Loading ...

Loading ...

Loading ...

Determine vent path

• Select the route that will provide the straightest and most

direct path outdoors.

• Plan the installation to use the fewest number of elbows and

turns.

• When using elbows or making turns, allow as much room as

possible.

• Bend vent gradually to avoid kinking.

• Use the fewest 90 ° turns possible.

Determine vent length and elbows needed for best

drying performance

• Use one of the following Vent system charts to determine

type of vent material and hood combinations acceptable to

use.

NOTE: Do not use vent runs longer than those specified in

the Vent system charts. Exhaust systems longer than those

specified will:

• Shorten the life of the dryer.

• Reduce performance, resulting in longer drying times and

increased energy usage.

The Vent system charts provide venting requirements that will

help to achieve the best drying performance.

Vent system chart 1 - rigid metal vent only

Number of Type of Box or Angled

90° turns vent Iouvered hoods

or elbows hoods

0 Rigid metal 174 ft (53.0 m) 168 ft (51.2 m)

1 Rigid metal 164 ft (50.0 m) 158 ft (48.0 m)

2 Rigid metal 154 ft (46.9 m) 148 ft (45.1 m)

3 Rigid metal 145 ft (44.2 m) 139 ft (42.4 m)

4 Rigid metal 137 ft (41.8 m) 131 ft (39.9 m)

Vent system chart 2 - rigid metal vent used with a

maximum of 8 ft (2.4 m) flexible metal vent

Number of Type of Box or Angled

g0° turns vent Iouvered hoods

or elbows hoods

0 Rigid metal t44 ft (43.9 m) 138 ft (42.1 m)

1 Rigid metal 134 ft (40.8 m) 128 ft (39.0 m)

2 Rigid metal 125 ft (38.1 m) 119 ft (36.3 m)

3 Rigid metal 117 ft (35.7 m) 111 ft (33.8 m)

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

1. Position the dryer so that the rear of the dryer is within 4 ft

(1.2 m) of its final location.

2. Install exhaust hood. Use caulking compound to seal exterior

wall opening around exhaust hood.

3. Connect vent to exhaust hood. Vent must fit inside exhaust

hood. Secure vent to exhaust hood with 4" (10.2 cm) clamp.

4. Run vent to dryer location. Use the straightest path possible.

See "Determine vent path" in "Plan Vent System." Avoid 90°

turns. Use clamps to seal all joints. Do not use duct tape,

screws or other fastening devices that extend into the interior

of the vent to secure vent.

1.

2.

Remove the blue cap from the gas pipe. Move the dryer close

to its final location.

Using a wrench to tighten, connect the gas supply to the

dryer. Use pipe-joint compound on all non-flared male

threads. Ifflexible metal tubing is used, be sure there are no

kinks.

NOTE: For LP gas connections, you must use pipe-joint

compound resistant to the action of LP gas. Do not use

TEFLON _ttape.

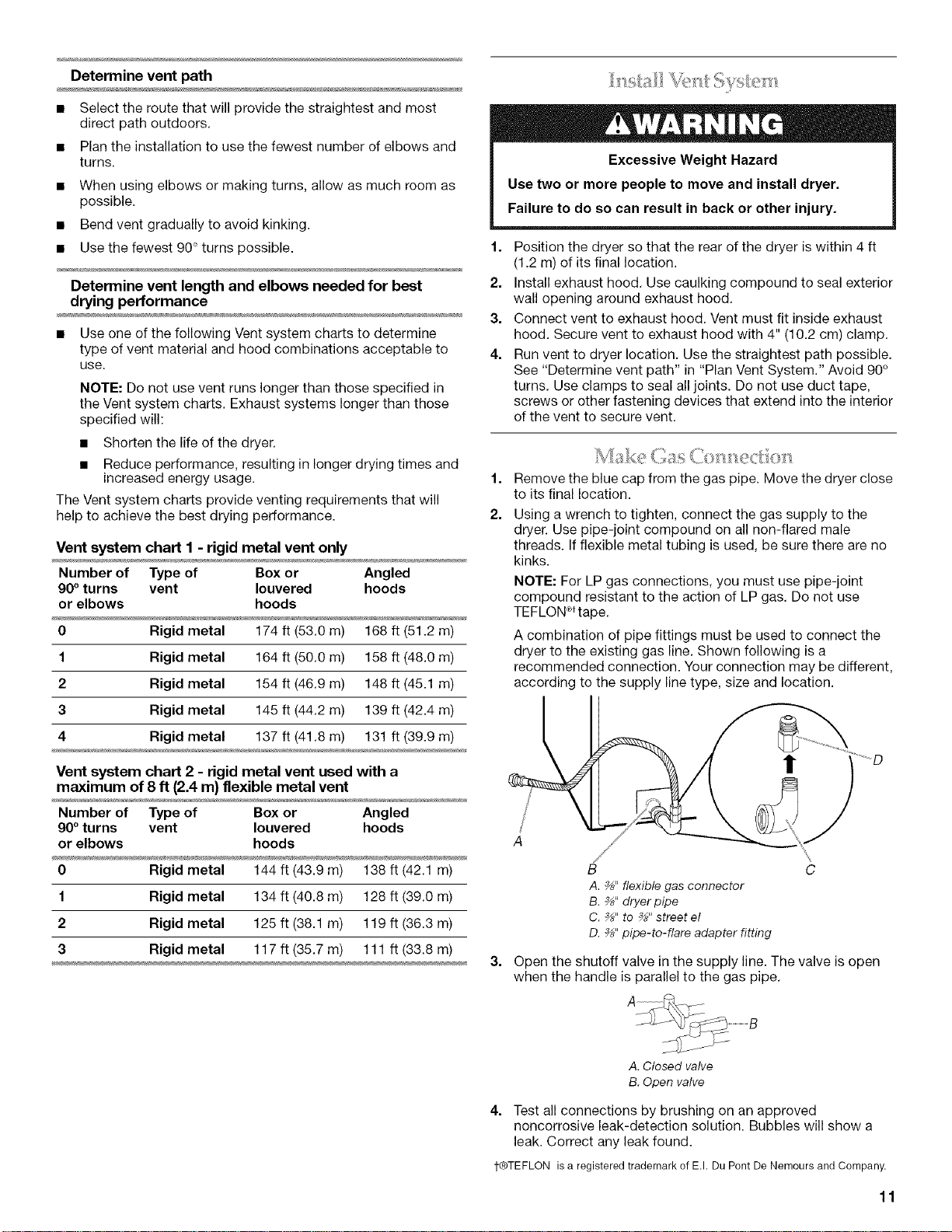

A combination of pipe fittings must be used to connect the

dryer to the existing gas line. Shown following is a

recommended connection. Your connection may be different,

according to the supply line type, size and location.

3.

B

A. _" flexible gas connector

B. _" dryer pipe

C. _" to _" street el

D. _" pipe-to-flare adapter fitting

a

Open the shutoff valve in the supply line. The valve is open

when the handle is parallel to the gas pipe.

A. Closed valve

B. Open valve

4. Test all connections by brushing on an approved

noncorrosive leak-detection solution. Bubbles will show a

leak. Correct any leak found.

1@TEFLON isa registered trademark of E.I.Du Pont De Nemours and Company.

11

Loading ...

Loading ...

Loading ...