Loading ...

Loading ...

Loading ...

Check Transmission Gear Oil

Checkthetransmissiongear oil after every 30 hoursof operation

orwheneveryou noticeanyoil leak. Operatingthe tiller whenthe

transmissionis lowon oil can resultin severedamage.

ToCheckthe TransmissionGearOil Level:

1. Checkthegearoil levelwhenthetransmissionis cool.Gearoil

will expandin warm operatingtemperaturesand this expansion

will providean incorrectoil levelreading.

2. With thetiller on levelground,pullthe DepthRegulatorLeverall

the wayup

3. Removetheoil fill plug from thetransmissionhousingand look

insidethe oilfill hole to locatethemaindrive shaftsituatedbelow

the hole.SeeFigure25.

\

J

Figure25

4. Thegearoil levelis correctif the gear oil is approximatelyhalfway

upthe side of the maindriveshaft.

5. If thegearoil levelis low,add gearoil as describednext.Ifthe

gearoillevelis okay,securelyreplacethe oil fill plug.

6. If addingonlya fewouncesof gear oil, useAPI ratedGb4 or

Gb5 gearoil havinga viscosityof SAE 140,SAE85%140 or SAE

80W-90.ifrefillinganemptytransmission,useonly Gb4 gear oil

havinga viscosityof SAE 85W-140or SAE 140.

7. Whilecheckingfrequentlyto avoidoverfilling,slowlyaddgearoilinto

theoilfill holeuntilit reachesthehalfwaypointonthedriveshaft.

8. Securelyreplacetheoil fill plug.

Change Transmission Gear Oil

Thetransmissiongearoildoes not needto be changedunlessit has

beencontaminatedwithdirt, sandor metalparticles.See an autho-

rizedSearsServiceCenterto havethetransmissiongearoil changed

orto scheduleservice,simplycontactSearsat 1-800-4-MY-HOME®.

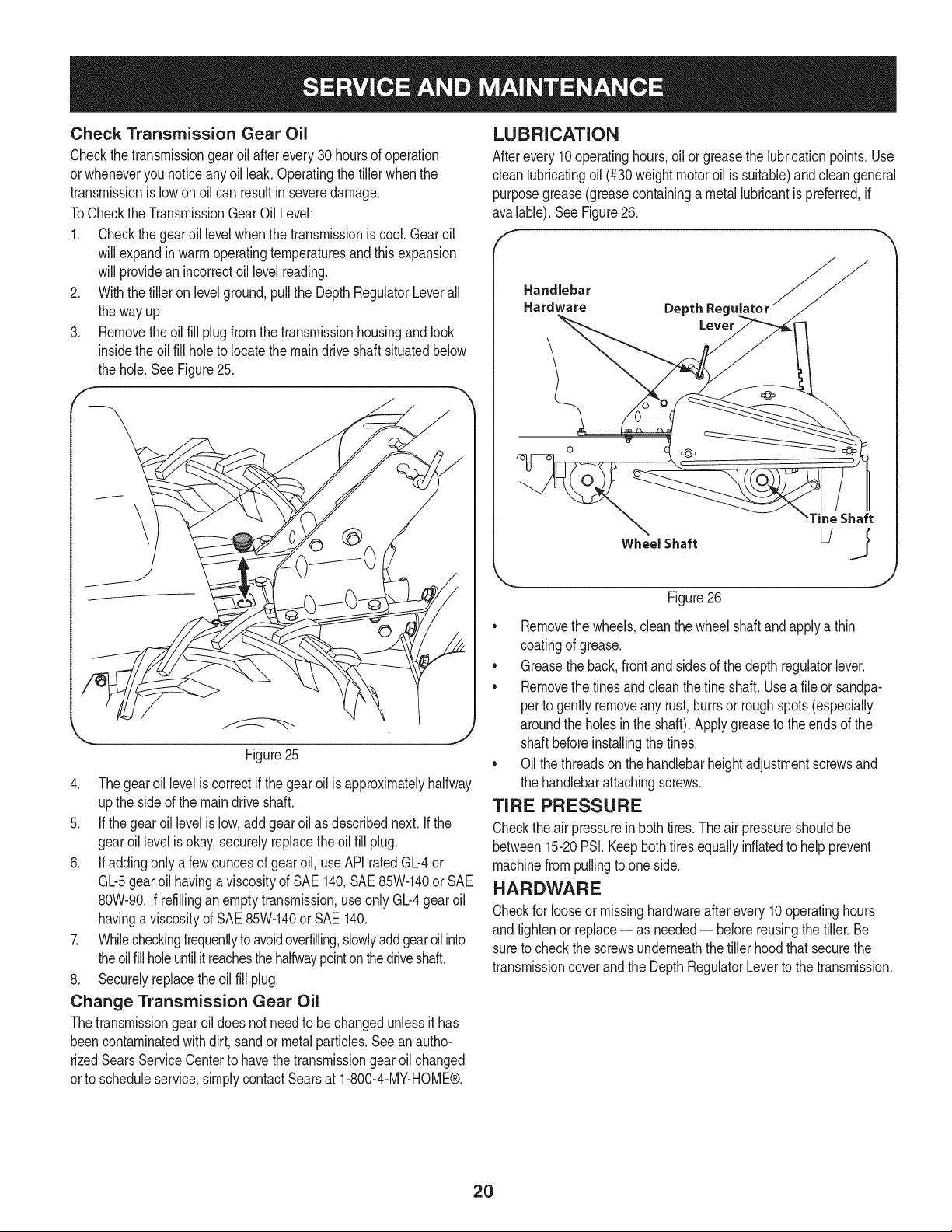

LUBRICATION

Afterevery10operatinghours,oil or greasethe lubricationpoints.Use

clean lubricatingoil (#30 weight motoroil is suitable)andcleangeneral

purposegrease(greasecontaininga metal lubricantis preferred,if

available).SeeFigure26.

Handlebar

Hardware Depth Reg_

Wheel Shaft

Tine Shaft

Figure26

• Removethe wheels,cleanthe wheelshaftand applya thin

coatingof grease.

• Greasethe back,frontandsidesof the depthregulatorlever.

• Removethe tines and cleanthefine shaft.Usea fileor sandpa-

perto gentlyremoveany rust,burrsor roughspots(especially

aroundthe holesin the shaft).Applygreaseto the endsof the

shaftbeforeinstallingthetines.

• Oil thethreadson the handlebarheightadjustmentscrewsand

the handlebarattachingscrews.

TIRE PRESSURE

Checkthe air pressurein both tires.Theair pressureshouldbe

between15-20PSI.Keepbothtiresequallyinflatedto helpprevent

machinefrompullingto oneside.

HARDWARE

Checkfor looseor missinghardwareafter every 10 operatinghours

andtightenor replace= as needed= beforereusingthe tiller.Be

sureto checkthe screwsunderneaththe tiller hoodthat securethe

transmissioncoverand the DepthRegulatorLeverto the transmission.

2O

Loading ...

Loading ...

Loading ...