Loading ...

Loading ...

Loading ...

65BDL3550Q

51

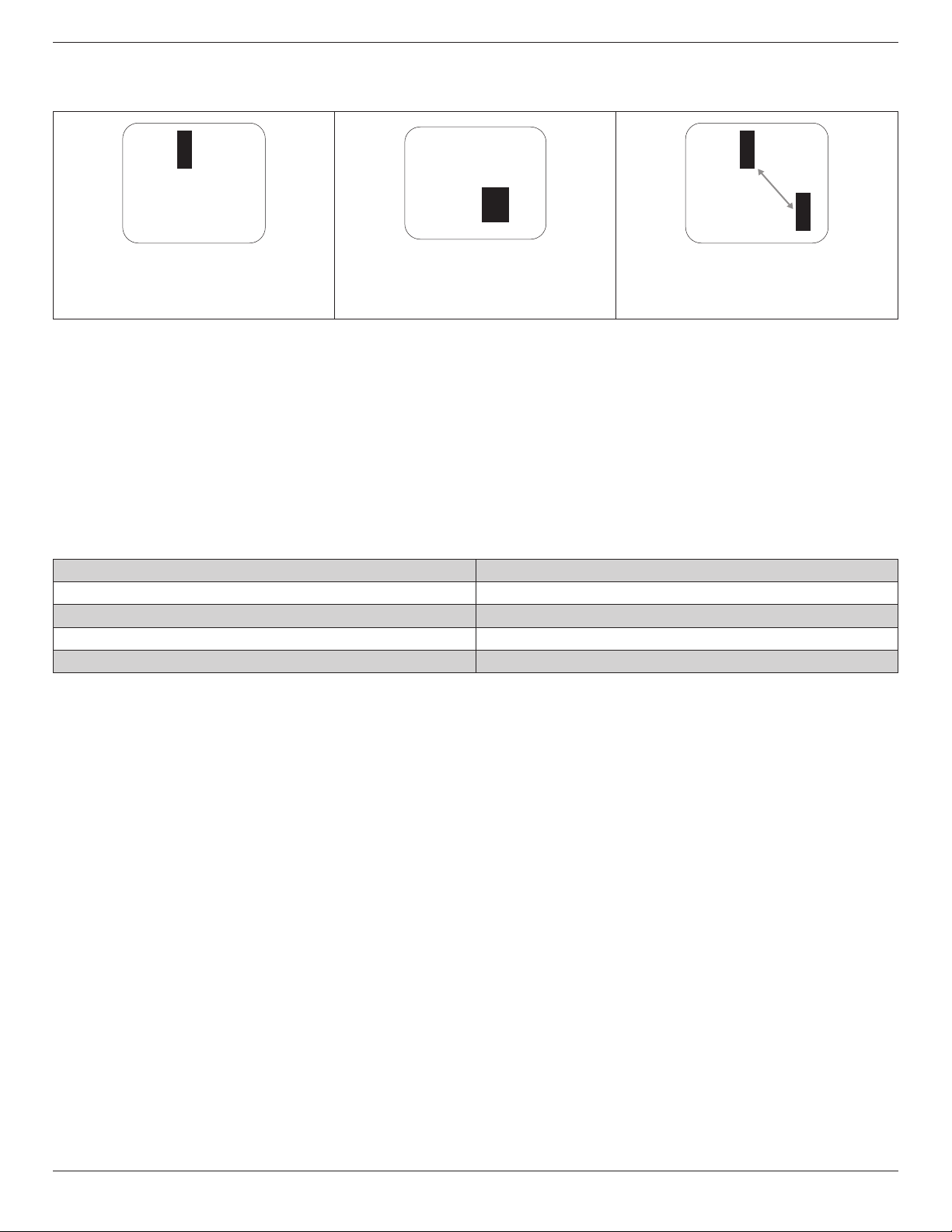

9.4. Dark Dot Defects

Black dot defects appear as pixels or sub-pixels that are always dark or “o”. These are the examples of black dot defects:

One dark dot Two adjacent dark dots = 1 pair of dark

dots

Two dark dots, specications denes

the minimum distance between dark

dots

9.5. Proximity of Pixel Defects

Because pixel and sub-pixels defects of the same type that are nearby one another may be more noticeable, Philips also

species tolerances for the proximity of pixel defects. In the table below you can nd specications about:

• Allowed amount of adjacent dark dots = (adjacent dark dots =1 pair of dark dots)

• Minimum distance between dark dots

• Total no. of all defective dots

9.6. Pixel Defect Tolerances

In order to qualify for repair due to pixel defects during the warranty period, a PDP / TFT panel in a Philips Plasma / LCD-

display must have pixel or sub-pixel defects exceeding the tolerances listed in the following table.

BRIGHT DOT EFFECT ACCEPTABLE LEVEL

1 lit sub pixel 2

BLACK DOT EFFECT ACCEPTABLE LEVEL

1 dark sub pixel 10

TOTAL DOT DEFECTS OF ALL TYPES 12

NOTE: * 1 or 2 adjacent sub pixel defects = 1 dot defect

9.7. MURA

Dark spots or patches may occasionally appear on some liquid crystal display (LCD) panels. This is known within the industry

as Mura, which is a Japanese term for “unevenness.” It is used to describe an irregular pattern or area in which uneven screen

uniformity appears under certain conditions. Mura is a result of the deterioration of the liquid crystal alignment layer and is most

commonly caused by long-term operation under high ambient temperatures. It is an industry- wide phenomenon and Mura is

not repairable. It is also not covered by our warranty terms.

Mura has been around since the introduction of LCD technology and with screens getting bigger and in operation 24/7, many

displays are running in low light conditions. This all adds to the possibility of Mura aecting displays.

HOW TO SPOT MURA

There are many symptoms of Mura and also multiple causes. Several of these are listed below:

• Impurities or foreign particles in the crystal matrix

• Uneven distribution of LCD matrix during manufacturing

• Non-uniform luminance distribution of the backlight

• Panel assembly induced stress

• Flaws within the LCD cells

• Thermal induced stress - high temperature operation over long periods of time

Loading ...

Loading ...

Loading ...