Loading ...

Loading ...

Loading ...

10

Maintenance of the Saw Chain and

Guide Bar

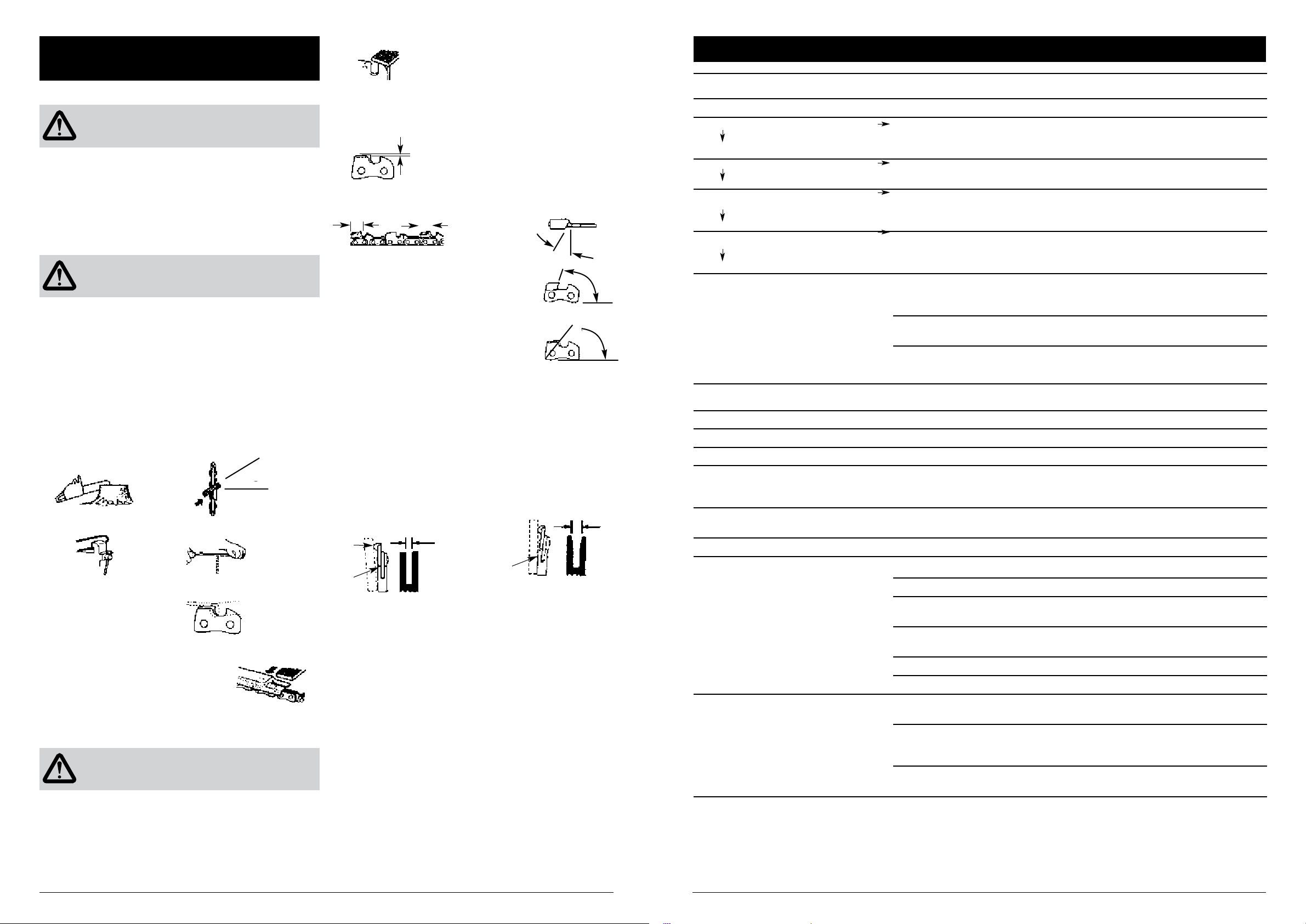

SAW CHAIN

WARNING!

It is very important for smooth and safe operation to

always keep the cutters sharp.

Your chain saw cutters need to be sharpened when.

• Sawdust becomes powder like.

• You need extra force to saw.

• The cut way does not go straight.

• Vibration increases.

• Fuel consumption increases.

Cutter setting standards.

WARNING!

Be sure to wear safety gloves when servicing.

Before ling:

• Make sure the saw chain is held securely.

• Make sure the engine is stopped and the spark plug dis-

connected.

• Use a round le of proper size for your chain.

Model MCS25 Chain: 91VG File size: 5/32” (4.0 mm)

Model MCS38 Chain: 91VG File size: 5/32” (4.0 mm)

Model MCS46 Chain: 21VB File size: 3/16 ” (4.76 mm)

Model MCS52 Chain: 21VB File size: 3/16 ” (4.76 mm)

Model YR4503 Chain: 21VB File size: 3/16 ” (4.76 mm)

30˚

90˚

20˚

Fix chain so it can not move.

• Place your le on the cutter and

push straight forward. Keep the le

positioned as illustrated.

• After every cutter has been set,

check the depth gauge and le it to

the proper level.

WARNING!

Be sure to round o the front edge to reduce the chance of

kickback or tiestrap breakage.

Appropriate gauge checker.

11

Make shoulder rounded.

Make sure every cutter has the same length and edge angles

as illustrated.

Depth gauge standard.

x

x

Cutter length

Filing angle

Side plate angle

Top plate angle

30˚

85˚

60˚

GUIDE BAR

• Flip the bar upside down occasionally to promote even

wear.

• The bar rail should always be a square. Check for wear of

the bar rail. Apply a ruler to the bar and the outside of a

cutter. If a gap is observed between them– the rail is nor-

mal.

Good guide bar

Rul-

er

Gap

Guide bar rail

Guide bar needs replacing

No gap. Chain should not move

sideways in the guide rail

Guide bar rail

worn

Trouble shooting

Engine does not start

What to Check Possible Cause Remedy

Does the engine crank?

YES

NO Faulty recoil starter.

Fluid in the crankcase.

Internal damage.

Return chainsaw to dealer

Good compression?

YES

NO Loose spark plug. Excess wear on cylinder,

piston, rings

Tighten and re-test. Return unit to

dealer

Does the tank contain fresh fuel

of the proper grade?

YES

NO Fuel/mixture incorrect, stale, contami-

nated.

Re-ll with fresh fuel (2-cycle

engine oil and gasoline, as speci-

ed.)

Is fuel visible and moving in the

return line when priming?

YES

NO Check for clogged fuel lter and/or vent. Clear as required. Re-start.

Check the spark plug If the plug is wet, excess fuel may be in the

cylinder

Crank the engine with plug

removed. replace the plug and

restart. (Refer to page 7)

The plug may be fouled or improperly

gapped

Clean and regap the plug to

0.65mm. Restart.

The plug may be damaged internally or of

the wrong size.

Replace the plug with the speci-

ed plug. Restart

Low power output

What to Check Possible Cause Remedy

Is the engine overheating? Operator is overworking the machine. Use lower throttle setting.

Carburettor mixture is too lean. Return chainsaw to dealer.

Improper fuel ratio. Re-ll with fresh fuel of the correct

mixture (2-cycle engine oil and

gasoline, in specied ratio Page 5.)

Fan cover, cylinder ns dirty or damaged. Clean, repair or replace as neces-

sary.

Carbon deposits on piston or in the muer. Decarbonize.

Engine is rough at all speeds. Clogged air cleaner element. Service the air cleaner.

May also have black smoke and/ Loose or damaged spark plug. Tighten or replace.

or unburned fuel at the exhaust. Air leakage or clogged fuel line. Repair or replace lter and/or fuel

line.

Water in the fuel. Drain the fuel replace the fuel with

a fresh mix.

Piston seizure. Return chainsaw to dealer.

Faulty carburettor and/or diaphragm. Return chainsaw to dealer.

Engine is knocking. Overheating condition. Idle engine until cool; nd reason

for overheating.

Improper fuel. Check fuel octane rating; check

for presence of alcohol in the fuel.

Refuel as necessary.

Carbon deposits in the combustion

chamber.

Decarbonize

Loading ...

Loading ...

Loading ...