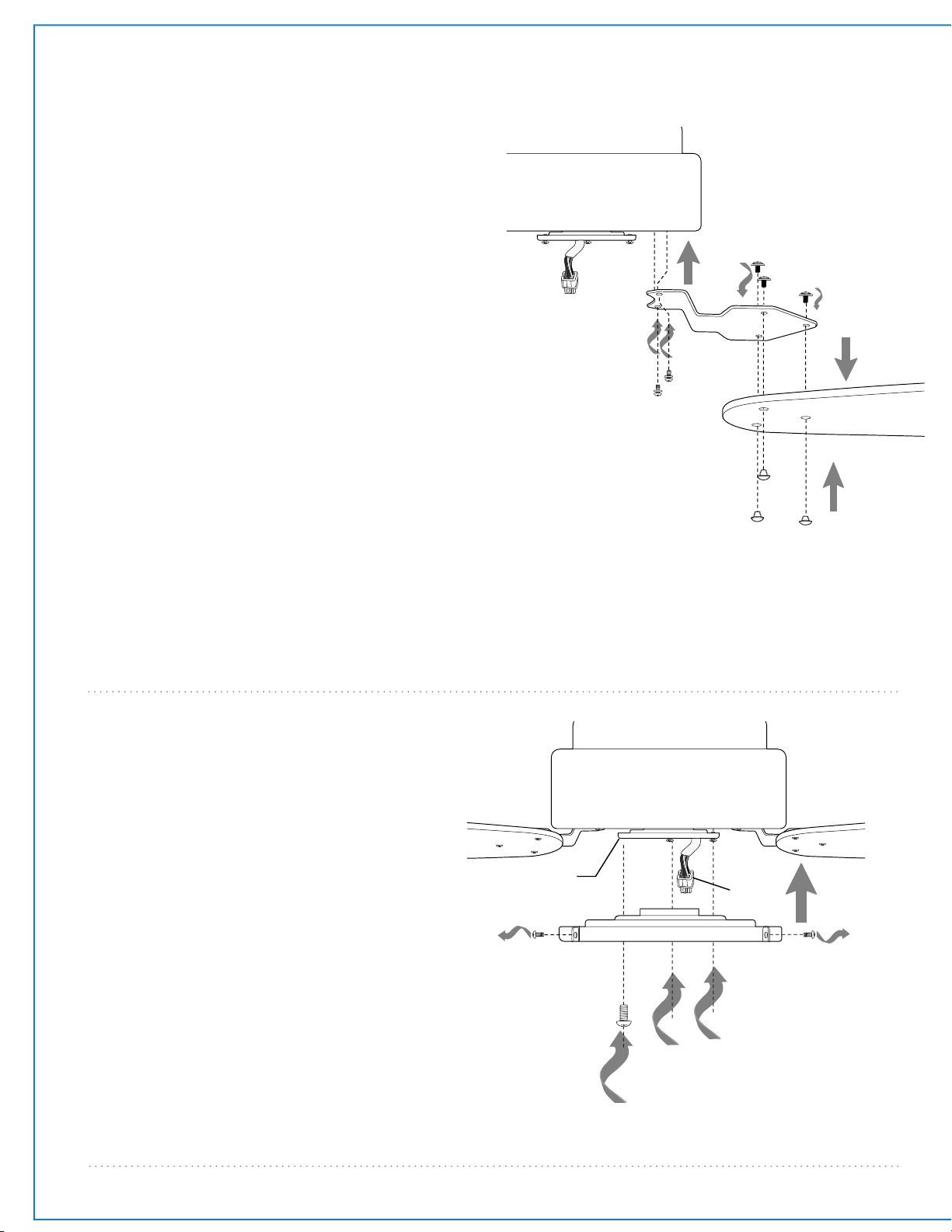

9. Blade Assembly.

blade arm

blade

motor housing

10. Light Kit Assembly.

Remove 3 screws from outer edge of

fitter plate (save screws for later use).

Remove 1 screw from motor plate on

underside of motor housing and partially

loosen the other 2 screws.

Align slotted holes in middle of fitter

plate with loosened screws in motor

plate, allowing male plug from motor

housing to come through center hole in

fitter plate. Twist fitter plate to lock.

Re-insert screw that was previously

removed and securely tighten all 3

screws with a Phillips screwdriver.

["Light Kit Assembly" continued on

next page.]

motor

housing

male

plug

fitter plate

motor plate

WARNING: To reduce the risk of serious bodily

injury, DO NOT use power tools to assemble the

blades. If overtightened, blades may crack and

break.

Locate 9 blade attachment screws and 9

decorative nuts in one of the hardware packs.

Place blade arm on TOPSIDE of blade, aligning

holes in blade arm with holes in blade as shown.

Insert 3 decorative nuts into holes in blade from

UNDERSIDE of blade (i.e., the side that will face the

floor), making sure to completely insert each

decorative nut so that the blade arm can be

attached correctly. Insert 3 blade attachment

screws from TOPSIDE of blade with fingers first

and then tighten screws securely with a Phillips

screwdriver. Repeat procedure for remaining

blades.

Remove blade arm screws and lock washers

from underside of motor. Align blade arm holes

with motor screw holes and attach blade arm

with lock washers and blade arm screws. Before

securing screws permanently, repeat this

procedure with remaining blade arms. Secure all

screws.

Note: Tighten blade arm screws twice a year.

decorative

nuts

blade attachment

screws

blade arm screws/

lock washers

Loading ...

Loading ...