Loading ...

Loading ...

TROUBLE SHOOTING

CAUTION! Always disconnect the pump from the

electrical power source before handling. If the system

fails to operate properly, carefully read instructions and

perform maintenance recommendations.

If operating problems persist, the following chart may

be of assistance in identifying and correcting them:

MATCH “CAUSE” NUMBER WITH

CORRELATING “CORRECTION” NUMBER.

NOTE: Not all problems and corrections will apply to

each pump model.

PROBLEM CAUSE CORRECTION

Pump will not

run

1. Poor electrical

connection, blown fuse,

tripped breaker or other

interruption of power,

improper power supply.

2. Switch will not activate

pump or is defective.

3. Insuffi cient liquid level.

1. Check

all electrical

connections for

security. Check

for blown fuses,

tripped circuit

breakers or tripped

GFCI outlets.

2. Reposition

pump or clean

pump/basin

as required to

provide adequate

clearance for fl oat.

3. Make sure liquid

level is at least

equal to suggested

turn-on point.

4. Recheck all

sizing calculations

to determine proper

pump size.

5. Check discharge

line for restrictions,

including ice if line

passes through or

into cold areas.

6. Remove and

examine check

valve for proper

installation and

freedom of

operation.

7. Open valve.

8. Check impeller

for freedom of

operation, security

and condition.

Clean impeller

and inlet of any

obstruction.

9. Repair fi xtures

as required to

eliminate leakage.

10. Check pump

temperature limits

& fl uid temperature.

11. Replace portion

of discharge

pipe with fl exible

connector.

12. Check for leaks

around basin inlet

and outlets.

Pump will not

turn off

2. Switch will not activate

pump or is defective.

4. Excessive infl ow or

pump not properly sized

for application.

Pump hums but

does not run

1. Incorrect voltage

8. Impeller jammed or

loose on shaft, worn or

damaged, inlet plugged.

Pump delivers

insuffi cient

capacity

1. Incorrect voltage.

4. Excessive infl ow or

pump not properly sized

for application.

5. Discharge restricted.

6. Check valve stuck

closed or installed

backwards.

7. Shut-off valve closed.

8. Impeller jammed or

loose on shaft, worn or

damaged, inlet plugged.

Pump cycles

too frequently or

runs periodically

when fi xtures

are not in use

6. Check valve stuck

closed or installed

backwards.

9. Fixtures are leaking.

12. Ground water entering

basin.

Pump shuts off

and turns on

independent of

switch, (trips

thermal overload

protector).

CAUTION!

Pump may start

unexpectedly.

Disconnect

power supply.

1. Incorrect voltage.

4. Excessive infl ow or

pump not properly sized

for application.

8. Impeller jammed,

loose on shaft, worn or

damaged, inlet plugged.

10. Excessive water

temperature.

Pump operates

noisily or

vibrates

excessively

5. Discharge restricted.

8. Impeller broken.

11. Piping attachments to

building structure too rigid

or too loose.

LIMITATIONS: This series pumps are suitable to pump water with particles less than

.75”. The uid’s temperature limit is 40 centigrade (104°F) be careful not to pump hot

water, otherwise it will damage the pump. The pump cannot be used for sea water and

in ammable, corrosive, explosive or dangerous liquids.

Keep the pump equipment out of reach of children! Warns that the failure to follow the

directions given could cause serious risk to individuals or objects.

This sign warns the operator that the failure to follow any instruction may

damage the pump and/or the system.

This pump is designed for residential clean water jobs and can be used for

gasoline but cannot be used as a continuous duty fountain pump.

ELECTRICAL WIRE CONNECTION: Verify that the voltage and frequency of the electrode

pump shown on the nameplate correspond to those available on the mains. The installer

must make sure that the electric system is grounded in accordance with the law in force.

The plug and connections should be protected from water splashes. Before using the

pump, always inspect it visually (especially power cable and plug). Do not use the pump

if it is damaged. If the pump is damaged, have it inspected.

Make sure that electric connections are protected from inundation. Protect the plug

and the power cable from heats oil or the power cable must be replaced by quali ed

personnel only. The plug of the power cable has a double grounding contact, so that

grounding can be performed by simply inserting the plug.

OVERLOAD PROTECTION: This series pumps have built in thermal protection switch. The

pump stops if an overload condition occurs. The motor restarts automatically after it has

cooled down when the built in thermal protector resets.

ELECTRICAL PRECAUTIONS: Before servicing a pump, always shut o the main power

breaker and then unplug the pump. Make sure you are not standing in water and are

wearing insulated protective sole shoes, under ooded conditions. Contact your local

electric company or quali ed license electrician for removal.

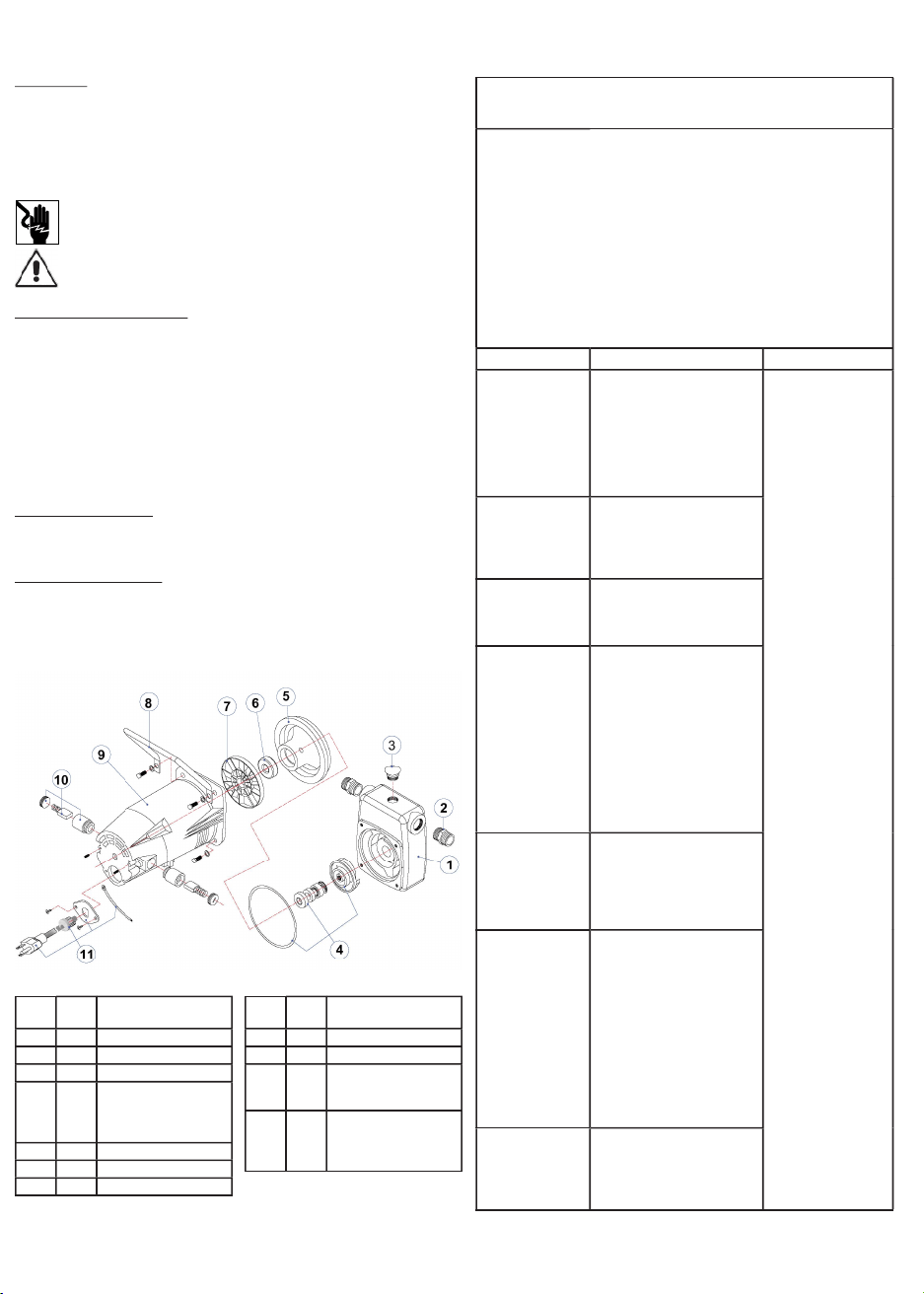

Item

No.

Qty. Description

1 1 Pump Body

2 2 Hose Fittings

3 1 Fill Plug

4 1 Overhaul Kit:

- Impeller

- Shaft Seal

- O-Ring

5 1 Seal Plate

6 1 Bearing

7 1 Fan

Item

No.

Qty. Description

8 1 Handle

9 1 Motor Assemble

10 1 Brush Kit:

- Brushed with springs

- Retainer Caps

11 1 Power Cord Set:

- Cable

- Cable Plate

- Ground Wire

Please Read This Before Installing Or Operating

Pump. This information is provided for SAFETY and

to PREVENT EQUIPMENT PROBLEMS. To help

recognize this information, observe the following

symbols:

IMPORTANT! Warns about hazards that can

result in personal injury or Indicates factors

concerned with assembly, installation,

operation, or maintenance which could result

in damage to the machine or equipment if

ignored.

CAUTION! Warns about hazards that can or will

cause minor personal injury or property damage if

ignored. Used with symbols below.

WARNING! Warns about hazards that can or will

cause serious personal injury, death, or major property

damage if ignored. Used with symbols below.

Only qualifi ed personnel should install, operate and

repair pump. Any wiring of pumps should be performed

by a qualifi ed electrician.

WARNING ! To reduce risk of electrical

shock, pumps and control panels must

be properly grounded in accordance with

the National Electric Code (NEC) or the

Canadian Electrical Code (CEC) and all

applicable state, province, local codes

and ordinances. Improper grounding voids

warranty.

WARNING! To reduce risk of electrical

shock, always disconnect the pump from the

power source before handling or servicing.

Lock out power and tag.

WARNING! Operation against

a closed discharge valve will

cause premature bearing and

seal failure on any pump, and

on end suction and self priming pump the heat build

may cause the generation of steam with resulting

dangerous pressures. It is recommended that a high

case temperature switch or pressure relief valve be

installed on the pump body.

CAUTION ! Never operate a pump with a

plug-in type power cord without a ground

fault circuit interrupter.

CAUTION ! Pumps build up heat

and pressure during operation-

allow time for pumps to cool before

handling or servicing.

WARNING ! Do not pump hazardous

materials (fl ammable, caustic, etc.) unless

the pump is specifi cally designed and

designated to handle them.

CAUTION ! Do not block or restrict discharge

hose, as discharge hose may whip under

pressure.

WARNING ! Do not wear loose clothing that

may become entangled in moving parts.

WARNING ! Keep clear of suction and

discharge openings. DO NOT insert fi ngers

in pump with power connected.

Always wear eye protection when working

on pumps.

Make sure lifting handles are securely

fastened each time before lifting. DO NOT

operate pump without safety devices in

place. Always replace safety devices that

have been removed during service or repair.

Secure the pump in its operating position so

it can not tip over, fall or slide.

DO NOT exceed manufacturers

recommendation for maximum performance,

as this could cause the motor to overheat.

DO NOT remove cord and strain relief.

DO NOT connect conduit to pump.

WARNING ! Cable should be protected at

all times to avoid punctures, cut, bruises

and abrasions. Inspect frequently. Never

handle connected power cords with wet

hands.

WARNING ! To reduce risk of electrical

shock, all wiring and junction connections

should be made per the NEC or CEC and

applicable state or province and local

codes. Requirements may vary depending

on usage and location.

WARNING! Submersible Pumps are not

approved for use in swimming pools,

recreational water installations decorative

fountains or any installation where human

contact with the pumped fl uid is common.

WARNING! Products returned must be

cleaned, sanitized, or decontaminated

as necessary prior to shipment, to insure

that employees will not be exposed to

health hazards in handling said material.

All Applicable Laws And Regulations Shall

Apply.

Bronze/brass and bronze/brass fi tted

pumps may contain lead levels higher than

considered safe for potable water systems.

Lead is known to cause cancer and birth

defects or other reproductive harm. Various

government agencies have determined that

leaded copper alloys should not be used in

potable water applications. For non-leaded

copper alloy materials of construction,

please contact factory.

Crane Pumps & Systems, Inc. is not

responsible for losses, injury, or death

resulting from a failure to observe these

safety precautions, misuse or abuse of

pumps or equipment.

SAFETY FIRST!

Hazardous fl uids

can cause fi re

or explosions,

burns or death

could result.

Extremely hot

- Severe burns

can occur on

contact.

Biohazard can

cause serious

personal injury.

Hazardous fl uids

can Hazardous

pressure,

eruptions or

explosions could

cause personal

injury or property

damage.

Rotating

machinery

Amputation

or severe

laceration

can result.

Hazardous

voltage can

shock, burn or

cause death.

Other brand and product names are trademarks or registered trademarks of their respective holders.

® Barnes is a registered trademark of Crane Pumps & Systems, Inc.

2002, 2003, 6/2004, 5/06, 9/06 Alteration Rights Reserved

INSTALLATION: Do not work on pump until power is

unplugged. Do not cut o ground pin or use an adapter

tting. Do not use an extension cord. Do not position the

pump into a unidenti ed site which you don’t know the

Max. Diameter particles mixed with water. The pump cord

should be connected to a separately fused, grounded line

with a minimum capacity of 15 amps (or GFCI Plug). It can

be connected to a non-fuse breaker as the recommended

amps. Never touch the pump when it is connected to

electrical power.

Before installing or servicing this pump, be certain pump 1.

power source is disconnected.

Installation and electrical wiring must be completed 2.

before priming pump. Check appropriate community

agencies, or contact local electrical and pump

professionals.

Call an electrician when in doubt. Pump should be 3.

connected to a separate GFCI plug or 15 amps circuit

breaker or 15 amps fuse block. Note that, plugging into

existing outlets may cause low voltage at motor, causing

blown fuses, tripping of motor overload, or burned out

motor.

A permanent ground connection from pump to the 4.

grounding bar at the service panel is mandatory. Pumps

come with a grounding conductor and a grounding-

type attachment plug. Do not connect pump to a power

supply until permanently grounded. For maximum

safety, ground pump to a circuit equipped with a fault

interrupter device.

Before installing pump, clear sump basin of any water, 5.

debris, or sediment, you had better add strainer in the

inlet hole to protect inners. Warning: Sump basin must

be vented in accordance with local plumbing codes.

Pumps are not designed for and CANNOT be installed in

locations classi ed as hazardous.

The following may cause severe damage to pump and 6.

will void warranty:

Using an extension cord.•

Cutting o the ground pin or using an adapter tting.•

Removing motor housing, unscrewing impeller, or •

otherwise removing impeller seal.

Pumping chemicals or corrosive liquids.•

Pumping other ammable liquids.•

Pumping hot liquids (exceed 40 centigrade)(over •

104°F).

When the pump reaches thermal overload, it will shut-•

o automatically. Once it cools down-either naturally

or by being cool down by air near 20 minutes, it will

restart.

Do not submerge the pump or motor in water. Do not •

operate this product while unattended.

The simple way to connect this Utility Pump:7.

Step 1:• Connect a standard discharge dia. pvc, steel,

or stainless steel pipe tting to this pump inlet and

discharge.

Step 2:• Place the inlet into the tank or bucket where

the uid needs to be pumped (add strainer before the

inlet).

Step 3:• Be sure to ll the casing with water prior to

running the pump.

Step 4:• Move away from the area to be pumped, and

stand on dry ground.

Loading ...