Loading ...

Loading ...

Loading ...

8

SUPPLIER GRADE

BP Enerpar SE100

Conoco Pale Paraffi n 22

Mobile D.T.E. Oil Light

G & G Oil Circulating 22

Imperial Oil Voltesso-35

Shell Canada Transformer-10

Texaco Diala-Oil-AX

Woco Premium 100

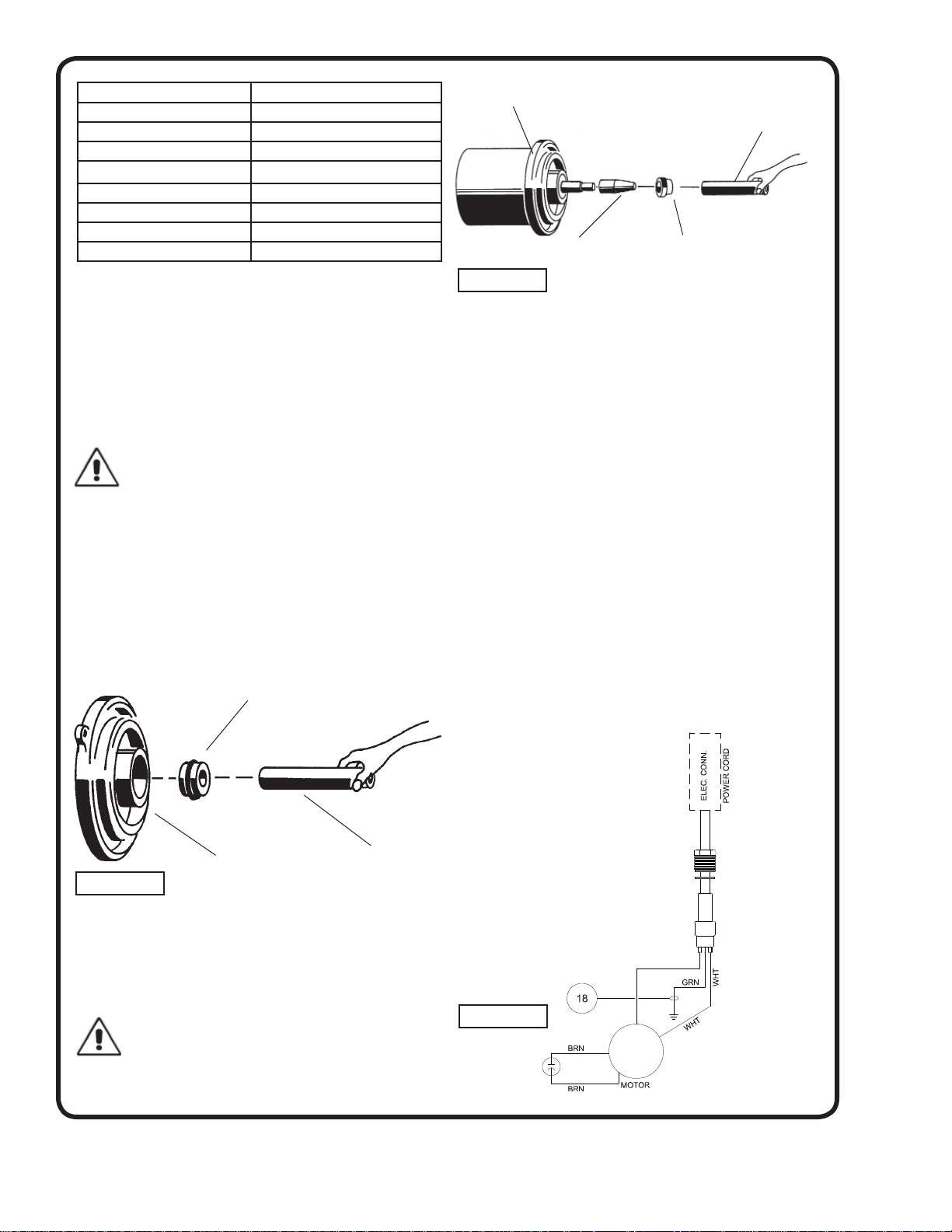

E-1 SHAFT SEAL SERVICE:

Disconnect power, remove screws and lockwashers, and

vertically lift motor assembly from body. Clean out body if

necessary. Clean and examine impeller for pitting or wear.

The impeller is threaded onto the shaft and to remove,

unscrew impeller, holding shaft with a large screwdriver.

CAUTION: - Handle seal parts with extreme care. DO

NOT scratch or mar lapped surfaces.

To expose shaft seal (1) disassemble volute and

impeller as outlined in above paragraph. Remove

rotating member (1b) from shaft (See Fig. 4). Examine all

seal parts and especially contact faces. Inspect seal for

signs of wear such as uneven wear pattern on stationary

members, chips and scratches on either seal face. DO

NOT interchange seal components, replace the entire

shaft seal (1). If replacing seal, remove stationary (1a) by

prying out with fl at screw driver.

Clean and oil seal cavities in lower motor housing. Lightly

oil (DO NOT use grease) outer surface of stationary

member (1a). Press stationary member (1a) fi rmly into

lower motor housing, using a seal pusher, nothing but the

seal pusher is to come in contact with seal face (See Fig. 5).

IMPORTANT ! - DO NOT hammer on the seal pusher- it

will damage the seal face.

Make sure the stationary member is in straight. Slide a

bullet (see parts list-seal tool kit) over motor shaft. Lightly

oil (DO NOT use grease) shaft, bullet and inner surface of

bellows on rotating member (1b) See Fig. 6. With lapped

surface of rotating member (1b) facing inward toward

stationary member (1a), slide rotating member (1b) over

bullet and onto shaft, using seal pusher, until lapped faces

of (1a) and (1b) are together (See Fig. 4).

It is extremely important to keep seal faces clean during

assembly. Dirt particles lodged between these faces will

cause the seal to leak. Place spring (1b) over shaft and in

place on rotating member (1c), making sure it is seated.

Slide retaining ring (1a) over shaft and let rest on spring

(1b).

Before installing impeller, inspect threads on shaft and

impeller to assure that they are clean. Apply a thread-

locking compound to shaft threads and screw impeller

onto shaft and tighten. Rotate impeller to check for

binding. Install motor housing assembly on pump body.

Apply thread locking compound to each cap screw, thread

into body with lockwashers, and torque to 11 ft. lbs. Check

for free rotation of impeller. Assemble impeller and volute

replace oil

SECTION: F REPLACEMENT PARTS

Seal Pusher

Lower Motor Housing

Stationary Member

(1d) Polished Face Out

Rotating Member

(1c)

Motor & Lower Motor

Housing

Bullet

Seal Pusher

FIGURE 5

FIGURE 6

SINGLE PHASE - 115 VOLTS

MANUAL & AUTOMATIC

FIGURE 7

Loading ...

Loading ...

Loading ...