Loading ...

Loading ...

Loading ...

9. BASIC IMPACT WRENCH OPERATIONS

9.3 VARIABLE TORQUE CONTROL

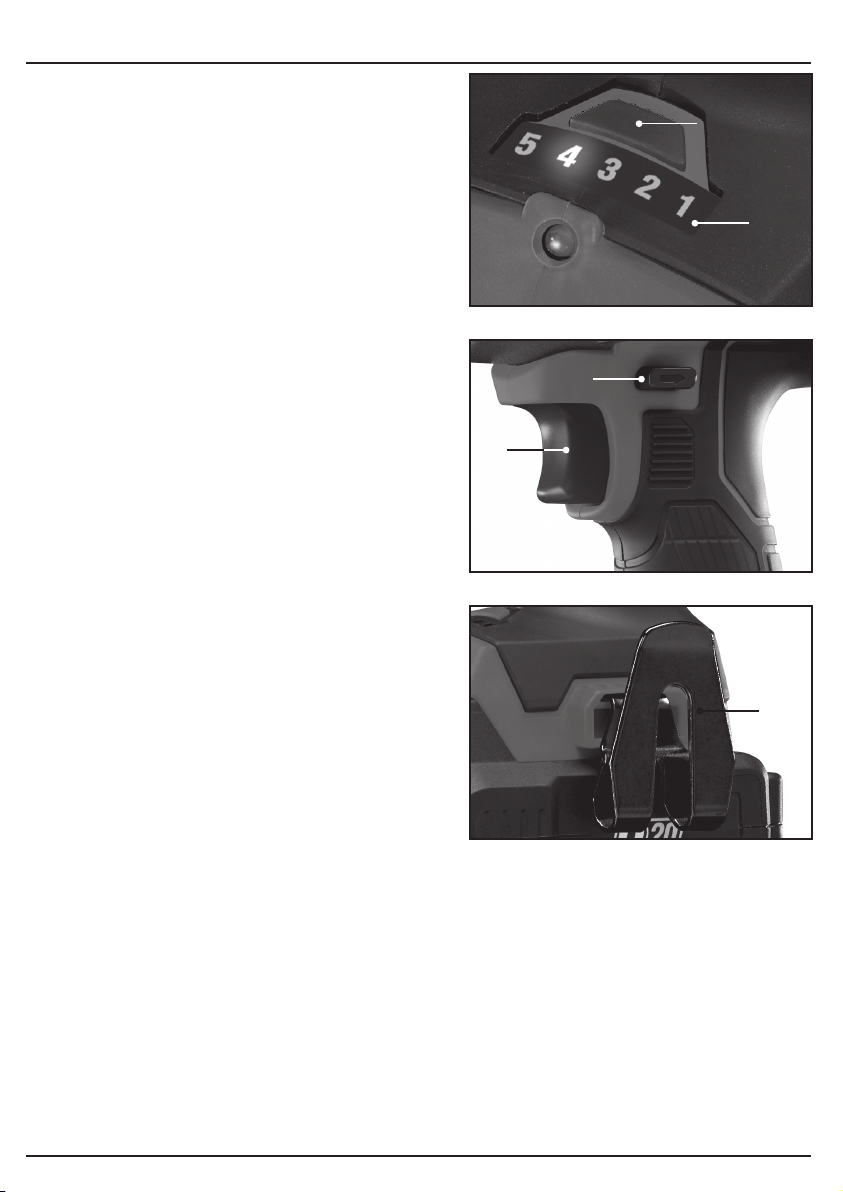

– FIG.6

The impact wrench has 5 pre-set torque settings,

ranging from high to low:

– Press the variable torque adjustment button

to select the required torque setting. Each

torque setting is indicated on the torque setting

display

.

– The display features 5 LED numbers that

illuminate incrementally from high torque to low

torque, each time the torque adjustment button

is pressed.

– High torque (circa 400Nm) – is No.5 on the left,

through to low torque, No.1 (circa 100Nm) – the

last on the right.

– The 3 lights between indicate the intermediate

torque settings.

9.4 VARIABLE SPEED TRIGGER

– FIG. 7

When the trigger

is depressed, the drive will

rotate (provided the direction switch

is set in

the forward or reverse position). The rotational

speed varies with the torque adjustment.

This trigger switch is electronic which enables the

user to vary the speed continuously.

– The speed varies according to how far the

trigger switch is depressed.

– The further it is depressed, the faster the drive

spindle will rotate.

– The lighter it is depressed, the slower it will

rotate.

Note:

It may be necessary to initially release fixings

with a hand tool prior to using the impact wrench.

Note:

Always tighten fixings to the correct torque

as indicated by the manufacturer using a calibrated

torque wrench. Failure to do so may result in the

fixing becoming damaged or insufficiently

tightened.

Note:

This product is equipped with an electric brake.

9.5 BELT CLIP – FIG. 8

The spring steel belt clip

is convenient for hanging the drill temporarily. The clip can be

installed on either side of the tool.

To install the clip:

– Locate the clip

in position and fasten with screw supplied, take care to not over-tighten and

strip the thread.

- 17 -

FIG.6

FIG.7

FIG.8

Loading ...

Loading ...

Loading ...