Loading ...

Loading ...

Loading ...

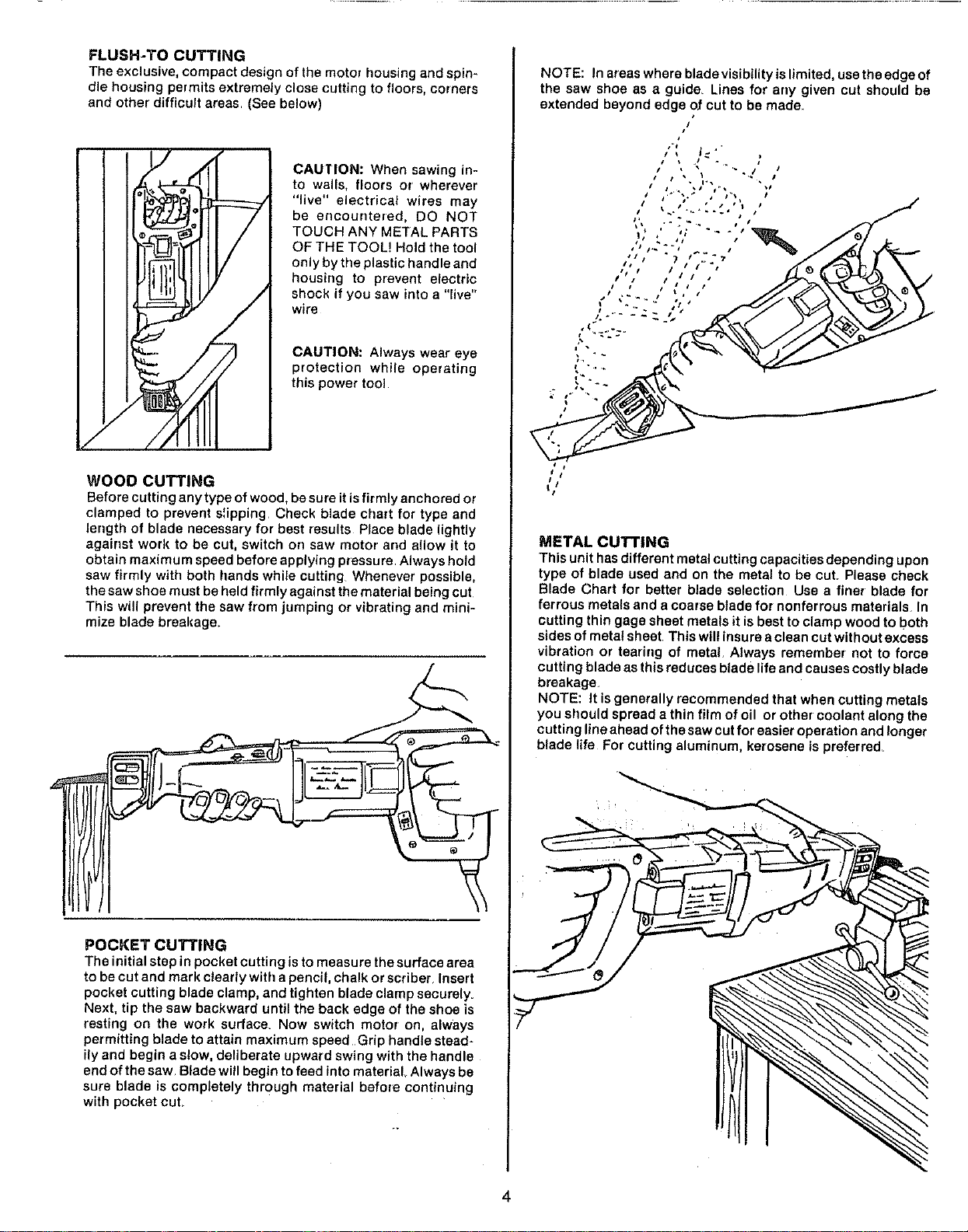

FLUSH-TO CUTTING

The exclusive, compact design of the motor housing and spin_

die housing permits extremely close cutting to floors, corners

and other difficult areas (See below)

Ii I°

CAUTION: When sawing in-

to walls, floors or wherever

"live" electrical wires may

be encountered, DO NOT

TOUCH ANY METAL PARTS

OF THE TOOL! Hold the tool

only by the plastic handle and

housing to prevent electric

shock if you saw into a "live"

wire

CAUTION: Always wear eye

protection while operating

this power tool

WOOD CUTTING

Before cutting any type of wood, be sure it is firmly anchored or

clamped to prevent s{ipping Check blade chart for type and

length of blade necessary for best results Place blade lightly

against work to be cut, switch on saw motor and allow it to

obtain maximum speed before applying pressure Always hold

saw firmly with both hands while cutting Whenever possible,

the saw shoe must be held firmly against the material being cut

This will prevent the saw from jumping or vibrating and mini-

mize blade breakage.

1

POCKET CUTTING

The initial step in pocket cutting isto measure the surface area

to be cut and mark clearly with a pencil, chalk or scriber. Insert

pocket cutting blade clamp, and tighten blade clamp securely.

Next, tip the saw backward until the back edge of the shoe is

resting on the work surface_ Now switch motor on, always

permitting blade to attain maximum speed Grip handle stead-

ily and begin a slow, deliberate upward swing with the handle

end of the saw Blade will begin to feed into materiel Always be

sure blade is completely through material before continuing

with pocket cuL

NOTE: In areas where blade visibility is limited, use the edge of

the saw shoe as a guide. Lines for any given cut should be

extended beyond edge o.fcut to be made

METAL CUTTING

This unit hasdifferent metal cutting capacities depending upon

type of blade used and on the metal to be cut. Please check

Blade Chart for better blade selection Usa a finer blade for

ferrous metals and a coarse blade for nonferrous materlals_ In

cutting thin gage sheet metals it isbest to clamp wood to both

sides of metal sheet This wilt insure a clean cut without excess

vibration or tearing of metal. Always remember not to force

cutting blade as this reduces blade life and causes costly blade

breakage_

NOTE: It is generally recommended that when cutting metals

you should spread a thin film of oil or other coolant along the

cutting line ahead of the saw cut for easier operation and longer

blade life For cutting aluminum, kerosene is preferred=

Loading ...

Loading ...

Loading ...