Loading ...

158.120

158.12000

158.12020

158.121

1 58.12250

158.12260

1 58.220

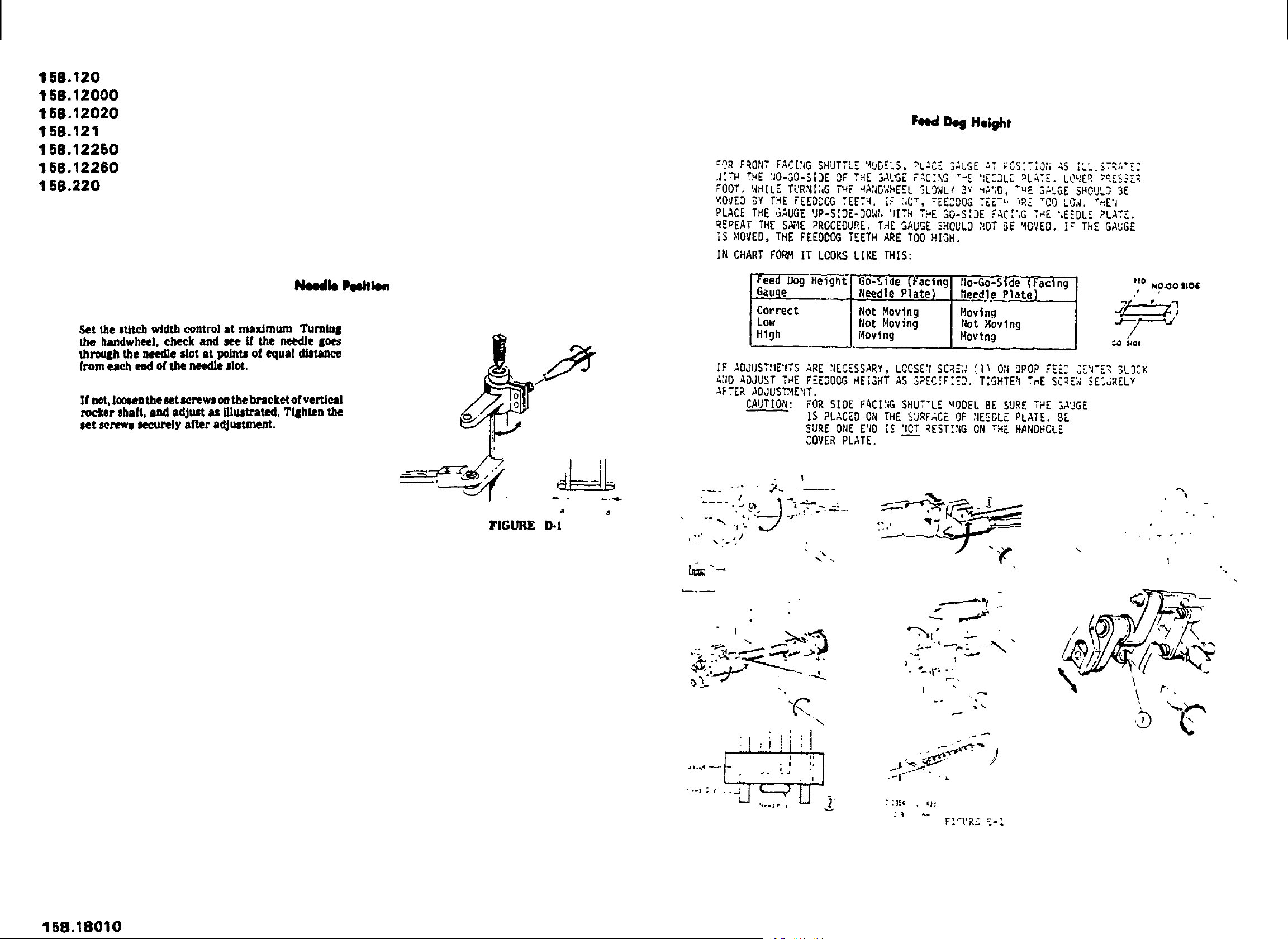

NeedlePmdtle.

Set thestitch width control at maximum Turnlni

the handwheel,cheek and see If the nero goes

throuEh the needle slot at points of equal diltanee

from each end of the needle slot.

If not, loosen the set screws on the bracket of vertical

rocker shaft, and adjust as illustrated. T_hten the

set screws securely after adjustment.

FIGURE D-I

Feed 0cO Height

:OR FRO_ITFA,_,I:_GSHUTTLE '_g&ELS,-_LzC_;_US[ _T ;OS:TIOI__,S;LL.STR'.'ZC

._ITHTHE _IO-GO-SI_EOF THE SALSE F':,C:_S"_E ':Z=SL__L_TE. LO'.IER_R[_.._ZR

FOOT. WHILE TL'RNI:,GT_F 4A:|G'._HEELSLOWL¢ 3v _';D, ÷uE SALGE GHOUL] SE

'4OVE3BY THE FEEDCOG TEETH. ;F :40T, :EE_DOG TF.F'T_._RE "00 LO._._HE'_

PLACE THE GAUGE UP-SIDE-DOW_J'rITHT._ESO-SIDE FACI',GT#[ ',EEDLEPLATE.

REPEAT THE SM'IEPROCEDURE. THE GAUGE SHOULD ;.'OTBE '_OVED. I_ THE GAUGE

IS ,_IOVED,THE FEEDDOG TEETH ARE TOO HIGH.

IN CHART FORM IT LOOKS LIKE THIS:

Feed Dog Height Go-Side (FacingI r|o-Go-Si_ (Facing l ,,oNo_ossos

Gauge Needle Plate} I Needle P_ate) i '"

COrrect Hot Moving I Moving _._-------_/

Low Hot Moving lHot Moving

High _ovlng J Moving

IF ADJUST)IE'ITSARE :IEOESSARY,LODGE';SCRE:(',ll0_IDROP ,€':'-.=-_'I'[_"_LD_Kr'

&:(DADJUST T#E FEEDDOG HEIGHT AS SPECIFIED. TIGHTE_ T_[ SCI[',.;S[;.JREL'_

AFTER ADJUS,_,<E'4T.

CAUTION: FOR SIDE FACI2;GSHUT'L[ _ODEL BE SURE T_E )AUGE

IS _LACED ON THE SJRFACE OF :|EEDLEPLATE. B_.

SURE ONE E'¢OIS 'lOTRESTING ON .'HEHANDHGLE

COVER PLATE.

I

\

. _,_;-

I

• _ • o ,

/

158.18010

Loading ...

Loading ...

Loading ...