Loading ...

Loading ...

Loading ...

5

SECTION B: GENERAL INFORMATION

B-1) To The Purchaser:

Congratulations! You are the owner of one of the fi nest

pumps on the market today. Barnes® Pumps are products

engineered and manufactured of high quality components.

Over one hundred years of pump building experience

along with a continuing quality assurance program com-

bine to produce a pump which will stand up to the toughest

applications.

Check local codes and requirements before installation.

Servicing should be performed by knowledgeable pump

service contractors or authorized service stations.

The pump is packaged ready for installation and no con-

nections or adjustments are necessary except for attaching

discharge piping and plugging in service cord.

B-2) Receiving:

Upon receiving the pump, it should be inspected for dam-

age or shortages. If damage has occurred, fi le a claim

immediately with the company that delivered the pump.

If the manual is removed from the crating, do not lose or

misplace.

B-3) Storage:

Short Term- Barnes Pumps are manufactured for effi cient

performance following long inoperative periods in storage.

For best results, pumps can be retained in storage, as

factory assembled, in a dry atmosphere with constant

temperatures for up to six (6) months.

Long Term- Any length of time exceeding six (6) months,

but not more than twenty four (24) months. The units

should be stored in a temperature controlled area, a roofed

over walled enclosure that provides protection from the

elements (rain, snow, wind blown dust, etc..), and whose

temperature can be maintained between +40 deg. F and

+120 deg. F. Pump should be stored in its original shipping

container and before initial start up, rotate impeller by hand

to assure seal and impeller rotate freely.

B-4) Service Centers:

For the location of the nearest Barnes Service Center,

check your Barnes representative or Crane Pumps

& Systems, Inc., Service Department in Piqua, Ohio,

telephone (937) 778-8947 or Crane Pumps & Systems

Canada, Inc., Bramton, Ontario, (905) 457-6223.

SECTION C: INSTALLATION

C-1) Location:

These pumping units are self-contained and are

recommended for use in a sump or basin. The sump or

basin shall be vented in accordance with local plumbing

codes. This pump is designed to pump effl uent or

wastewater, nonexplosive and noncorrosive liquids and

shall NOT be installed in locations classifi ed as hazardous

in accordance with the National Electrical Code (NEC),

ANSI/NFPA 70 or the Canadian Electrical Code. Never

install the pump in a trench, ditch, or hole with a dirt

bottom; the legs will sink into the dirt and the suction will

become plugged.

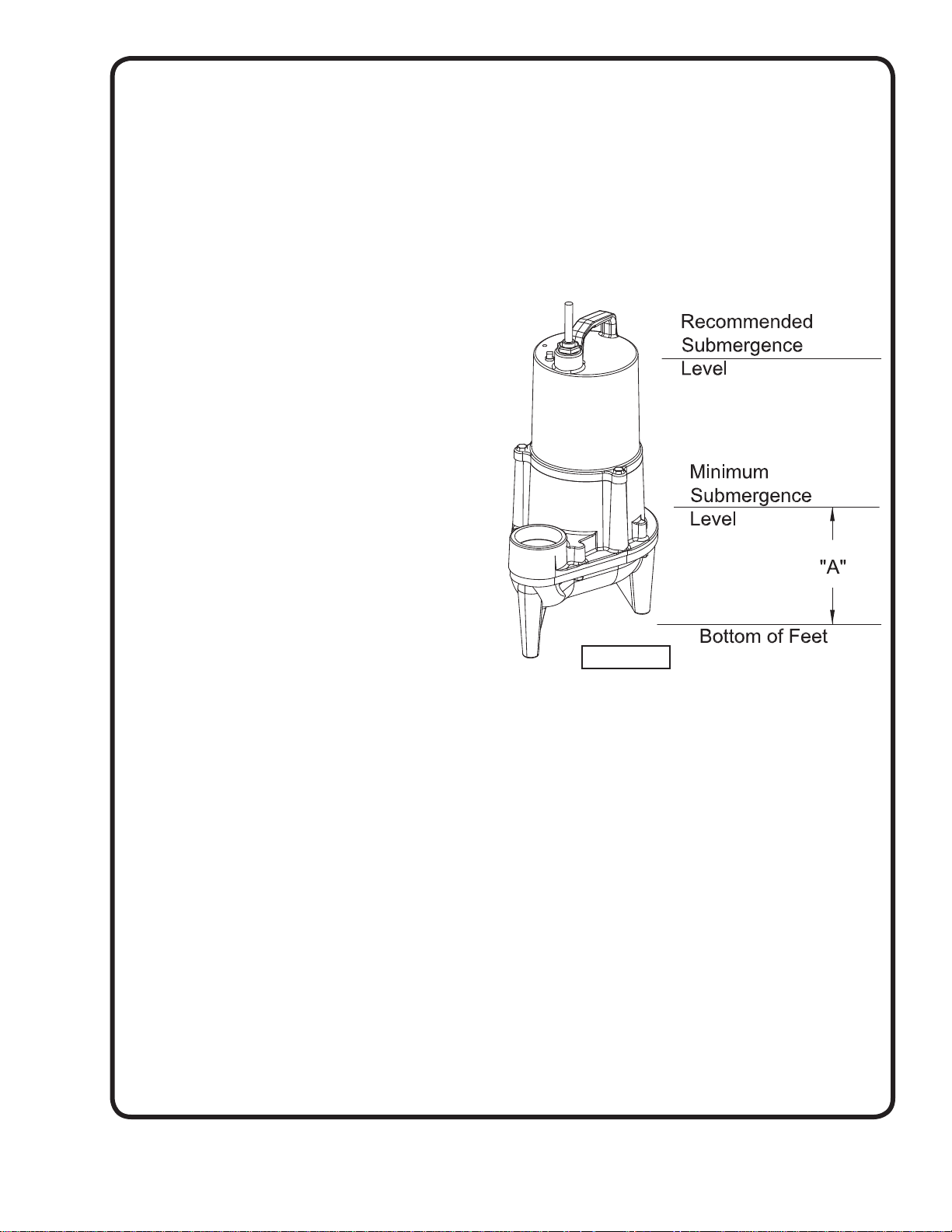

C-1.1) Submergence:

The pump should always be operated in the submerged

condition. The minimum sump liquid level should never be

less than A Dimension, A = 6.50 inches on SEV Series and

A=4.50 inches on EHV Series above the pump bottom.

The recommended level should not drop below the top of

the motor housing (see Fig. 1).

C-2) Discharge:

Discharge piping should be as short as possible. Both a

check valve and a shut-off valve are recommended for

each pump being used. The check valve is used to prevent

backfl ow into the sump. Excessive backfl ow can cause

fl ooding and/or damage to the pump. The shut-off valve

is used to stop system fl ow during pump or check valve

servicing.

C-3) Liquid Level Controls

Figure 2 shows a typical installation for any submersible

pump using a level control mounted to the discharge piping

with a piggy-back plug.

General Comments:

1) Never work in the sump with the power on.

2) Level controls are factory set for a pumping differential

of 9 inches. If that is the cycle desired, simply circle the

discharge pipe with the pipe mounting strap, feed the

end through the worm drive, and tighten with a

screwdriver. Be certain that the level control cannot

hang up or foul in its swing. Also, make certain the

pump impeller is still submerged when the level control

is in the “OFF” mode.

FIGURE 1

Loading ...

Loading ...

Loading ...