Loading ...

Loading ...

Loading ...

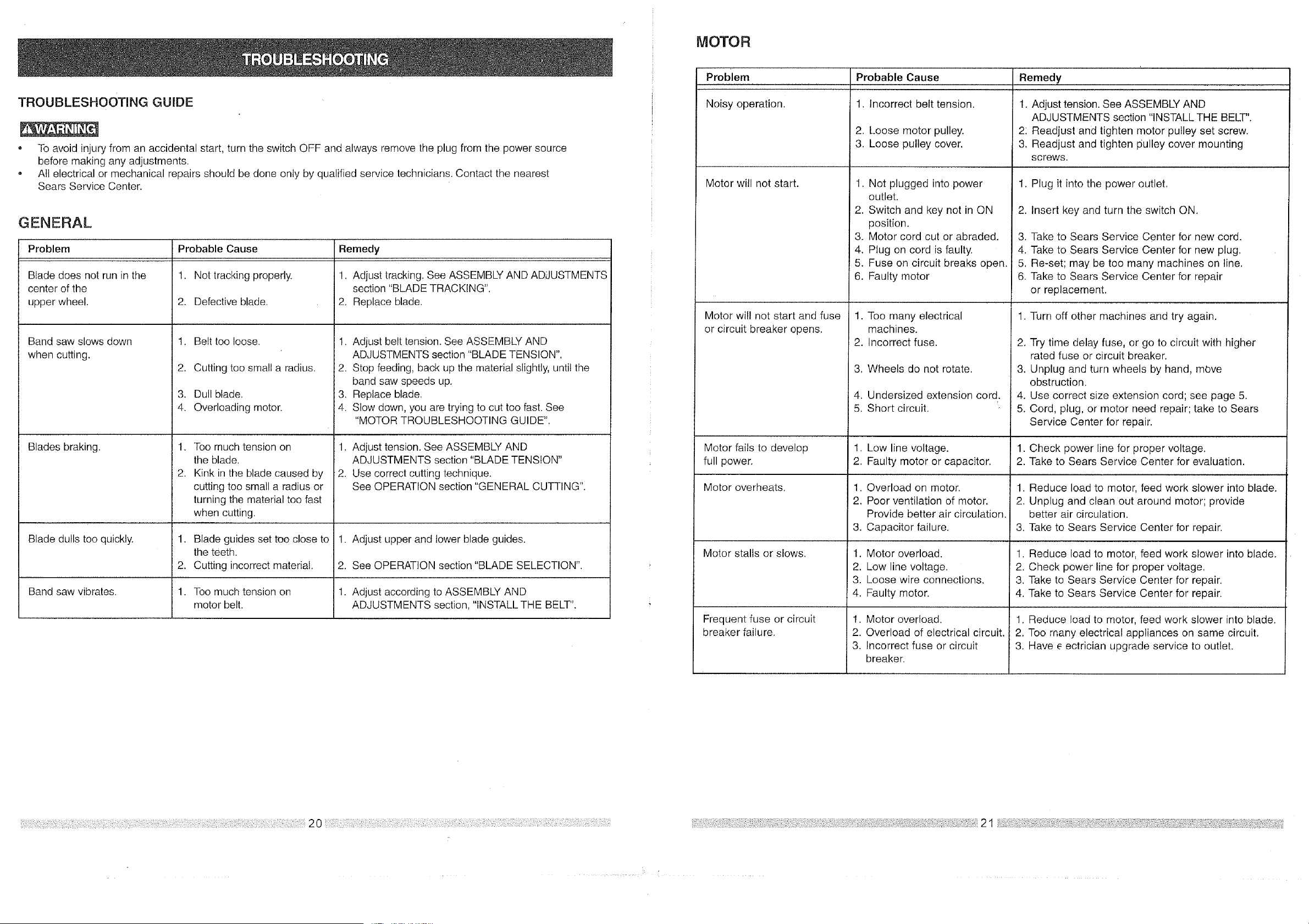

MOTOR

TROUBLESHOOTING GUIDE

, To avoid injury from an accidental start, turn the switch OFF and always remove the plug from the power source

before making any adjustments.

+ All electrical or mechanical repairs should be done only by qualified service technicians• Contact the nearest

Sears Service Center.

GENERAL

Problem

Blade does not run in the

center of the

upper wheel.

Band saw slows down

when cutting.

Blades braking.

Blade dulls too quickly.

Probable Cause

1. Not tracking properly.

2. Defective blade.

1. Belt too loose•

2. Cutting too small a radius.

3. Dull blade.

4. Overloading motor.

1. Too much tension on

the blade•

2. Kink inthe blade caused by

cutting too small a radius or

turning the material too fast

when cutting.

1. Blade guides set toe close to

the teeth.

2. Cutting incorrect material•

Band saw vibrates. 1. Too much tension on

motor belt.

Remedy

1. Adjust tracking. See ASSEMBLY AND ADJUSTMENTS

section "BLADE TRACKING".

2. Replace blade.

1. Adjust belt tension. See ASSEMBLY AND

ADJUSTMENTS section "BLADE TENSION".

2. Stop feeding, back up the material slightly, until the

band saw speeds up.

3. Replace blade.

4. Slow down, you are trying to cut too fast. See

"MOTOR TROUBLESHOOTING GUIDE".

1. Adjust tension. See ASSEMBLY AND

ADJUSTMENTS section "BLADE TENSION"

2. Use correct cutting technique.

See OPERATION section "GENERAL CUTTING".

1. Adjust upper and lower blade guides.

2. See OPERATION section "BLADE SELECTION".

1. Adjust according to ASSEMBLY AND

ADJUSTMENTS section, "INSTALL THE BELT".

Problem

Noisy operation.

Motor will not start.

Motor will not start and fuse

or circuit breaker opens.

Motor fails to develop

full power.

Motor overheats•

Motor stalls or slows•

Frequent fuse or circuit

breaker failure.

Probable Cause

1. Incorrect belt tension.

2. Loose motor pulley.

3. Loose pulley cover.

.

.

.

4.

5.

6.

.

2.

3.

4.

5.

1,

2.

.

2.

3.

1

2.

3.

4.

1

2.

3.

Not plugged into power

outlet•

Switch and key not in ON 2.

position.

Motor cord cut or abraded. 3.

Plug on cord is faulty. 4.

Fuse on circuit breaks open. 5.

Faulty motor 6.

Too many electrical 1.

machines.

Incorrect fuse. 2.

Wheels do not rotate• 3.

Undersized extension cord. 4.

Short circuit. 5.

Low line voltage.

Faulty motor or capacitor.

Overload on motor. 1.

Poor ventilation of motor. 2.

Provide better air circulation.

Capacitor failure. 3.

• Motor overload. 1.

Low line voltage. 2.

Loose wire connections• 3.

Faulty motor. 4.

• Motor overload.

Overload of electrical circuit.

Incorrect fuse or circuit

breaker.

Remedy

1. Adjust tension. See ASSEMBLY AND

ADJUSTMENTS section "INSTALL THE BELT".

2: Readjust and tighten motor pulley set screw.

3. Readjust and tighten pulley cover mounting

screws.

1. Plug it into the power outlet.

Insert key and turn the switch ON.

Take to Sears Service Center for new cord.

Take to Sears Service Center for new plug.

Re-set; may be too many machines on line.

Take to Sears Service Center for repair

or replacement•

Turn off other machines and try again.

Try time delay fuse, or go to circuit with higher

rated fuse or circuit breaker.

Unplug and turn wheels by hand, move

obstruction.

Use correct size extension cord; see page 5.

Cord, plug, or motor need repair; take to Sears

Service Center for repair.

1. Check power line for proper voltage.

2. Take to Sears Service Center for evaluation.

Reduce load to motor, feed work slower into blade•

Unplug and clean out around motor; provide

better air circulation.

Take to Sears Service Center for repair•

Reduce load to motor, feed work slower into blade.

Check power line for proper voltage.

Take to Sears Service Center for repair.

Take to Sears Service Center for repair.

1. Reduce load to motor, feed work slower into blade.

2. Too many electrical appliances on same circuit.

3. Have eectrician upgrade service to outlet.

21

Loading ...

Loading ...

Loading ...