Loading ...

Loading ...

Loading ...

Section 4 - ADJUSTMENTS & REPAIR

WARNING A I

Before attempting any adjustments or repairs, STOP I

the engine, remove the spark plug wire from the l

spark plug and secure wire away from plug.

4.3 DRIVEN DISC SERVICE

If the mower does not propel itself properly, refer to

Figure 4.6. Check for the following problems:

DRIVEN DISC &

RUBBER RING

DRIVE

SPRING

ENGINE

DRIVE

BELT

DRIVE

DISC

O

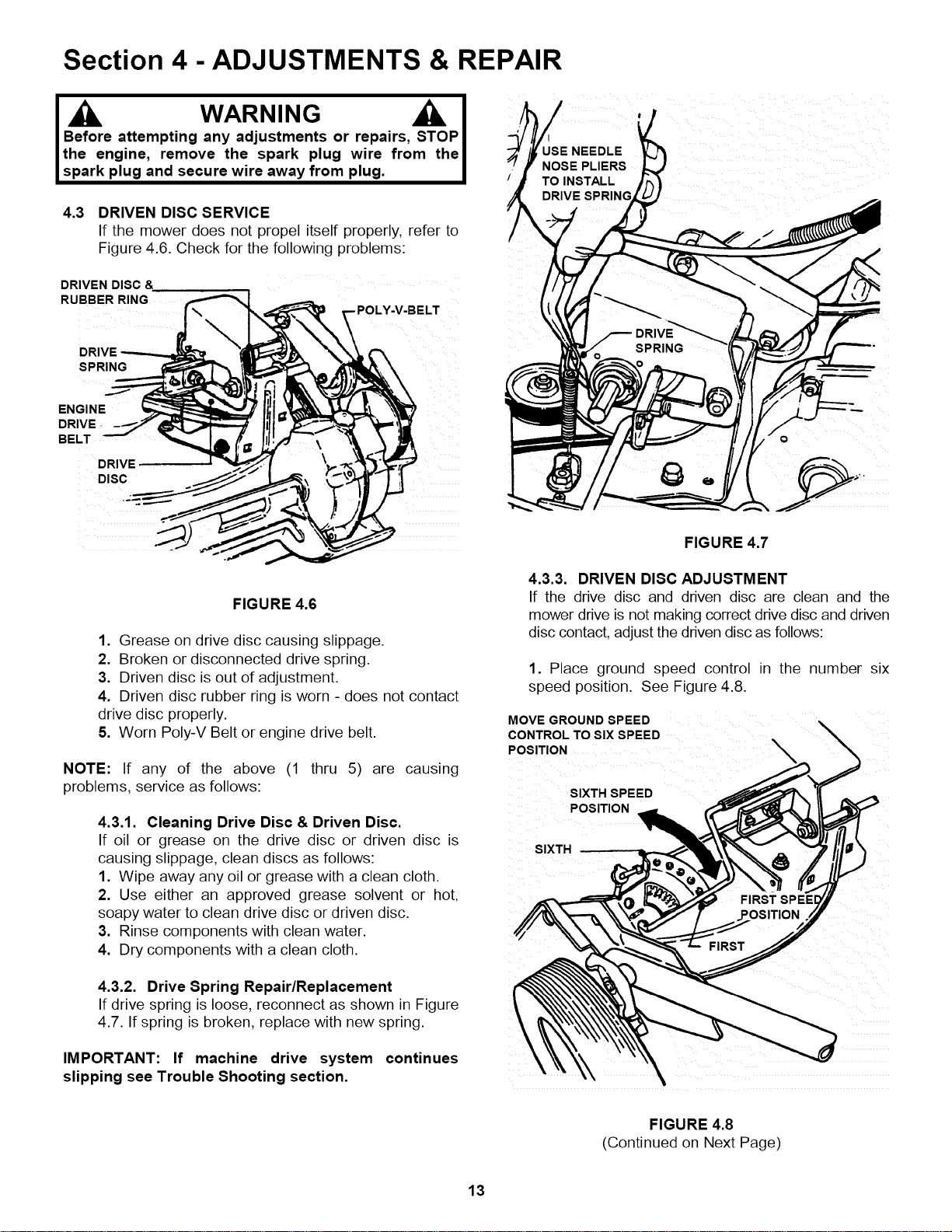

FIGURE 4.7

FIGURE 4.6

1. Grease on drive disc causing slippage.

2. Broken or disconnected drive spring.

3. Driven disc is out of adjustment.

4. Driven disc rubber ring is worn - does not contact

drive disc properly.

5. Worn Poly-V Belt or engine drive belt.

NOTE: If any of the above (1 thru 5) are causing

problems, service as follows:

4.3.1. Cleaning Drive Disc & Driven Disc.

If oil or grease on the drive disc or driven disc is

causing slippage, clean discs as follows:

1. Wipe away any oil or grease with a clean cloth.

2. Use either an approved grease solvent or hot,

soapy water to clean drive disc or driven disc.

3. Rinse components with clean water.

4. Dry components with a clean cloth.

4.3.2. Drive Spring Repair/Replacement

If drive spring is loose, reconnect as shown in Figure

4.7. If spring is broken, replace with new spring.

IMPORTANT: If machine drive system continues

slipping see Trouble Shooting section.

4.3.3. DRIVEN DISC ADJUSTMENT

If the drive disc and driven disc are clean and the

mower drive is not making correct drive disc and driven

disc contact, adjust the driven disc as follows:

1. Place ground speed control in the number six

speed position. See Figure 4.8.

MOVE GROUND SPEED

CONTROL TO SIX SPEED

POSITION

SIXTH

FIGURE 4.8

(Continued on Next Page)

13

Loading ...

Loading ...

Loading ...