Loading ...

Loading ...

Loading ...

6

engine.

Mix a regular 91 octane gasoline (leaded or unleaded, alcohol

free) and a quality proven motor oil for air cooled 2 cycle

engines.

Recommended mixing ratios:

Models MCS25, MCS38, MCS46, MCS52 and YR4503

Engine Condition Gasoline to Oil

Up to 20 hours use 25:1

All Models

After 20 hours use 25:1 or 40:1 (see below charts)

When using a mineral oil:

Mixing Ratio 25:1

Gasoline (litres) 1 2 3 4 5

2cycle oil (ml) 40 80 120 160 200

When using a semi-synthetic oil:

Mixing Ratio 40:1

Gasoline (litres) 1 2 3 4 5

2cycle oil (ml) 25 50 75 100 125

WARNING!

Keep open ames away from the area where fuel is handled

or stored. Mix and store fuel only in an approved gasoline

container.

IMPORTANT!

Most engine troubles are caused, directly or

indirectly, by the fuel used on the machine. Take special care

not to mix a motor oil for 4 cycle engines.

HOW TO MIX FUEL

WARNING!

Thorough mixing of the oil and fuel is critical to the

life and performance of the engine. Take extreme

care.

1. Measure out the quantities of gasoline and oil to be mixed.

2. Put some of the gasoline into a clean, fuel container.

3. Pour in all of the oil and agitate well.

4. Pour in the rest of gasoline and agitate again for at least

one minute. Some oils may take longer to mix depend-

ing on their ingredients. Thorough mixing is essential for

engine longevity.

FILLING THE FUEL TANK

1. Untwist and remove the fuel cap. Rest the fuel cap in a

dust free place.

2. Fill fuel tank to 80% of the full capacity.

MSC25 = 184mL, MSC38 = 264mL, MCS46, 52 & YR4503 =

440ml.

3. Fasten the fuel cap securely and wipe up any fuel spillage

from around the engine.

CHAIN OIL

All models

Use Masport Chain Bar Oil Part # 833043. This is specially

formulated to give best results. Alternatively you can use a

good quality motor oil, SAE 10W ~ 30 all year round or SAE

#30~#40 in Summer and SAE #20 in Winter.

Refer to specications pg13 for OIL TANK capacities.

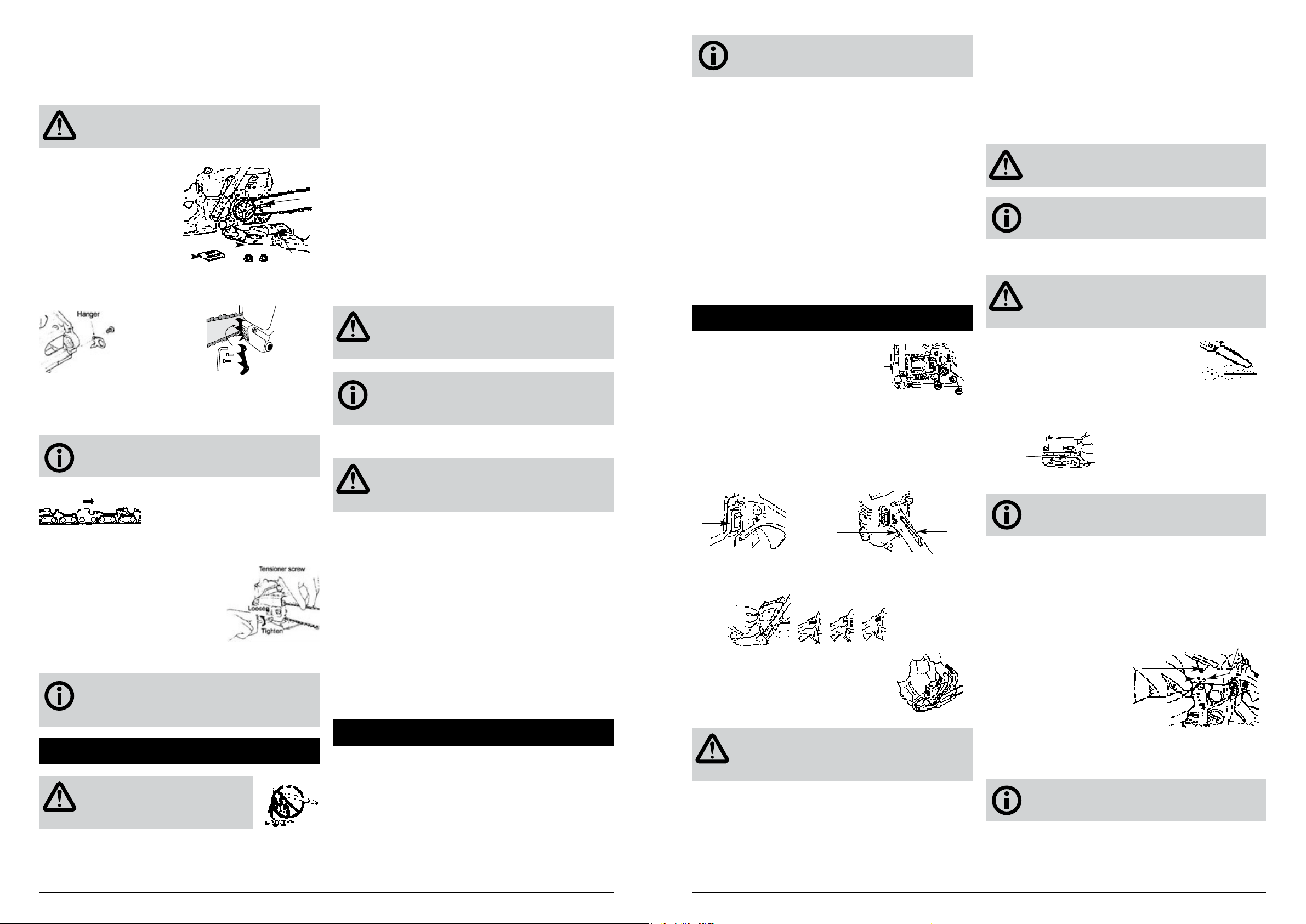

Open the box and assemble the guide bar and the saw chain

on the power unit as follows:

Note: For 45, 46 & 52 models assemble spike rst. Spike is

not needed for models S25 & 38.

WARNING!

The saw chain has very sharp edges. Use thick

protective gloves for safety.

1. Pull the front guard towards

the front handle to check

that the chain brake is not

engaged.

2. Loosen the nuts and

remove the chain cover.

3. Attach the spike to the

front, saw side of the

power unit.

4. Fix the hanger on the rear of

the power unit by screw - MSC25 only.

YR4503, MCS46 and

MCS52 only- tting

the Spike

5. Fit the chain over the sprocket and, while feeding the saw

chain around the guide bar, mount the guide bar to the

power unit. Adjust the position of chain tensioner nut on

the chain cover to the lower hole of guide bar.

IMPORTANT!

Pay attention to the correct direction of the saw chain.

6. Fit the chain cover to the power unit and fasten the nuts

until nger tight.

7. While holding up the tip of the bar, adjust the chain tension

by turning the tensioner screw until

the tie straps just touch the bottom

side of the guide bar.

8. Tighten the nuts securely with

the bar tip held up (12–15 Nm).

Then check the chain for smooth

rotation and proper tension while

moving it by hand. If necessary,

readjust.

IMPORTANT!

A new chain will stretch at the beginning of use. Check and

readjust the tension frequently as a loose chain can easily

derail or cause rapid chain wear and damage to the guide bar.

Fuel and Chain Oil Specications

WARNING!

Gasoline is very ammable. Avoid smoking

or bringing any naked ame or sparks near

the fuel.

Make sure to stop the engine and allow it to

cool before refuelling the unit. Select outdoor

bare ground for fuelling and move at

least 3m (10ft) away from the fuelling point before starting the

Hole

Tensone

nut

Chan cove

Tensioner screw

MCS38

MCS25,

45,46, 52

7

Push in the choke knob to closed position. Pull start

handle vigorously again until engine runs.

NOTE If the starter handle is pulled after the rst ring

sound is heard and the choke knob is in the start

position, too much fuel will enter into the engine resulting

in the engine failing to start.

3. Allow the engine to warm up with the choke lever pulled

out slightly.

WARNING!

Keep clear of the saw chain as it will start rotating

immediately upon starting of engine.

IMPORTANT!

When restarting immediately after stopping a hot

engine, leave the choke knob at the closed position

ADJUSTING THE OIL SUPPLY TO THE CHAIN

WARNING!

Make sure to set up the bar and the chain correctly

before adjusting the oil supply. If you don’t the rotating parts

may be exposed which is very dangerous.

After starting the engine. run the chain at

medium speed and see if excessive chain

oil is thrown o onto the ground.

Adjusting the Chain oil output.

The chain oil ow can be changed by inserting a screwdriver

in the hole on bottom of the clutch side. Adjust according to

your work conditions.

Chain Oil

Adjuster*

*This feature is not available on all models.

IMPORTANT!

The oil tank should become nearly empty by the time fuel is used

up. Be sure to rell the oil tank every time you refuel the unit.

STOPPING THE ENGINE

1. Release the throttle lever to allow the engine to idle for a

few minutes.

2. Set the switch to the “O” (STOP) position.

ADJUSTING THE CARBURETTOR

This is best done by an authorised Masport or

Morrison dealer

The carburettor on your

engine has been factory

adjusted, but may require

ne tuning due to changes in

operating conditions. Before

adjusting the carburettor

make sure that the provided

air and fuel lters are in good

condition and the fuel is properly mixed.

When adjusting take the following steps:

IMPORTANT!

Be sure to adjust the carburettor with the bar and

chain attached.

1. Stop engine and screw in both the ‘H’ and ‘L’ needles until

they stop. Never force them. Then set them back the initial

number of turns as shown below.

‘H’ Needle

‘L’ Needle

Idle adjuster

screw

IMPORTANT!

Do not use waste or recycled oil that can cause

damage to the oil pump.

TO GET MAXIMUM LIFE FROM YOUR ENGINE USE GOOD

QUALITY, WELL MIXED FUEL - AVOID...

1. Fuel with no oil (raw gasoline) that will very quickly cause

severe damage to the internal engine parts.

2. GASOHOL and E10. It can cause deterioration of rubber

and/or plastic parts and disruption of engine lubrication.

3. Mixing oils intended for use in four cycle engines with your

fuel. It can cause spark plug fouling, exhaust port blocking,

or piston ring sticking.

4. Mixed fuels which have been left unused for a period of

one month or more may clog the carburettor and result in

the engine failing to operate properly.

5. In the case of storing the chainsaw for a long period of

time, empty and clean the fuel tank. Turn the engine over to

empty the carburettor of the stale fuel.

6. When disposing of stale mixed fuel, take it to an authorised

disposal site.

Operating the Engine

STARTING THE ENGINE

Fill fuel and chain oil tanks respectively

and tighten the caps securely.

For models MCS25 & 38

1. Continuously push the priming

bulb until fuel comes into the bulb

(MCS25/38).

2. Put the switch to ‘I’ or up position.

3. Hold the throttle lever together with the throttle interlock

and push in the side throttle lock button. Release the

throttle lever to hold it at the starting position.

Throttle

interlock

Throttle

lever

Switch

4. Pull out the choke knob to the start position.

Closed

Choke

Knob

Start

5. While holding the saw unit securely

on the ground, pull the starter rope

vigorously.

WARNING!

Do not start the engine while dangling the chainsaw from

one hand. The saw chain may touch your body and cause

wounds that can be fatal.

6. If engine has started then stopped. Push the choke knob

in a little and pull the starter again to restart the engine

7. Allow the engine to warm up with the throttle lever pulled

out slightly.

For models MCS46, MCS52 and YR4503

1. For cold start, pull choke start lever.

2. Pull the starter cord until the rst ring sound is heard.

Fuel

Chain

Oil

Loading ...

Loading ...

Loading ...