Loading ...

Loading ...

Loading ...

15

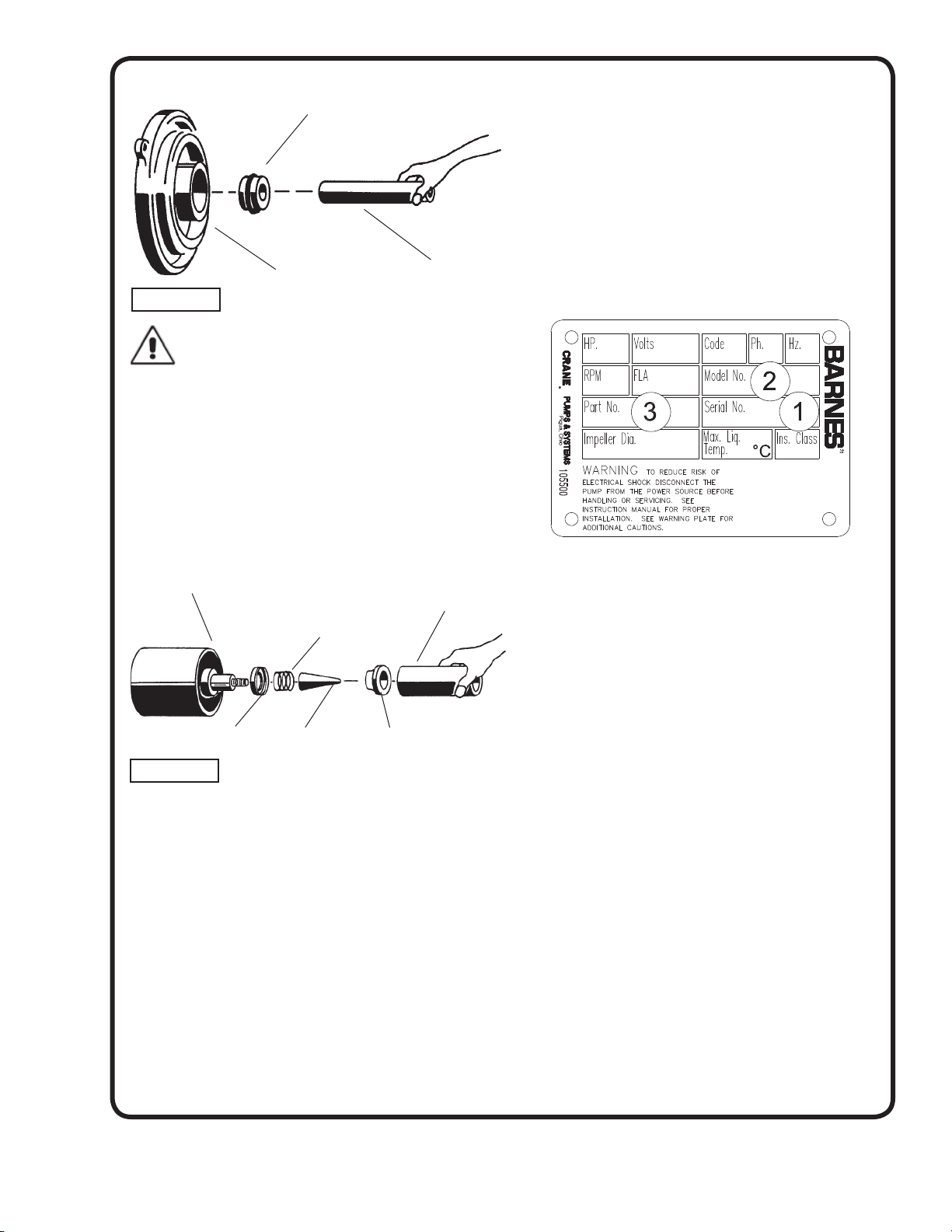

DO NOT HAMMER ON THE SEAL PUSHER - IT

WILL DAMAGE THE SEAL FACE.

Place spring retainer and spring onto motor shaft. Lightly

oil shaft (DO NOT use grease) and inner surface of

bellows of rotating member. With fi nished end away from

motor, slide rotating member over bullet and onto shaft

until it engages spring (see Fig. 13). Carefully assemble

shaft to seal plate as per section F-3.3. It is extremely

important to keep seal faces clean during assembly. Dirt

particles lodged between these faces will cause the seal

to leak. When seal plate is assembled to motor, it will

properly align and seat the seal (3) and bearing (4). Follow

complete reassembly instructions as per section F-3.3.

F-4.3) Replacing Exclusion Seal:

The exclusion seal (16), helps to keep debris away from

the shaft seal where it could cause damage. The exclusion

seal should be replaced whenever the shaft seal is

replaced. To replace the exclusion seal, pull the old seal off

the shaft, and slide the new seal on with the thin lip toward

the motor. Be sure not to damage the lip of the seal. Finger

pressure is all that is needed to install the exclusion seal.

SECTION: G REPLACEMENT PARTS

G-1 ORDERING REPLACEMENT PARTS:

When ordering replacement parts, ALWAYS furnish the

following information:

1. Pump serial number and date code. (Paragraph G-4)

2. Pump model number. (Paragraph G-3)

3. Pump part number. (Paragraph G-2)

4. Part description.

5. Item part number.

6. Quantity required.

7. Shipping instructions.

8. Billing Instructions.

G-2 PART NUMBER:

The part number consists of a six (6) digit number, which

appears in the catalog. A one or two letter suffi x may follow

this number to designate the design confi guration. This

number is used for ordering and obtaining information.

G-3 MODEL NUMBER:

This designation consists of numbers and letters which

represent the discharge size, series, horsepower, motor

phase and voltage, speed and pump design. This number is

used for ordering and obtaining information.

G-4 SERIAL NUMBER:

The serial number block will consist of a six digit number,

which is specifi c to each pump and may be preceded by

an alpha character, which indicates the plant location.

This number will also be suffi xed with a four digit number,

which indicates the date the unit was built (Date Code).

EXAMPLE: A012345 0490.

Reference the six digit portion (Serial Number) of this

number when referring to the product.

Seal Pusher

Seal Plate

Stationary Member

(3d) Polished Face Out

Rotating Member (3c)

Motor, Sleeve &

Bearing

Bullet

Seal Pusher

FIGURE 11

FIGURE 13

Spring

Retaining Ring (3a)

Loading ...

Loading ...

Loading ...