Loading ...

Loading ...

Loading ...

EN

©2021 Hestan Commercial Corporation

17

INSTALLATION OF DISPENSING EQUIPMENT

(continued)

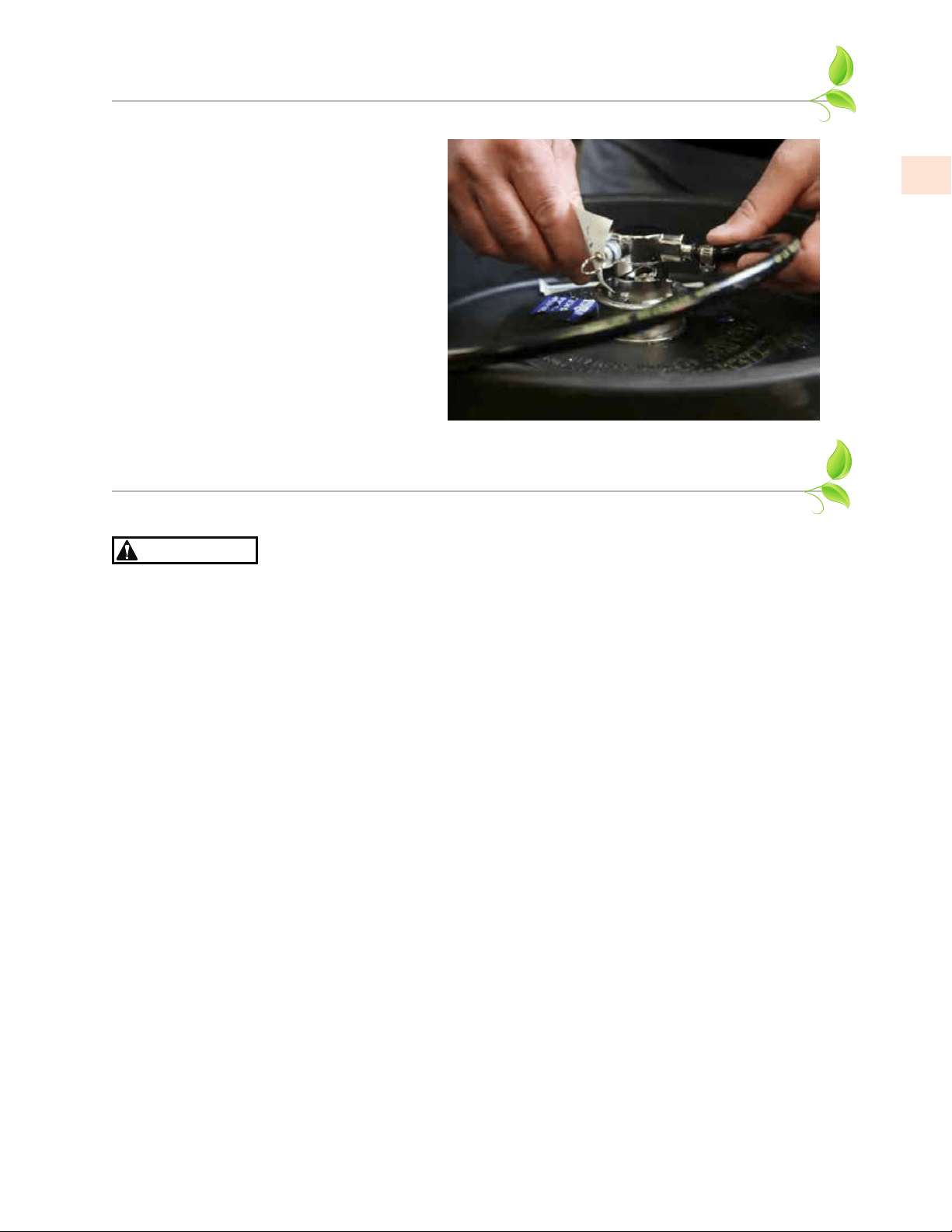

13. Before tapping a keg, make sure the

beer faucet is closed.

To tap a keg, insert the coupler into

the neck of the barrel. Turn the

coupler clockwise until it stops (about

an 1/8 turn), then push down on the

top of the coupler and again turn

clockwise until it stops. Your barrel is

now tapped.

Open the CO

2

valve on the regulator

as well as the valve on the manifold if

used.

CONNECTING THE REGULATOR TO THE CO

2

CYLINDER

HIGH-PRESSURE GASHIGH-PRESSURE GAS

DANGER

CO

2

cylinders contain high-pressure gas which can be hazardous if not handled properly. Make sure

you READ and UNDERSTAND the following procedures for CO

2

cylinders BEFORE installation.

• ALWAYS connect the CO

2

cylinder to a regulator. Failure to do so could result in an explosion

with possible death or injury when the cylinder valve is opened.

• NEVER connect the CO

2

cylinder directly to the product container (keg). Doing so will result in

an explosion causing possible death or injury.

• ALWAYS follow correct procedures when cylinders are changed.

• ALWAYS secure the cylinder in an upright position with a chain.

• NEVER drop or throw a CO

2

cylinder.

• ALWAYS keep a CO

2

cylinder away from heat. The rupture disc vents at 122°F [50°C] max.

Store extra cylinders in a cool place (preferably 70ºF [21°C]). Securely fasten with a chain in an

upright position when storing. NEVER place cylinders in direct sunlight or where temperature

could rise above 130ºF [54°C].

• ALWAYS ventilate & leave the area immediately if CO

2

gas leakage has occurred. NEVER enter

a closed area where leakage may have occurred.

• ALWAYS check the DOT test date on the cylinder neck before installation. If over five(5) years

old, do not use, return cylinder to gas supplier.

• NEVER connect a product container unless there are two(2) safeties in the pressure system:

(a) one at or on the CO

2

regulator.

(b) one at or on the product coupler or in the pressure gas line.

• CO

2

regulators are delicate instruments and should be checked constantly for creeping,

sluggishness, damaged gauges, or any unusual behavior. If any of these symptoms occur,

discontinue use immediately and return regulator to supplier or manufacturer.

• Allow only properly trained and experienced personnel to handle high-pressure gas.

• Do not apply oil to the regulator!

FAILURE TO CONNECT THE REGULATOR BY PROPERLY FOLLOWING THESE INSTRUCTIONS MAY

RESULT IN LEAKS, EXPLOSIONS, ASPHYXIATION AND CAUSE SERIOUS PERSONAL INJURY OR DEATH.

Loading ...

Loading ...

Loading ...